Modified paste filler based on magnesium oxychloride gelling system and preparation method

A technology of magnesium oxychloride and filler, applied in the field of building materials, can solve the problems of strength shrinkage, poor performance, moisture absorption and halogen return, and achieve the effects of increasing stability, increasing pH value, and increasing reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

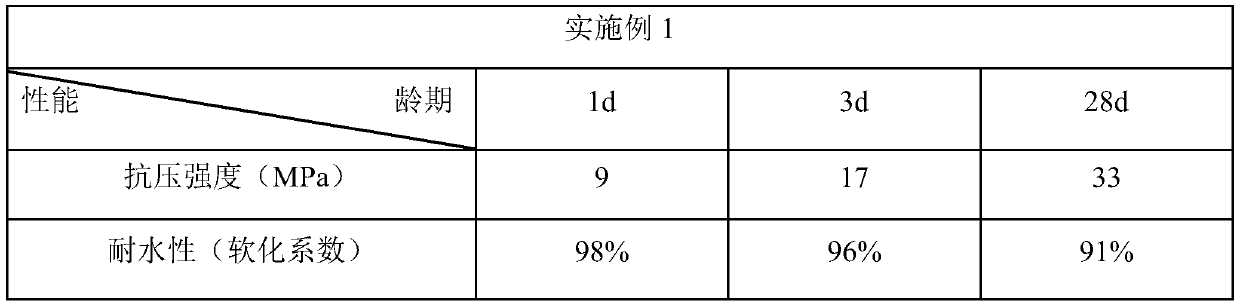

Embodiment 1

[0042] A modified paste filler based on the magnesium oxychloride gelling system, consisting of the following components in weight percent:

[0043] 28% of brine, 30% of tailing salt, 32% of magnesium oxide, 3% of rice husk ash, 2% of kaolin-based gangue fluidized bed ash, 0.5% of SHMP complex catalyst, 2% of redispersible rubber powder, M-tuning Mixture 0.5%, whiskers 2%.

[0044] Its preparation method comprises the following steps:

[0045] S1. According to the formula of the above-mentioned modified paste filler based on the magnesium oxychloride gelling system, each component is weighed for subsequent use;

[0046] S2, magnesium oxide, whiskers, bittern (magnesium chloride concentration is 28.0%) is carried out uniform stirring 8min, obtains uniform slurry;

[0047] S30. Grinding the kaolin-based gangue fluidized-bed ash in a ball mill with a rotational speed of 220r / min for 45 minutes to obtain activated kaolin-based gangue fluidized-bed ash.

[0048] S3, uniformly mi...

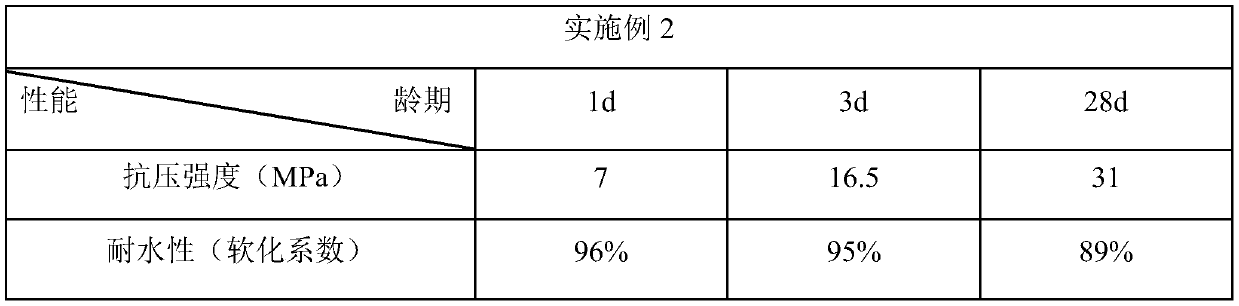

Embodiment 2

[0056] A modified paste filler based on the magnesium oxychloride gelling system, consisting of the following components in weight percent:

[0057] 25% brine, 22% tail salt, 40% magnesium oxide, 1% rice husk ash, 1% kaolin-based gangue fluidized bed ash, 0.8% SHMP complex catalyst, 4% redispersible rubber powder, M-tuning Mixture 1.2%, whiskers 5%.

[0058] Its preparation method comprises the following steps:

[0059] S1. According to the formula of the above-mentioned modified paste filler based on the magnesium oxychloride gelling system, each component is weighed for subsequent use;

[0060] S2, magnesium oxide, whiskers, brine (magnesium chloride concentration is 32.0%) is carried out uniform stirring 10min, obtains uniform slurry;

[0061] S30. Grinding the kaolin-based gangue fluidized-bed ash in a ball mill with a rotational speed of 230r / min for 40 minutes to obtain activated kaolin-based gangue fluidized-bed ash.

[0062] S3, uniformly mixing rice husk ash, kaoli...

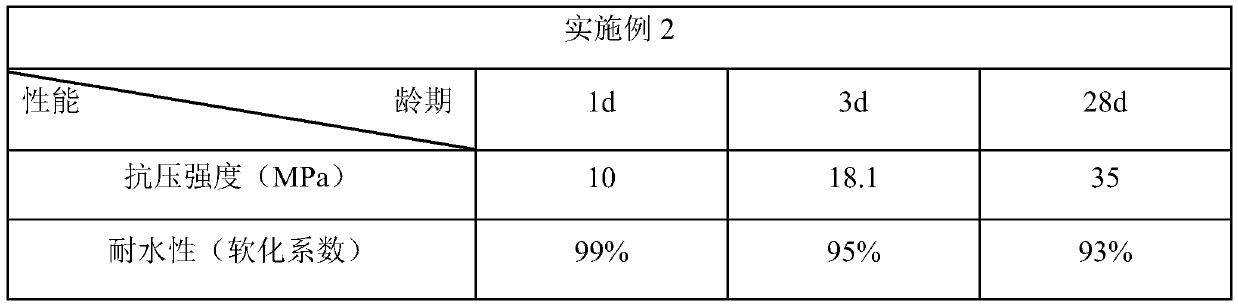

Embodiment 3

[0070] A modified paste filler based on the magnesium oxychloride gelling system, consisting of the following components in weight percent:

[0071] 30% brine, 20% tail salt, 35% magnesium oxide, 5% rice husk ash, 5% kaolin-based gangue fluidized bed ash, 1% SHMP complex catalyst, 1% redispersible rubber powder, M-tuning Mixture 2%, whiskers 1%.

[0072] Its preparation method comprises the following steps:

[0073] S1. According to the formula of the above-mentioned modified paste filler based on the magnesium oxychloride gelling system, each component is weighed for subsequent use;

[0074] S2, magnesium oxide, whiskers, brine (magnesium chloride concentration is 20%) is carried out uniform stirring 10min, obtains uniform slurry;

[0075] S30. Grinding the kaolin-based gangue fluidized-bed ash in a ball mill with a rotating speed of 240r / min for 40 minutes to obtain activated kaolin-based gangue fluidized-bed ash.

[0076] S3, uniformly mix rice husk ash, kaolinite gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com