Water-soluble hyperbranched thick oil viscosity-reducing oil-displacing agent and preparation method thereof

A viscous oil-displacing agent and water-soluble technology, applied in the field of water-soluble hyperbranched heavy oil viscosity-reducing oil-reducing agent and its preparation, can solve the problem of low water-flooding recovery rate, complicated synthesis steps, polymer heavy oil viscosity-reducing agent problems such as poor solubility, to achieve the effect of expanding the swept volume, simple synthesis steps, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

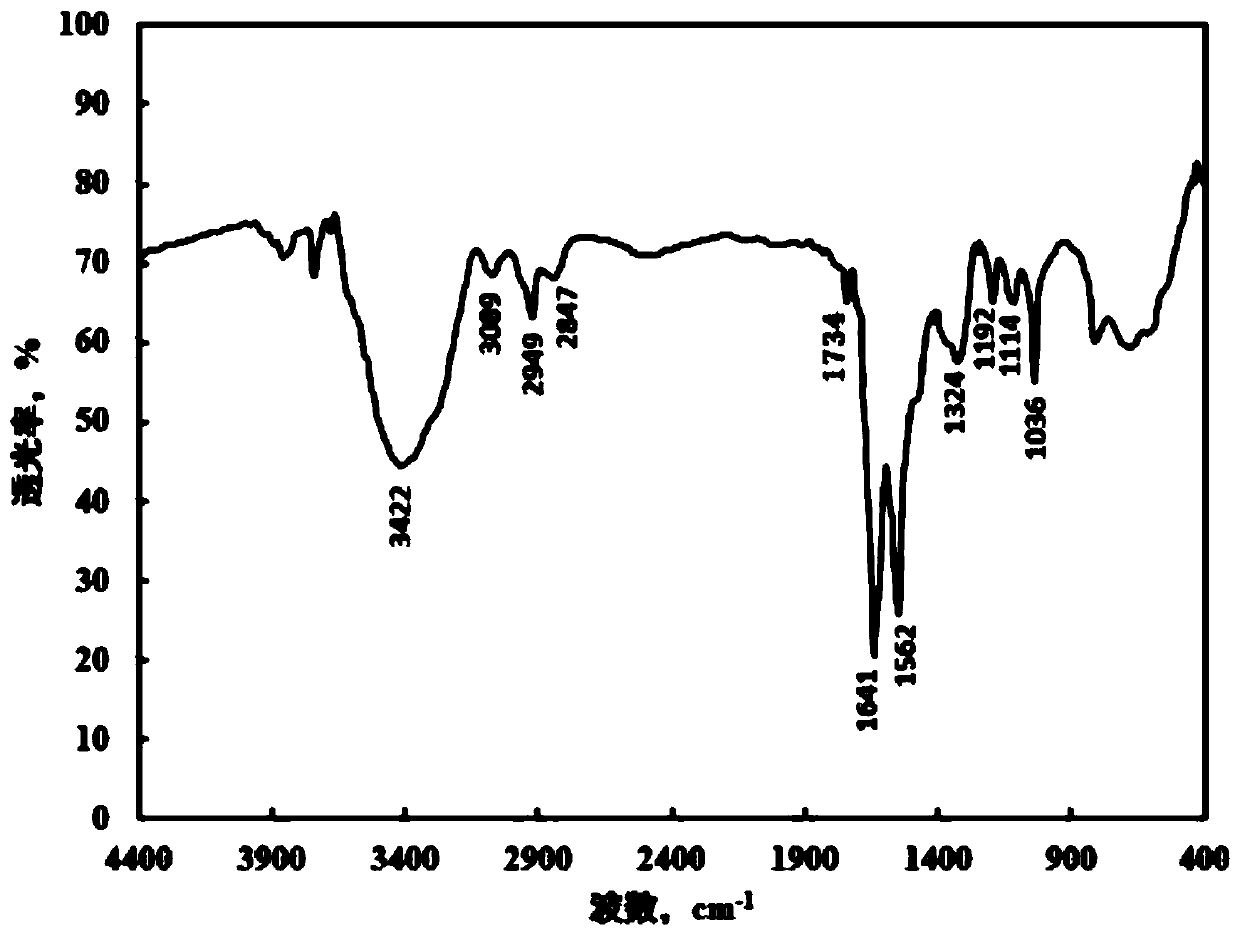

[0028] A preparation method of a water-soluble hyperbranched heavy oil viscosity reducing oil displacement agent, the steps are as follows:

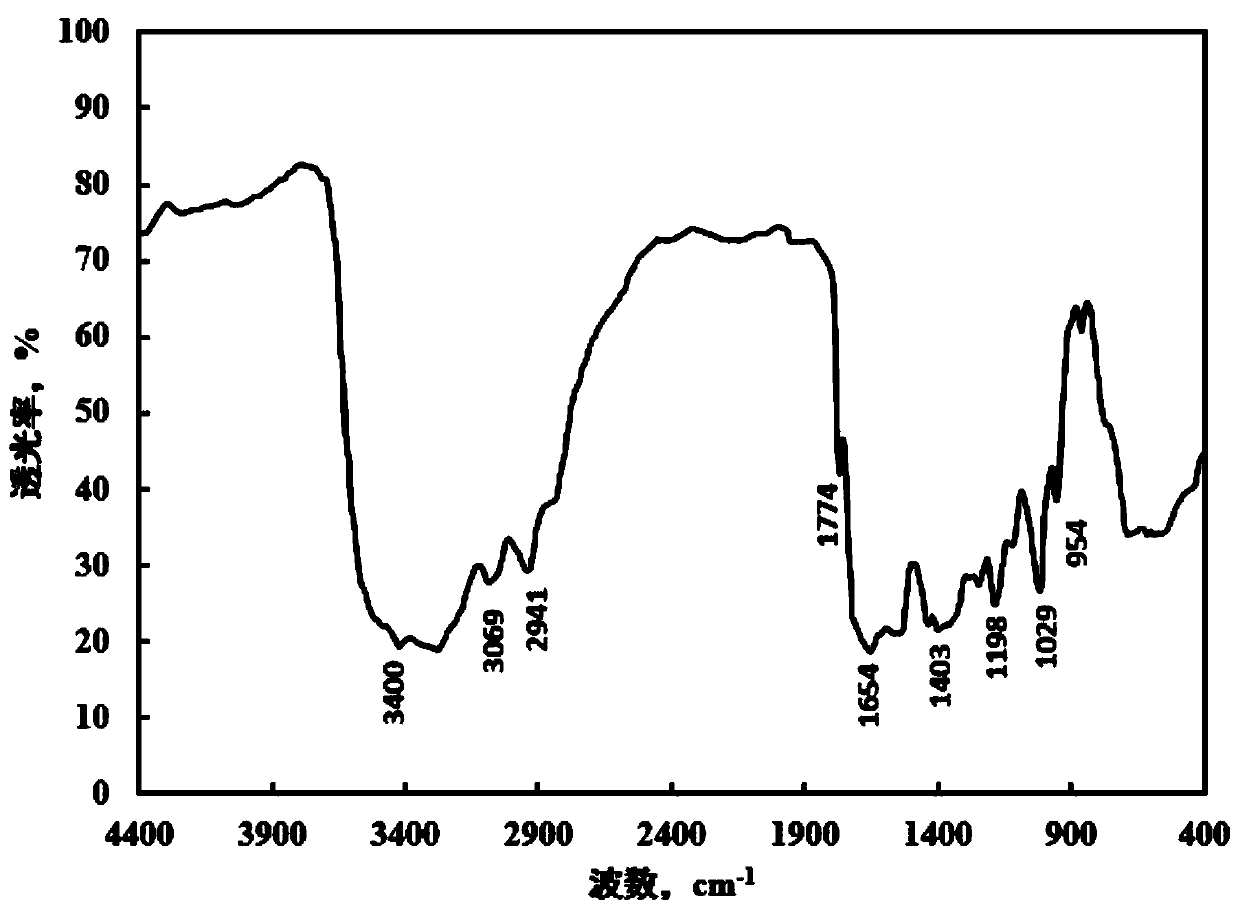

[0029] S1. Functional modification of backbone monomer 2.0 generation polyamide-amine

[0030]Dissolve 8.00g of 2.0-generation polyamidoamine monomer and 4.38g of maleic anhydride in 30g of N,N-dimethylformamide solution in sequence, and place the system in an ice-water bath (below 10°C) In the process, nitrogen protection was carried out for 40 minutes at the same time, and the stirring condition was completely dissolved; the reaction was carried out at room temperature and protected from light for 7 to 8 hours, and a brown transparent solution of the functionalized skeleton monomer after modification was obtained; the solution was added to an equal volume of chloroform solution. , a light yellow powdery substance can be precipitated, which is a relatively pure functionalized backbone monomer modified polyamide-amine. Reaction equation...

Embodiment 2

[0042] A preparation method of a water-soluble hyperbranched heavy oil viscosity reducing oil displacement agent, the steps are as follows:

[0043] Steps S1 and S2 are the same as in Embodiment 1.

[0044] S3. Put a certain amount of deionized water in the reaction vessel, and add 0.29% by mass of the 2.0th generation functionalized backbone monomer polyamide-amine, 16.82% Acrylamide, 17.05% acrylic acid, 44.05% octylphenol polyoxyethylene ether maleate (n is 20) and 21.79% 2-acrylamido sodium tetradecylsulfonate monomer (monomer The total amount is 100%), mixed and stirred evenly, and prepared into a reaction solution with a total mass percentage concentration of five monomers of 25%, and then vacuumized for 10 minutes to remove dissolved gas in the solution.

[0045] S4, adding sodium carbonate to the reaction solution to adjust the pH value of the solution to 8.0, then in a water bath at 50°C and at a stirring rate of 250r / min, protect with inert gas nitrogen for 60min; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com