Non-dismounting nonmetal bottom plate solid mold composite slab, corresponding floor structure and floor construction method

A laminated board, non-metal technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problem of low bonding strength between blocking materials and surrounding materials, large workload of metal plate removal, and inability to form protective layer thickness, etc. It can reduce the investment of production equipment and facilities, save the dismantling process, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings.

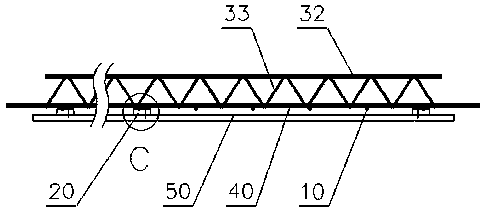

[0033] like Figure 1-18As shown, the non-demolition-free non-metal base plate solid-form laminated board (referred to as the fixed-form laminated board) provided by the present invention includes a base plate 50, a steel truss 30 and a steel mesh located above the base plate, and the steel mesh can be arranged on the steel truss and the steel mesh. Between the cushion blocks, in order to facilitate processing, the bottom plate is made of a non-metallic plate, and there is a gap between the bottom plate of the steel bar truss and the upper surface of the bottom plate.

[0034] There is no precast concrete layer for this kind of solid-form laminated board, especially for the strength of the bottom plate, but it can be sprayed with an interface layer, an oxygen-insulating fire-proof layer or an anti-corrosion layer according to actual needs.

[0035] The steel bar truss c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com