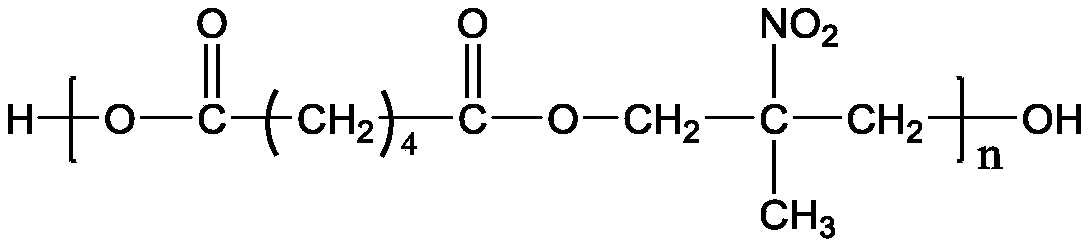

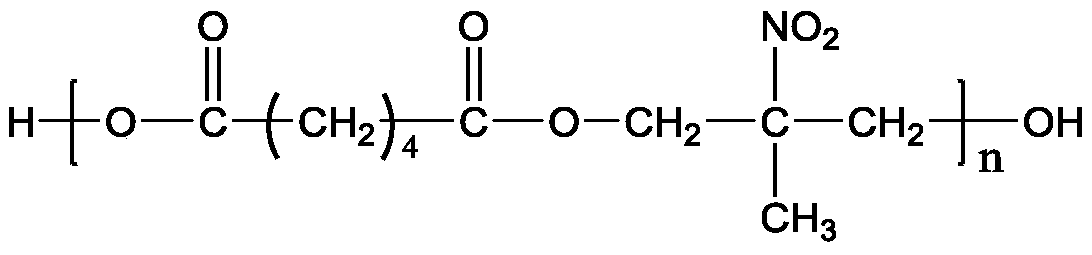

Poly (2-methyl-2-nitropropylene glycol adipate) as well as preparation method and application thereof

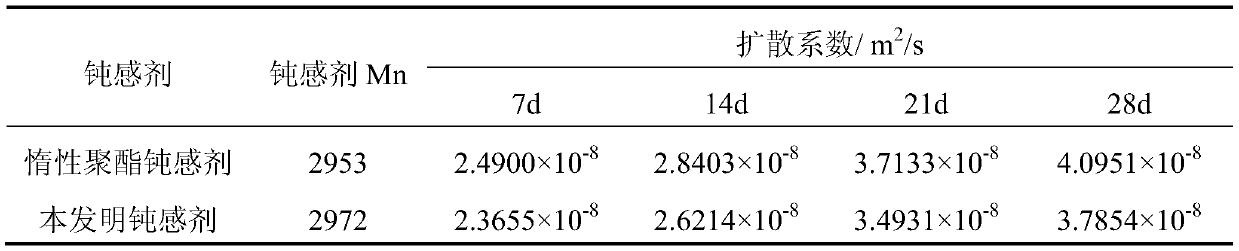

A technology of nitropropylene glycol ester and nitropropylene glycol, which is applied in the field of energetic materials, can solve the problems of low energy level and low energy level of inert polyester desensitizers, and achieve the effect of improving ballistic performance and good migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Adipic acid (146g, 1mol) and 2-methyl-2-nitropropanediol (148.5g, 1.1mol) were added to 300mL of toluene, then 3g of p-toluenesulfonic acid was added, the temperature was raised to reflux of toluene, and the ester Condensation reaction, reaction 8h. After the reaction, the temperature was lowered to below 30° C., the reaction solution was washed with water, and the toluene was evaporated under reduced pressure to obtain 274.3 g of poly-2-methyl-2-nitropropanediol adipate with a yield of 99.2%.

[0018] Structural identification: IR, ν max (cm -1 ): 2951 (-CH 2 ), 2879 (-CH 3 ), 1734 (C=O), 1549, 1352 (C-NO 2 ), 1245(C-O), 737(-(CH 2 ) 4 -).

[0019] Properties: Appearance is yellow-brown solid; number average molecular weight 2972; molecular weight distribution 1.6324.

Embodiment 2

[0021] Add adipic acid (146g, 1mol) and 2-methyl-2-nitropropanediol (135g, 1mol) into 300mL of toluene, then add 3g of p-toluenesulfonic acid, heat up to toluene reflux, and carry out esterification condensation Reaction, reaction 6h. After the reaction, the temperature was lowered to below 30° C., the reaction liquid was washed with water, and the toluene was evaporated under reduced pressure to obtain 273.4 g of poly-2-methyl-2-nitropropanediol adipate with a yield of 98.9%.

Embodiment 3

[0023] Add adipic acid (146g, 1mol) and 2-methyl-2-nitropropanediol (121.5g, 0.9mol) into 300mL of toluene, then add 3g of p-toluenesulfonic acid, heat up to toluene reflux, and carry out esterification Condensation reaction, reaction 5h. After the reaction, the temperature was lowered to below 30° C., the reaction solution was washed with water, and the toluene was evaporated under reduced pressure to obtain 271.9 g of poly-2-methyl-2-nitropropanediol adipate with a yield of 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diffusion coefficient | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com