Adhesive for woodworking flat pasting

An adhesive, flat sticking technology, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problems of long curing time and unfavorable practical use, and achieve fast curing speed, good heat resistance, and stable peeling. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

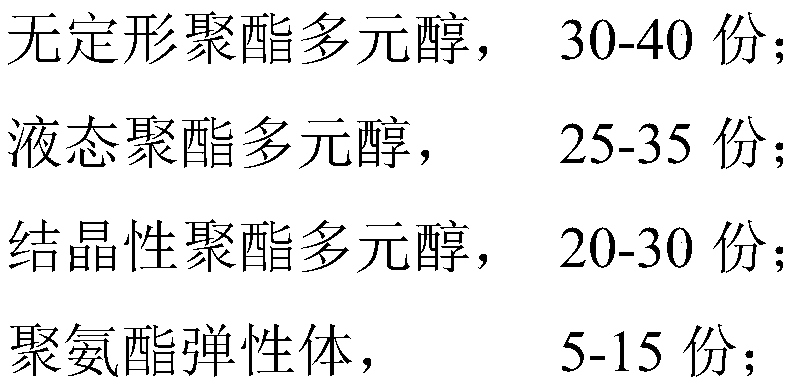

Method used

Image

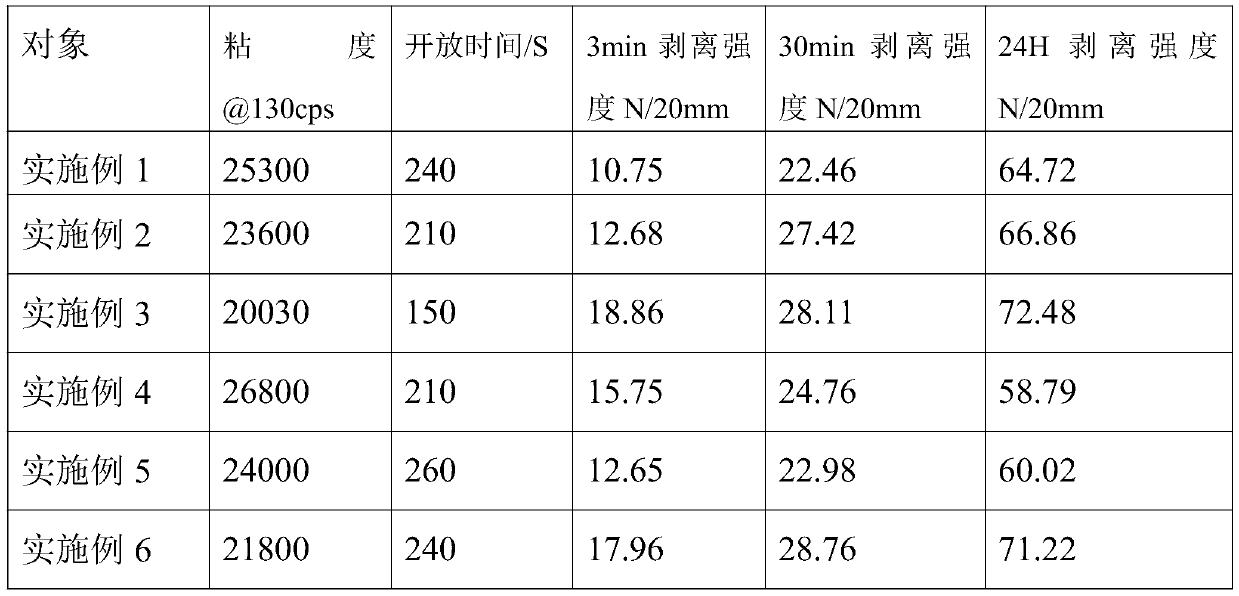

Examples

Embodiment 1

[0027] Add 300g of amorphous polyester polyol, 250g of liquid polyester polyol, 300g of polyadipate-1,4-butylene glycol ester diol, and 150g of polyurethane elastomer into the reaction equipment, heat to 120°C to start dehydration, Reduce the vacuum degree to below -0.095MPa, and test the moisture after dehydration for 2 hours. When the moisture drops below 300ppm, it is qualified; and the temperature is below 90°C, add MDI (according to the molar ratio of isocyanate NCO / OH = 1.6), and heat up to 120°C, vacuum reaction for 30min; evacuate the air in the reaction equipment with nitrogen, and add 1.5g of triethylenediamine, antioxidant 168, 1g and N-(β-aminoethyl)-γ-ammonia after returning to normal pressure 5 g of propyltrimethoxysilane was reacted for 15 minutes to obtain an adhesive.

Embodiment 2

[0029] Add 350g of amorphous polyester polyol, 300g of liquid polyester polyol, 250g of polyadipate-1,4-butylene glycol ester diol, and 100g of polyurethane elastomer into the reaction equipment, and heat to 120°C to start dehydration. The vacuum degree is reduced to below -0.095MPa, and the moisture is tested after dehydration for 2 hours. When the moisture drops below 300ppm, it is qualified; and the temperature is below 90°C, and MDI is added (according to the molar ratio of isocyanate NCO / OH=1.8), and the temperature is raised to 120°C, vacuum reaction for 30min; evacuate the air in the reaction equipment with nitrogen, and add 1.5g of pentamethyldipropylenetriamine, 1g of antioxidant 168 and 5g of anilinomethyltriethoxysilane after returning to normal pressure , and reacted for 15 minutes to obtain the adhesive.

Embodiment 3

[0031] Add 400g of amorphous polyester polyol, 250g of liquid polyester polyol, 200g of polyhexylene sebacate diol, and 150g of polyurethane elastomer into the reaction equipment, heat to 120°C to start dehydration, and the vacuum degree drops to - Below 0.095MPa, test the moisture after dehydration for 2 hours. When the moisture drops below 300ppm, it is qualified; and the temperature is below 90°C, add MDI (according to the molar ratio of isocyanate NCO / OH=2.0), heat up to 120°C, vacuum reaction 30min; evacuate the air in the reaction equipment with nitrogen, and add 1.5g of triethylenediamine, 168 of antioxidant and N-(β-aminoethyl)-γ-aminopropyltrimethoxyl group after returning to normal pressure 5 g of silane was reacted for 15 minutes to obtain an adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com