A polymer binder with high peel strength and its application in secondary lithium batteries

A polymer, high-stripping technology, used in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of mechanical properties (poor elastic modulus, low solubility of organic solvents, electrode delamination or peeling, etc.), and achieve excellent performance. , The effect of easy availability of raw materials and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Polymer Binder A1:

[0043] The cathode active material lithium nickel manganate, Super P and binder A1 precursor [(Nu1 (m=44, 60% of the total polymer mass) and polyvinyl carbonate (40% of the total polymer mass)] were added to the mortar at a mass ratio of 8:1:1 as a slurry, added NMP (accounting for 10% of the mass of the slurry) continued to grind and stir at 30° C. for 20 min to obtain a uniform slurry. The above slurry was evenly coated on aluminum foil, dried in an oven at 60°C for 2 hours, shot into a suitable size pole piece by a gun slicer, continued to dry in an oven at 100°C for 24 hours, and placed in a glove box for use.

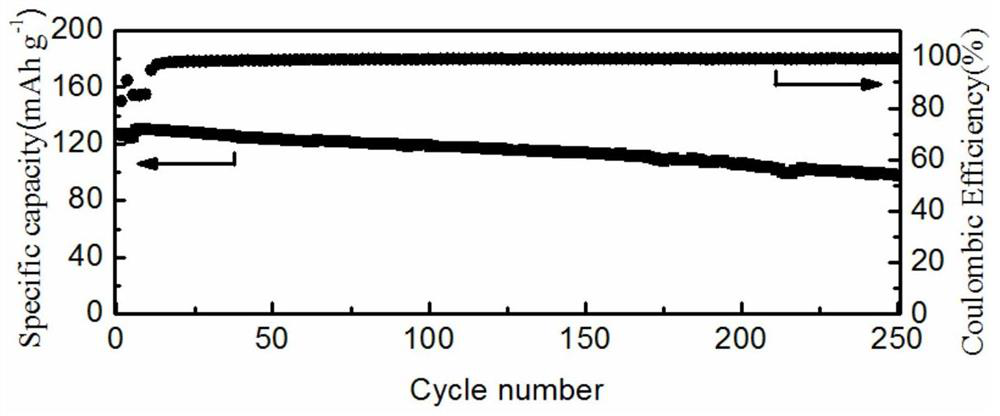

[0044] The electrode obtained above is used as the positive electrode, and the graphite is assembled as the negative electrode to obtain a lithium nickel manganate / / graphite full battery, and its room temperature long cycle performance and peel strength at 0.5C are detected (see figure 1 and Table 1), by figure 1 It ca...

Embodiment 2

[0050] Preparation of Polymer Binder A2:

[0051] Put Nu2 (10% of the total polymer mass) and polyethylene carbonate (90% of the total polymer mass) were dissolved in acetonitrile (80% of the mass of the slurry), and the reaction was stirred at 100 ° C for 2 h to prepare A solution of polymer binder A2 was obtained.

[0052] High peel strength polymer binder based electrodes:

[0053] The positive electrode active materials sulfur, graphite and the acetonitrile solution of the polymer binder A2 obtained above were ground and stirred in a mortar in a mass ratio of 70:5:25 to form a uniform slurry. The above slurry was evenly coated on aluminum foil and dried in an oven at 60°C for 0.5h. The pole pieces of the appropriate size are formed by the gun tablet machine, and then continue to be dried in an 80 ℃ oven for 12 hours.

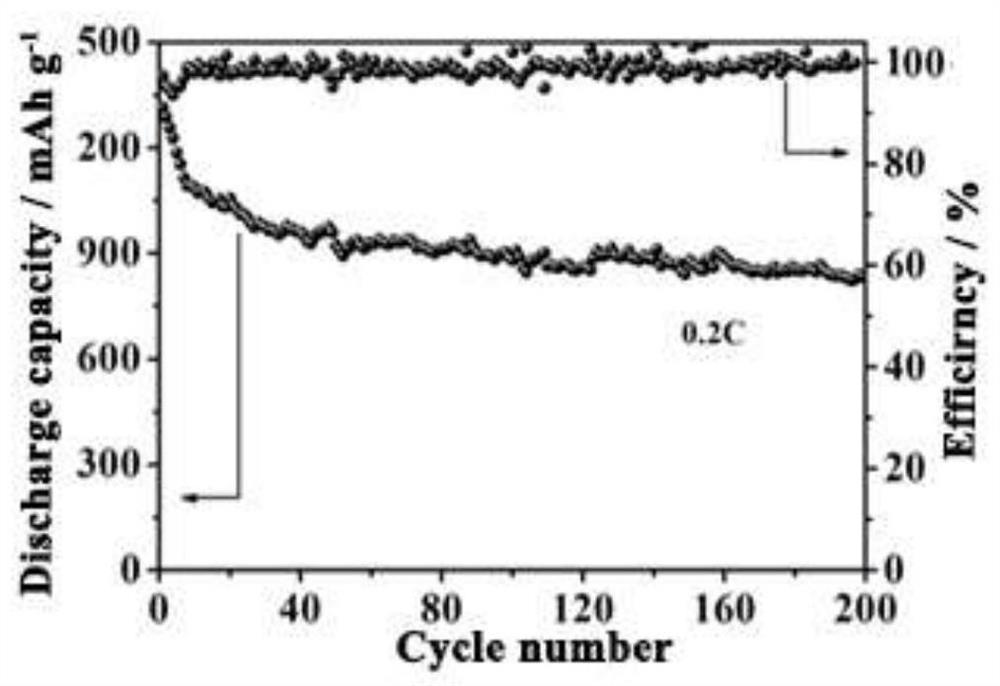

[0054] The above-obtained electrode was used as the positive electrode, and lithium was used as the negative electrode to assemble, and the sulfur / / lit...

Embodiment 3

[0059] Preparation of Polymer Binder A3:

[0060] structure Nu3 as (33% of the total polymer mass) and poly(vinylidene carbonate) (67% of the total polymer mass) were dissolved in tetrahydrofuran (80% by mass of the slurry), and the reaction was stirred at -10°C A solution of polymer binder A2 was prepared in 2 min. High peel strength polymer binder based electrodes:

[0061] The ternary positive electrode material, acetylene black and the tetrahydrofuran solution of the polymer binder A3 obtained above were ground and stirred in a mortar in a mass ratio of 6.5:1.8:1.7 to form a uniform slurry. The above slurry was uniformly coated on aluminum foil and dried in an oven at 60°C for 20 min. Pole pieces of suitable size are shot by a shotgun machine, continue to be dried in a 60 ℃ vacuum oven for 12 hours, and placed in a glove box for future use.

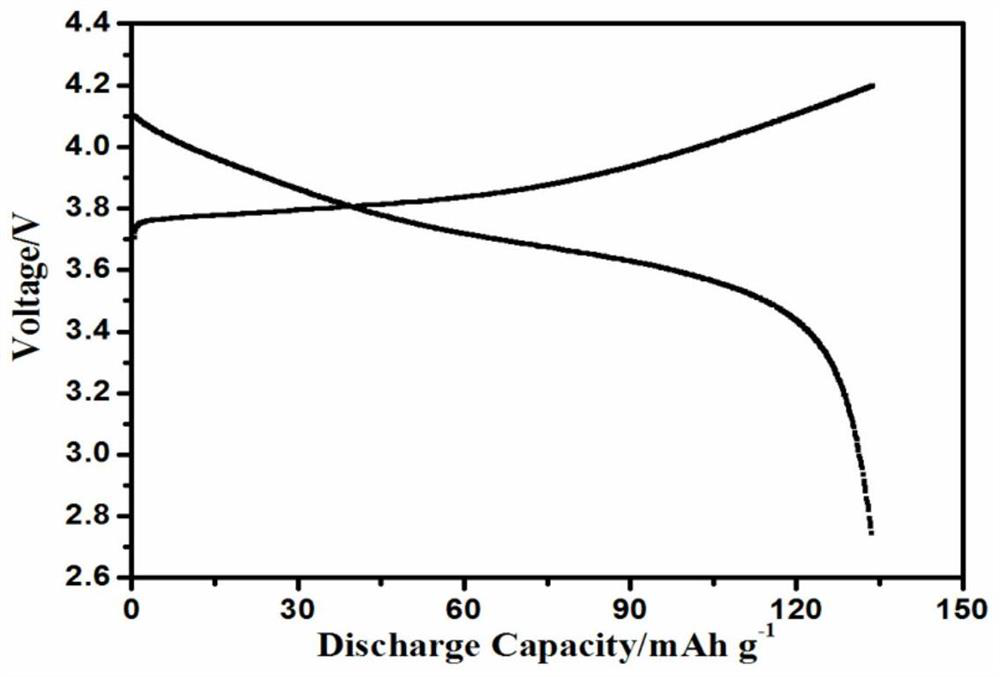

[0062] The above-obtained electrode was used as the positive electrode, and lithium was used as the negative electrode to assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com