Preparation method of side-chain hydrophilic polyester fabric moisture absorption and sweat releasing finishing agent and the finishing agent

A polyester fabric, moisture wicking technology, applied in the direction of fiber treatment, fiber type, textile and paper making, etc., can solve the problem that the finishing agent cannot take into account the hydrophilic and washable at the same time, and achieve excellent hydrophilic performance and washable performance, Solve the effect of poor water solubility and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Synthesis of side chain hydrophilic diols: first add 37g glycidyl alcohol and 500g monomethyl-terminated ethylene glycol (molecular weight is 1000), add 179g ethanol, keep warm at 60°C for 5 hours, change to reduced pressure distillation after the reaction ends, and distill Remove ethanol to get side chain hydrophilic diol.

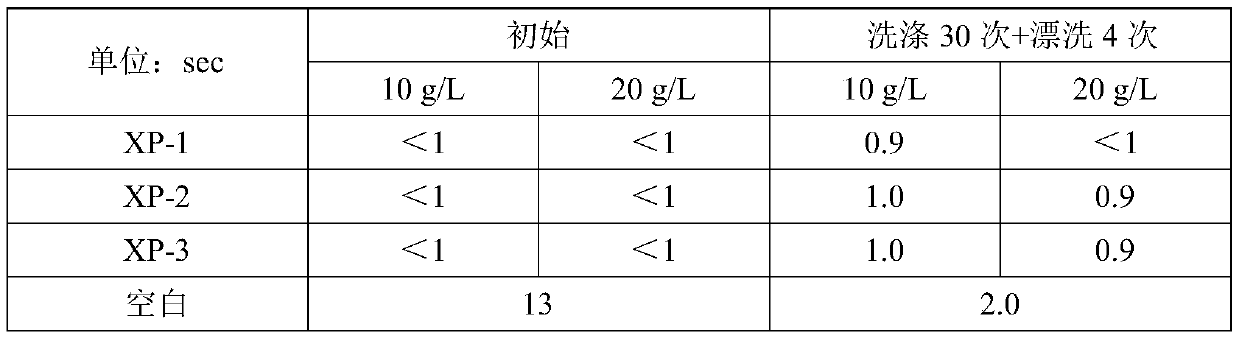

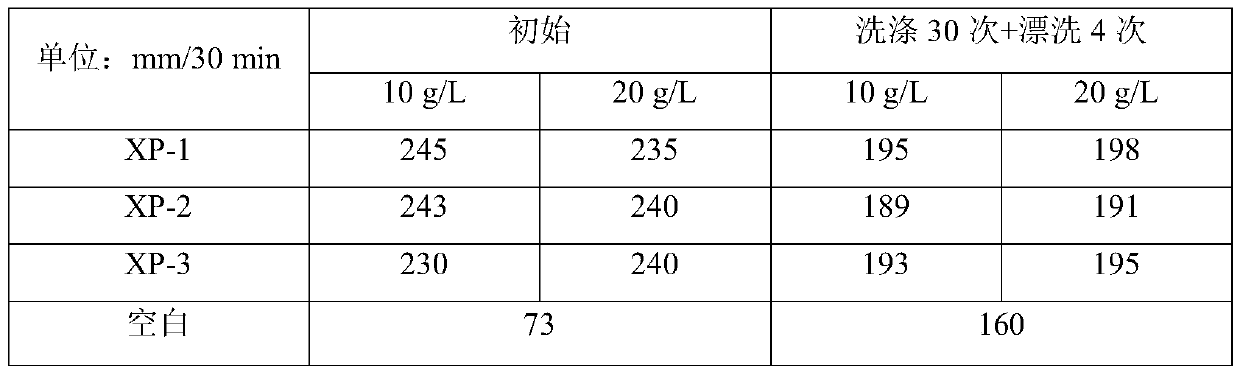

[0022] Synthesis of side-chain hydrophilic moisture-absorbing and sweat-wicking agent: first, dehydration reaction is carried out on polyethylene glycol and side-chain hydrophilic diol, and the temperature is controlled at 100-105° C. for vacuum dehydration for 1 hour. After the dehydration is completed, 40g dimethyl terephthalate, 150g polyethylene glycol, 30g ethylene glycol, 40g side chain hydrophilic glycol, and 0.06g zinc acetate are added to the reaction vessel equipped with a thermometer and a nitrogen tube in sequence, Slowly raise the temperature under the protection of nitrogen, and when the temperature rises to 170°C in 25-30 minutes, co...

Embodiment 2

[0026] Synthesis of side-chain hydrophilic diols: first add 37g glycidyl alcohol and 500g monomethyl-terminated ethylene glycol (the number average molecular weight is 1000), add 179g ethanol, keep warm at 60°C for 5 hours, and change to vacuum distillation after the reaction , Ethanol is evaporated to obtain a side chain hydrophilic diol.

[0027] Synthesis of side-chain hydrophilic moisture-absorbing and sweat-wicking agent: first, dehydration reaction is carried out on polyethylene glycol and side-chain hydrophilic diol, and the temperature is controlled at 100-105° C. for vacuum dehydration for 1 hour. After the dehydration is completed, 38g dimethyl terephthalate, 160g polyethylene glycol, 28g ethylene glycol, 50g side chain hydrophilic glycol, and 0.08g calcium acetate are added to the reaction vessel equipped with a thermometer and a nitrogen tube in sequence, Slowly raise the temperature under the protection of nitrogen, and when the temperature rises to 170°C in 25-30...

Embodiment 3

[0031] Synthesis of side chain hydrophilic diols: first add 37g glycidyl alcohol and 500g monomethyl-terminated ethylene glycol (molecular weight is 1000), add 179g ethanol, keep warm at 60°C for 5 hours, change to reduced pressure distillation after the reaction ends, and distill Remove ethanol to get side chain hydrophilic diol.

[0032] Synthesis of side-chain hydrophilic moisture-absorbing and sweat-wicking agent: first, dehydration reaction is carried out on polyethylene glycol and side-chain hydrophilic diol, and the temperature is controlled at 100-105° C. for vacuum dehydration for 1 hour. After the dehydration is completed, 30g dimethyl terephthalate, 140g polyethylene glycol, 24g ethylene glycol, 42g side chain hydrophilic glycol, and 0.07g magnesium acetate are added to the reaction vessel equipped with a thermometer and a nitrogen tube in sequence. Slowly raise the temperature under the protection of nitrogen, and when the temperature rises to 170°C in 25-30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com