A kind of glass fiber reinforced polycarbonate composite material and its preparation method and application

A technology of polycarbonate and composite materials, which is applied in the field of engineering plastics, can solve the problems of limitation, reducing the fluidity of composite materials, low toughness, etc., and achieve the goal of reducing dielectric loss, excellent high modulus and high toughness characteristics, and excellent processing performance Effect

Active Publication Date: 2021-11-05

KINGFA SCI & TECH CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the existing glass fiber reinforced polycarbonate composites have the contradiction of high rigidity but low toughness, and the conventional toughening method is to directly add toughening agent, which will also greatly reduce the fluidity of the composite material, and the composite material The improvement of rigidity and toughness is also very limited, and due to the inherent dielectric loss application characteristics of polycarbonate, its application in the automotive, electrical and electronic, communication industry, construction industry and other fields is severely limited, especially in the 5G communication industry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

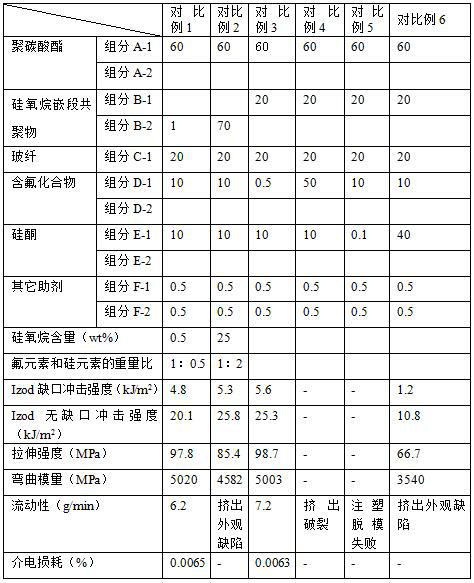

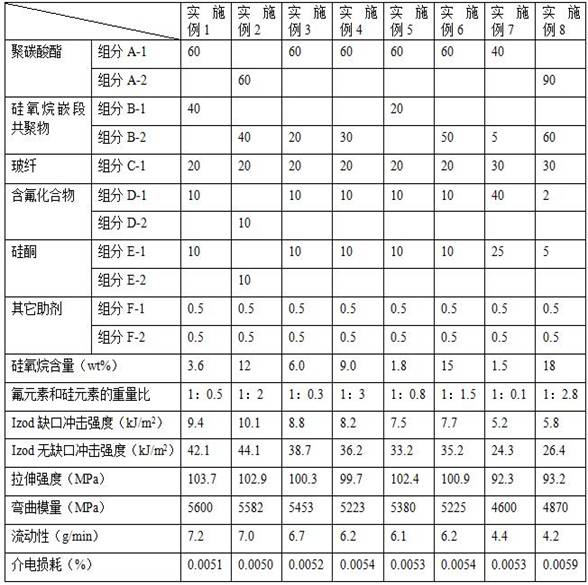

Embodiment 1-8 and comparative example 1-6

[0063] Examples 1-8 and Comparative Examples 1-6: Preparation of Glass Fiber Reinforced Polycarbonate Composite Materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a glass fiber reinforced polycarbonate composite material and its preparation method and application, comprising the following composition: Component A: 40-90 parts of polycarbonate; Component B: polysiloxane block copolymer 5-60 parts; Component C: 5-30 parts of glass fiber; Component D: 2-40 parts of fluorine-containing compound; Component E: 1-30 parts of silicone. The present invention chooses to add specific content of polysiloxane block copolymer, fluorine-containing compound and silicone to the formula of glass fiber reinforced polycarbonate composite material, so as to ensure that the final prepared composite material has specific siloxane The content and the specific weight ratio of fluorine and silicon make the prepared composite material not only have excellent high modulus and high toughness characteristics, but also have excellent processing performance. Compared with conventional reinforcement modification methods, the composite material has both Rigid and tough, with high fluidity and significantly reduced dielectric loss, it is especially suitable for the 5G communication industry.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a glass fiber reinforced polycarbonate composite material and its preparation method and application. Background technique [0002] Polycarbonate resin PC is a thermoplastic engineering plastic with excellent comprehensive properties. In recent years, its high transparency, good flame retardancy, heat resistance, electrical insulation and dimensional stability, low water absorption and other characteristics have been widely used in automobiles, electronics, communications industries, construction industries, etc. field. With the expansion of its application fields, the impact strength, flexural modulus, tensile strength, fluidity, dielectric loss and other properties of polycarbonate have higher requirements. Pure polycarbonate or ordinary polycarbonate The material still cannot meet the requirements, therefore, the polycarbonate material needs to be modified. In ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L69/00C08L83/10C08L27/12C08L27/18C08L23/06C08L83/04C08K7/14C08J5/04

CPCC08J5/043C08J2369/00C08J2423/06C08J2427/12C08J2427/18C08J2483/04C08J2483/10

Inventor 李建军岑茵李明昆艾军伟陈勇文刘贤文吴俊丁超

Owner KINGFA SCI & TECH CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com