Method for setting operating parameters of wire saw and the wire saw

A technology of operating parameters and setting methods, applied in the field of wire saws, can solve problems such as wire cutting, reduced processing accuracy, and input errors, and achieve the effect of preventing forgetting settings and setting errors, and high-precision processing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

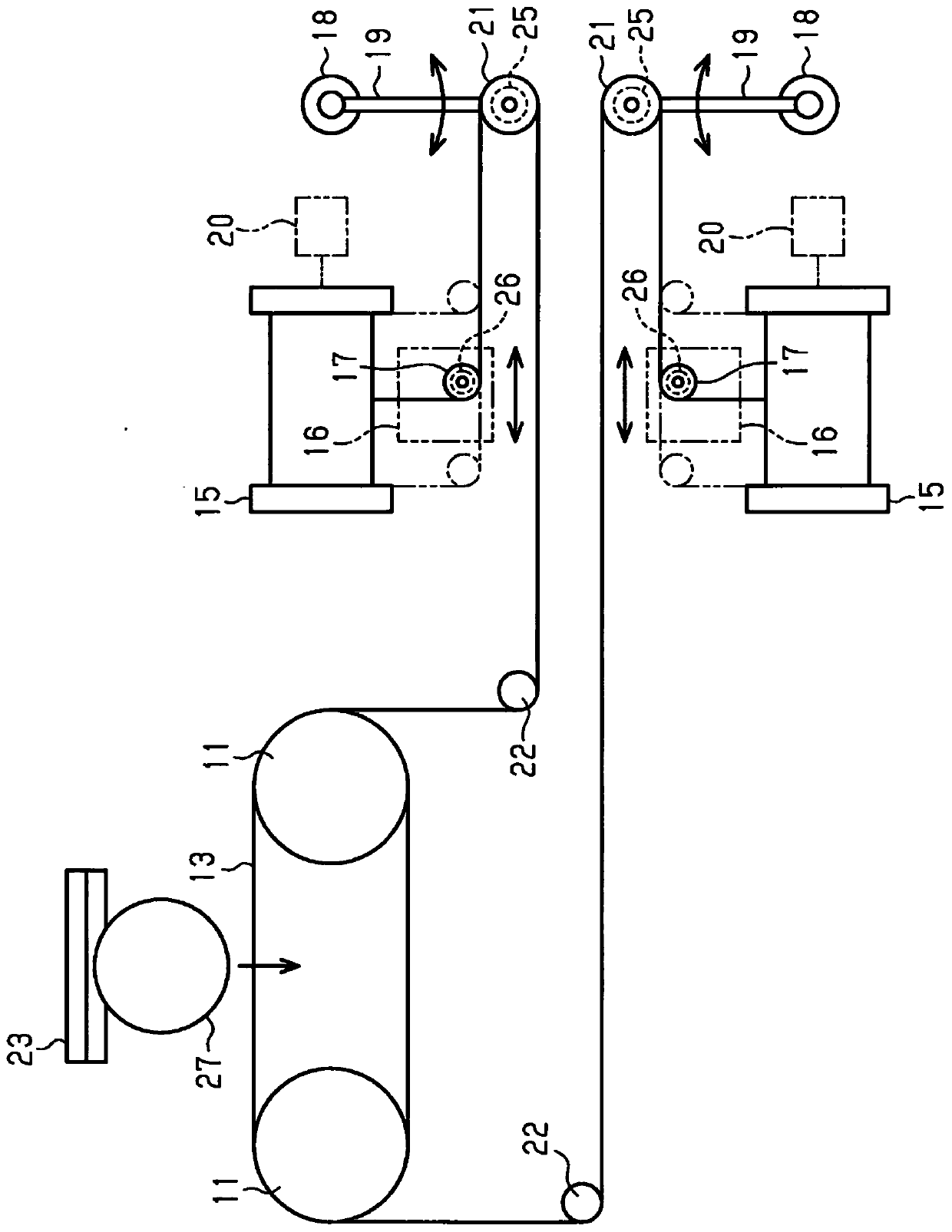

[0026] Below, according to Figure 1 to Figure 7 A wire saw (device) embodying the first embodiment of the present invention will be described.

[0027] Such as figure 1 As shown, a plurality of processing grooved rolls (hereinafter referred to as processing rolls) 11 are rotatably supported by a wire saw device frame (not shown) on parallel axes. Generally, two to four are mounted as the processing rollers 11, and two are mounted in this embodiment. A plurality of annular grooves (not shown) are formed at equal intervals on the outer periphery of the processing roller 11 , and a wire 13 for workpiece cutting is wound helically in the annular grooves. The wire rod 13 is a fixed abrasive wire rod, and the outer periphery of the carbon steel core wire of the wire rod 13 is fixed and held with abrasive grains such as diamond or white corundum using an adhesive.

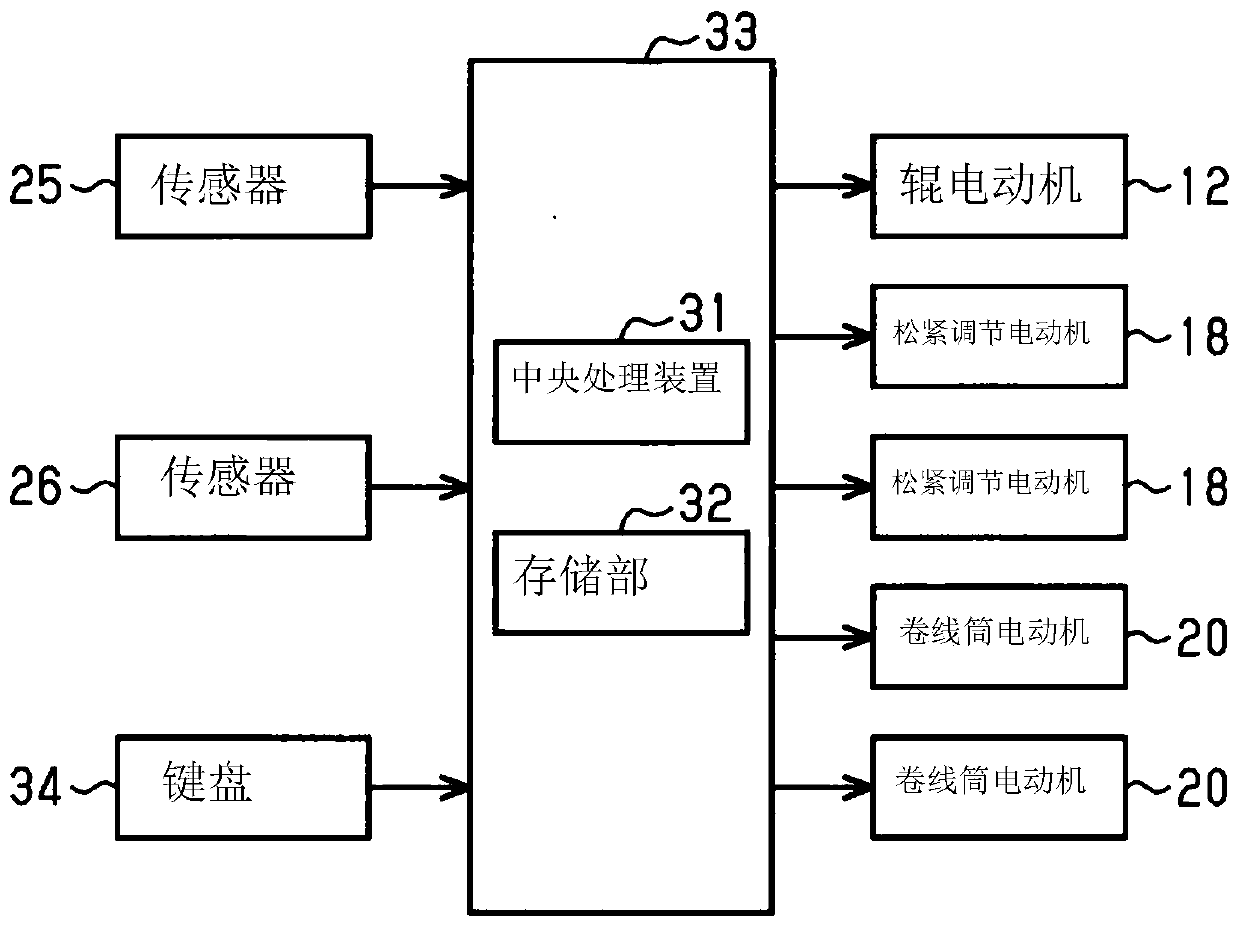

[0028] And, in this embodiment, one of the two processing rollers 11 passes figure 2 The motor 12 shown alternate...

no. 2 Embodiment approach

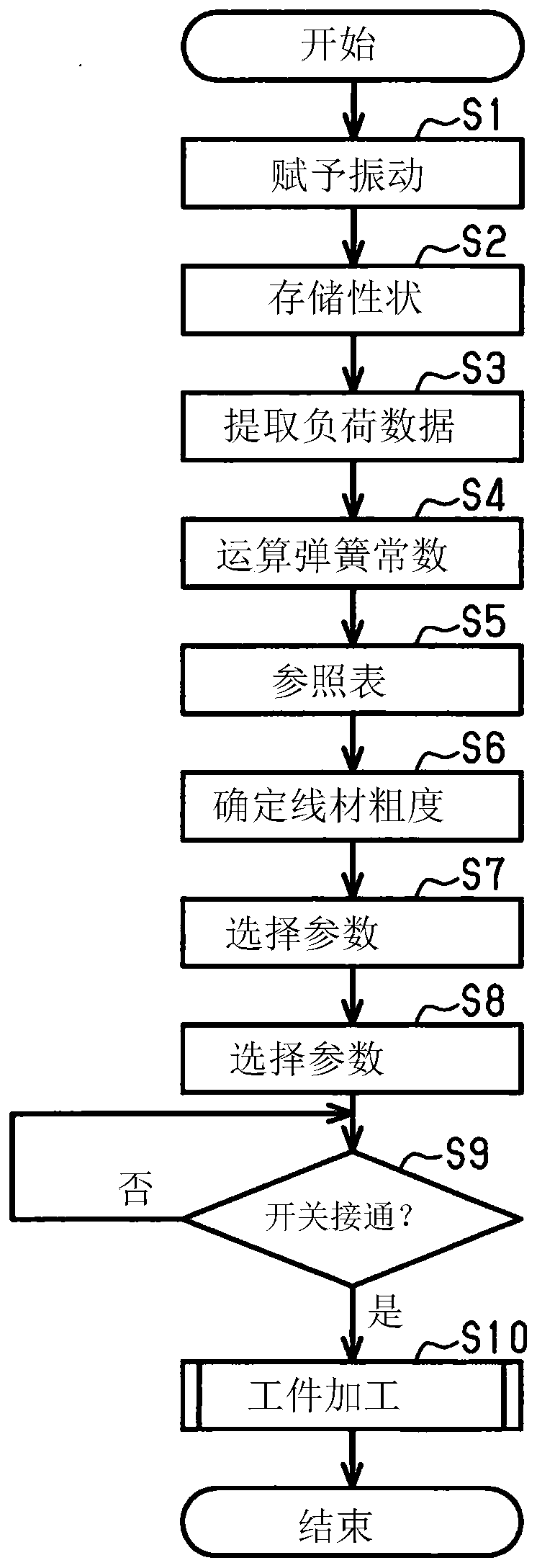

[0044] Next, according to Figure 5 with Figure 8 , the second embodiment of the present invention will be described focusing on the parts different from the first embodiment.

[0045] In the second embodiment, in order to judge the thickness of the wire 13, the physical attenuation characteristic of the wire 13 is detected. That is, in Figure 8 In the flow chart of , the property detection and storage of the wire 13 by the dancer arm 19 in S2 before the processing starts will be described. After the vibration of the dancer arm 19 ends, as Figure 5 As shown, the sensor 25 detects the convergence time β of the remaining stretching motion of the wire 13 as the property of the wire 13 in S2. That is, in Figure 8 In S11 shown, the CPU 31 recognizes the detection output of the sensor 25 indicating the convergence time β from the end of excitation to the convergence of the remaining expansion and contraction of the wire 13, and calculates the attenuation characteristic of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com