Continuous and repeated bending-bending extrusion cycle remanufacturing method for waste titanium alloy chips

A technology of repeated bending and manufacturing methods, applied in the field of metal material processing, to achieve the effect of eliminating microscopic defects, realizing full densification, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

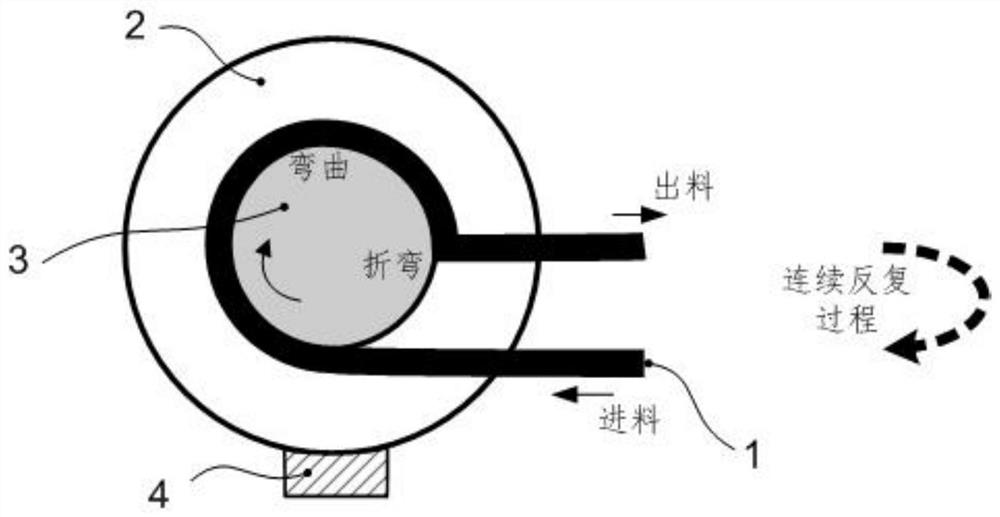

[0026] to combine figure 1 As shown, the waste titanium alloy chips proposed by the present invention are continuously and repeatedly bent-bending and extruding cyclic remanufacturing method, comprising the following steps:

[0027] S1. Titanium alloy chip recycling pretreatment: Clean the titanium alloy chip raw material with ethanol to remove oil and impurities in the raw material. The chip raw material is made of grade 5 (ASTM Grade 5) titanium alloy obtained through end milling (ie Ti- 6Al-4V) generated chips, cleaning adopts the method of ultrasonic cleaning, cleaning in the ultrasonic vibration tank, the preferred ethanol used is 99.9% ethanol;

[0028] S2, titanium alloy swarf encapsulation and room temperature cold roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com