Conductive composite fiber yarn and its continuous preparation method and application

A technology of conductive composite fibers and nanofibers, applied in the direction of fiber processing, fiber type, yarn, etc., can solve the problems of agglomeration and distribution of metal nanowires, limited promotion and application, complicated operation process, etc., and achieve excellent conductivity sensitivity and good conductivity. Sensitivity, the effect of huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

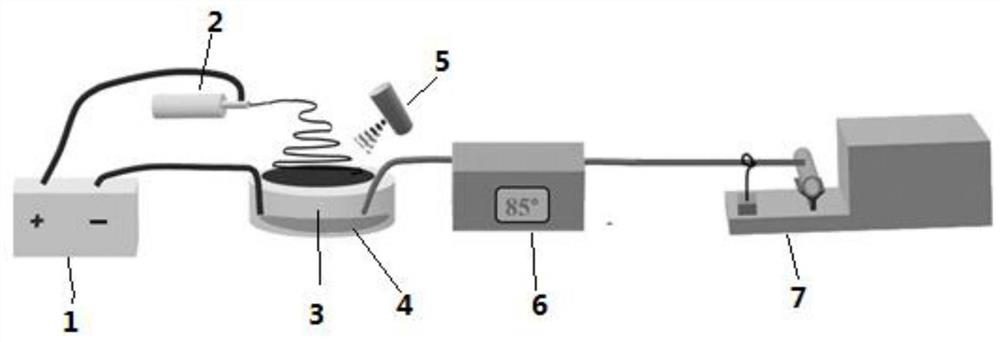

[0044] see figure 1 Shown, a kind of preparation method of conductive composite fiber yarn comprises the steps:

[0045] S1, preparation solution:

[0046] S11, dissolving polyurethane in N, N-dimethylformamide solvent, preparing a spinning solution with a mass fraction of PU of 25 wt%, and stirring on a magnetic stirrer for 4 hours;

[0047] S12. Prepare a silver nanowire dispersion, wherein the silver nanowire mass fraction is 1 wt%, and then ultrasonically treat the dispersion for 1 hour, the ultrasonic frequency is 20kHz, and the power is 400W;

[0048] S13. Prepare fatty alcohol polyoxyethylene ether O-20, deionized water, and ethanol ternary mixed solution, and the volume ratio of the three is 0.5:20:80, then stir the ternary mixed solution with a magnetic stirrer for 2 hours, and use as Bath;

[0049] S2, wet electrospinning treatment: the spinning solution prepared in step S11 is electrospun at a voltage of 10-15kV, and the distance from the spinneret to the collect...

Embodiment 2-5

[0060] The difference between Examples 2-5 and Example 1 lies in that the mass fraction of silver nanowires is changed, and other steps are basically the same as Example 1, which will not be repeated here.

[0061] The mass fraction of silver nanowires and the performance of the prepared conductive composite fiber yarn in Table 1 Example 1-5

[0062]

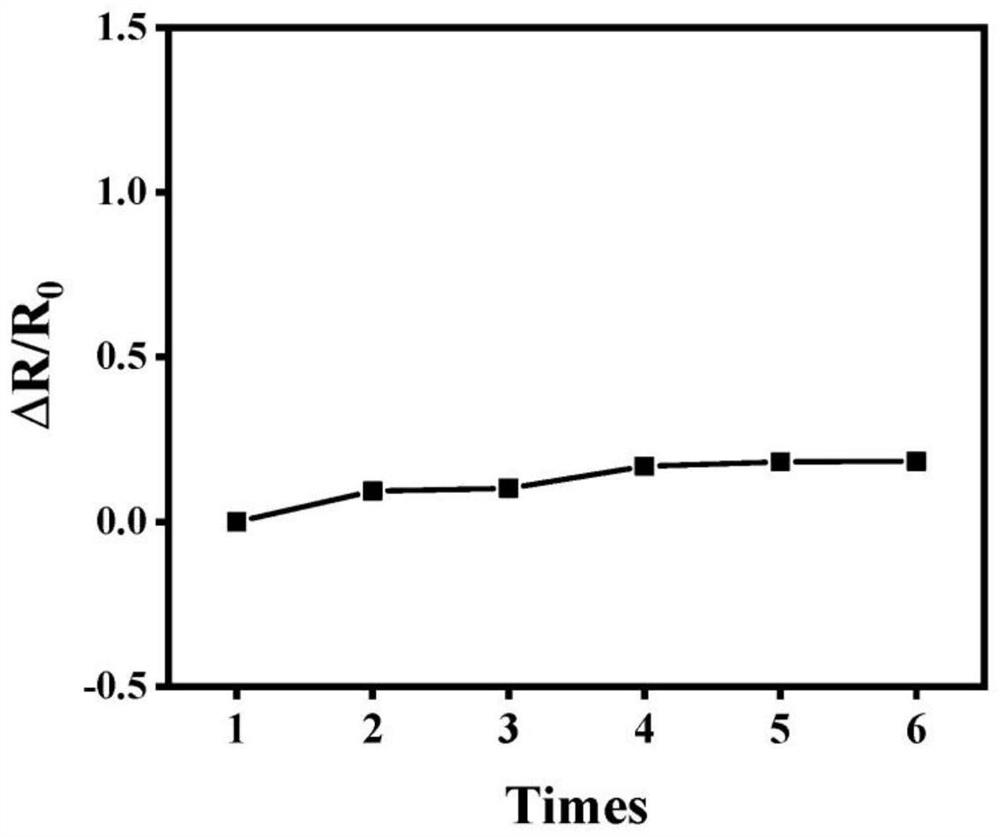

[0063] According to Table 1, it can be seen that with the increase of the mass fraction of silver nanowires, the electrical conductivity, elongation at break and breaking strength of the prepared conductive composite fiber yarns gradually increased, while the pure polyurethane fiber yarn prepared in Comparative Example 1 did not It does not have electrical conductivity, which proves that the electrical conductivity of the conductive composite fiber yarn has been significantly improved while ensuring excellent mechanical properties.

Embodiment 6-8

[0065] The difference between embodiment 6 and embodiment 1 is that the distance from the spinneret to the collector is 10 cm. Other steps are basically the same as those in Embodiment 1, and will not be repeated here.

[0066] The difference between Example 7 and Example 1 is that the ternary mixed solution covers to a depth of 2 cm. Other steps are basically the same as those in Embodiment 1, and will not be repeated here.

[0067] The difference between Example 8 and Example 1 is that the heating temperature is 80°C. Other steps are basically the same as those in Embodiment 1, and will not be repeated here.

[0068] The performance of the conductive composite fiber yarn prepared by table 2 embodiment 1 and embodiment 6-8

[0069]

[0070]

[0071] It is worth noting that when the mass fraction of polyurethane (PU) is lower than 15wt%, PU can be well dissolved in organic solvents, but because the concentration of the mixture is too low, it is difficult to prepare co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance per length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com