High voltage cable thermoplastic semiconducting shielding material and preparation method thereof

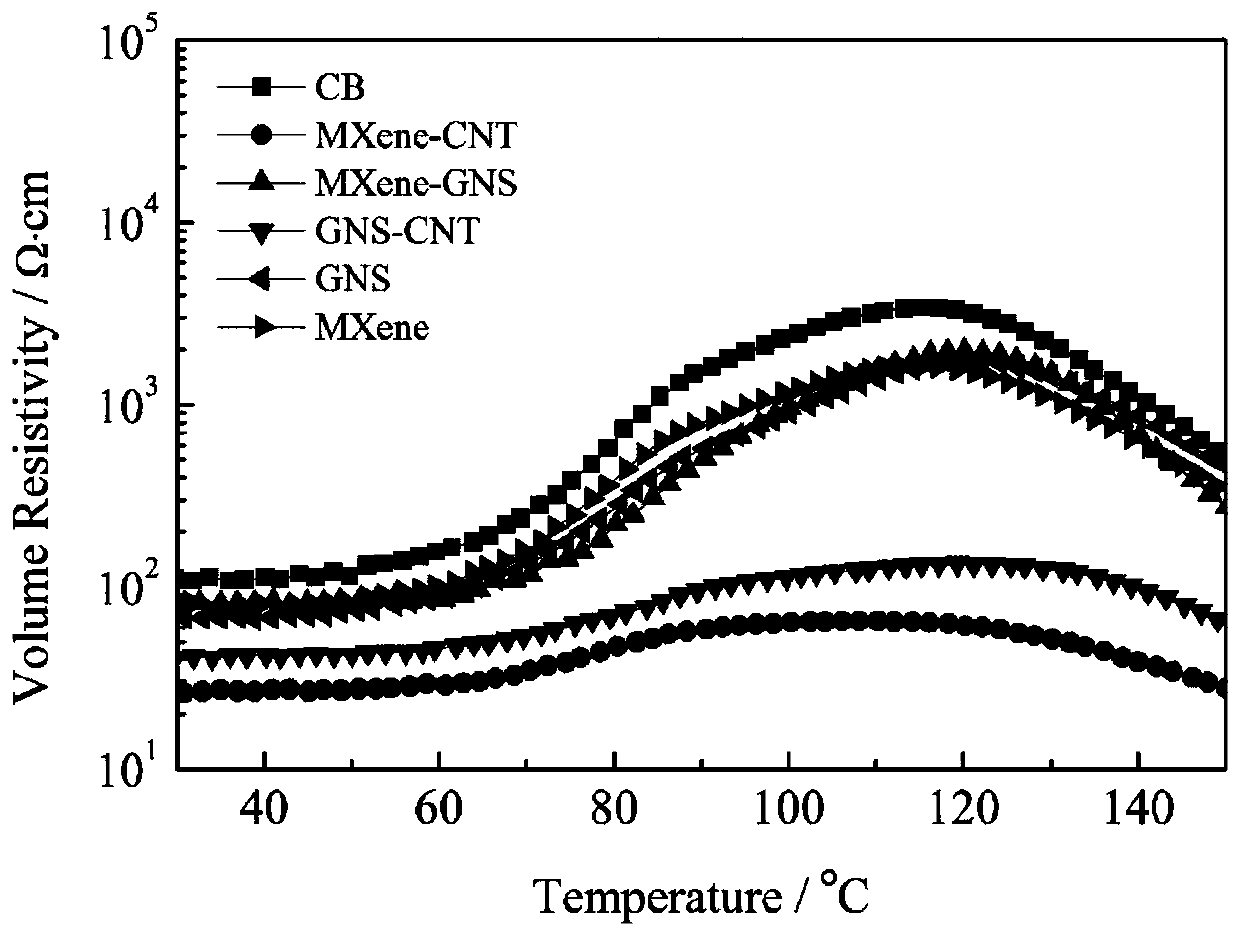

A technology for shielding materials and high-voltage cables, applied in the field of high-voltage cables, can solve problems such as low resistivity and low volume resistivity, and achieve the effects of improving stability, simple preparation process and reducing volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment relates to a thermoplastic semi-conductive shielding material for high-voltage cables; the material consists of 20 parts of polypropylene, 35 parts of ethylene-octene copolymer elastomer, 24 parts of conductive carbon black, 0.4 part of MXene-CNT composite conductive powder, Composed of 1.2 parts of lubricating dispersant and 0.5 parts of antioxidant.

[0049] The preparation method of the high-voltage cable thermoplastic semi-conductive shielding material comprises the following steps:

[0050] 1) Preparation of conductive masterbatch pellets containing carbon black:

[0051] 100 parts of grade 8200 ethylene-octene copolymer elastomer POE, 70 parts of nano conductive carbon black LK2017, 3.5 parts of lubricant ethylene bisoleic acid amide, 1.5 parts of antioxidant 4,4'-thiobis(6- tert-butyl-3-methylphenol), uniformly mixed in an internal mixer, the rotating speed is 50rpm, and the mixing temperature is 150°C. Immediately extrude and granulate with sin...

Embodiment 2

[0064] This embodiment relates to a semi-conductive shielding material for high-voltage cables; the material consists of 20 parts of polypropylene, 35 parts of ethylene-octene copolymer elastomer, 24 parts of conductive carbon black, 0.4 part of MXene-GNS composite conductive powder, 1.2 1 part lubricating dispersant, 0.5 part antioxidant.

[0065] The preparation method of the high-voltage cable thermoplastic semi-conductive shielding material comprises the following steps:

[0066] 1) The preparation of the conductive masterbatch pellets containing carbon black is the same as in Example 1.

[0067] 2) Preparation of MXene-GNS composite conductive powder:

[0068] Mix the 1 mg / mL ethanol solution of the MXene powder obtained by exfoliation with the 1 mg / mL graphene ethanol solution at a ratio of 1:1 to the mass ratio of the conductive component, ultrasonically disperse, filter, wash to remove ethanol, and freeze-dry to obtain MXene-GNS composite filler. The scanning electr...

Embodiment 3

[0073] This embodiment relates to a semi-conductive shielding material for high-voltage cables; the material consists of 20 parts of polypropylene, 35 parts of ethylene-octene copolymer elastomer, 24 parts of conductive carbon black, 0.4 part of GNS-CNT composite conductive powder, 1.2 1 part lubricating dispersant, 0.5 part antioxidant.

[0074] The preparation method of the high-voltage cable thermoplastic semi-conductive shielding material comprises the following steps:

[0075] 1) The preparation of the conductive masterbatch pellets containing carbon black is the same as in Example 1.

[0076] 2) Preparation of GNS-CNT composite conductive powder:

[0077] Disperse graphene and carbon nanotubes in 200ml of deionized water at a mass ratio of 3:1, 1:1, and 1:3, so that the concentrations of graphene and carbon nanotubes are both 1mg / mL, and add 1.6g Sodium dodecyl sulfonate, ultrasonically dispersed, filtered, washed to remove sodium dodecyl sulfonate, freeze-dried. Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com