High-density nanometer material vapor preparation method

A nano-material and high-density technology, which is applied in the field of gas-phase preparation of high-density nano-materials, can solve the problems of difficulty in synthesizing high-density nano-materials, high heat source energy, and increased costs, and achieves adjustable particle size, low heat source energy, and equipment mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

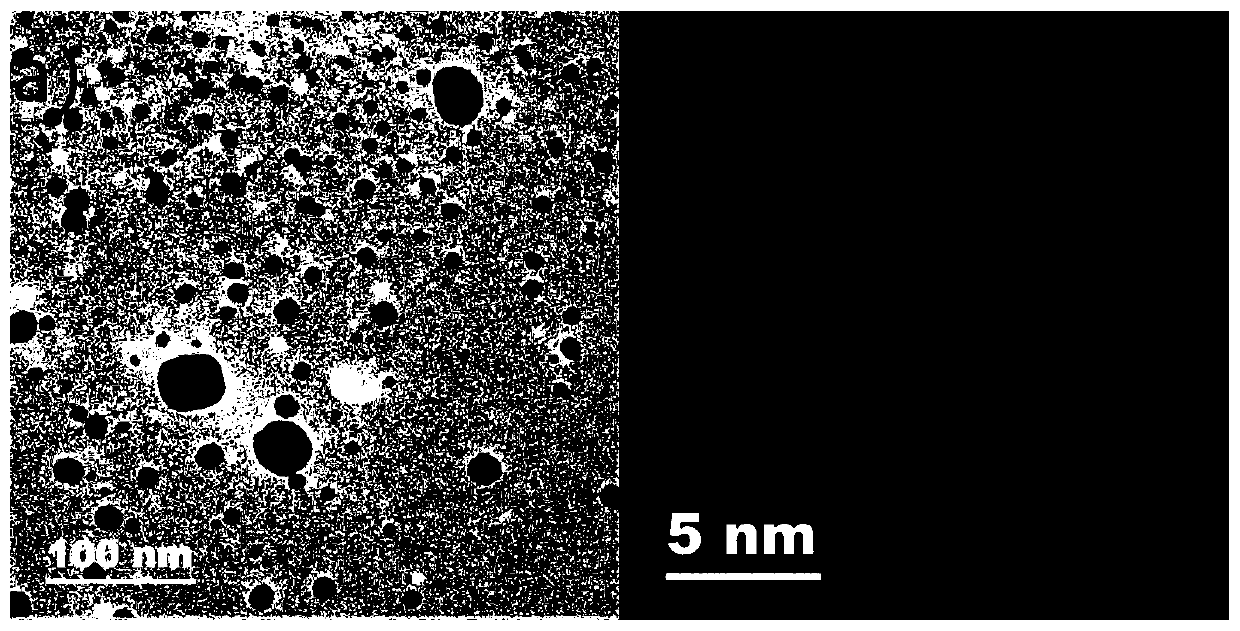

[0028] The specific preparation method can be realized through the following steps:

[0029] (1) Under vacuum conditions, the substrate in the chamber is cooled, and the raw materials in the state of atoms, molecules or nanoparticles are deposited on the substrate while passing inert gas or reactive gas into the chamber. Raw materials in the state of molecules or nanoparticles are mixed and solidified together on the substrate to form a mixed target; in order to freeze gaseous molecules, it is necessary to ensure that the cooling temperature of the substrate is lower than the freezing point of the gaseous molecules. specifically is:

[0030] (1.1) Under vacuum conditions, the substrate in the chamber is cooled to below the freezing point of gas molecules;

[0031] (1.2) Pass inert gas or reactive gas into the chamber, so that the gas molecules passed in are mixed with the raw materials in the state of atoms, molecules or nanoparticles in the chamber and solidified together on...

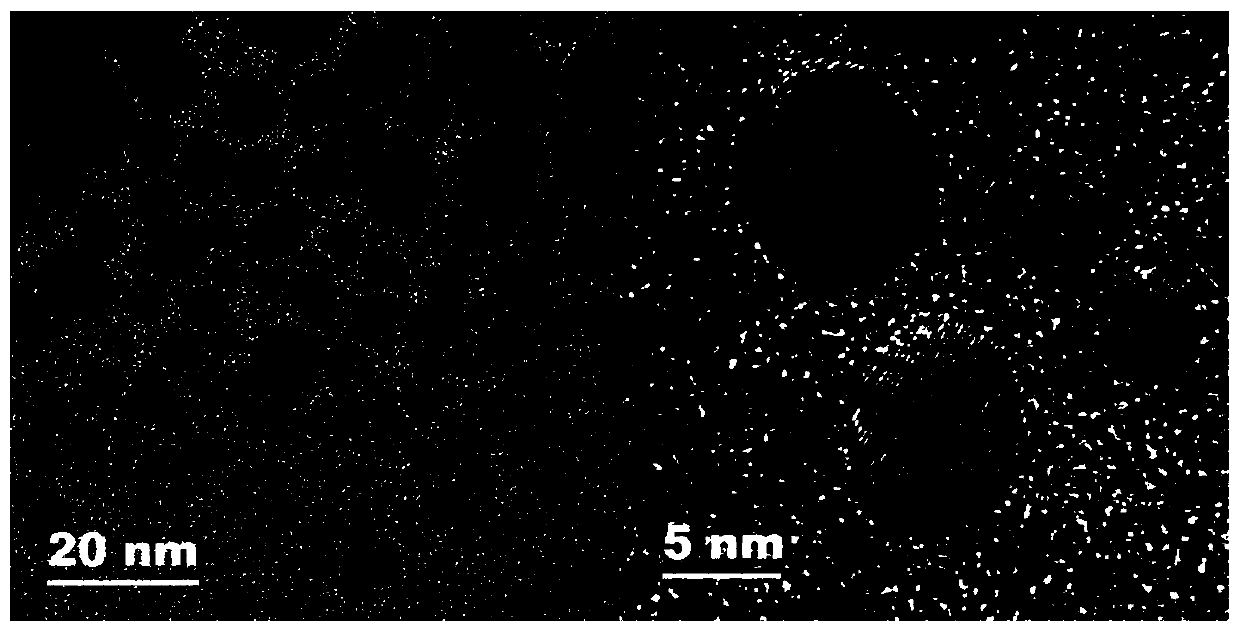

Embodiment 1

[0042] Now take the preparation of high-density gas-phase Ag nanomaterials as an example, the specific method is as follows:

[0043] (1) Use a molecular pump to pump the vacuum chamber to 1*10 -5 Below Pa, the temperature of the oxygen-free copper substrate is cooled to 170K by passing through liquid nitrogen; at the same time, the electron beam evaporation source and the CO 2 Mass flowmeter, the evaporation material of the electron beam evaporation source is high-purity Ag (99.99%), the emission current is adjusted to 300nA, the mass flowmeter CO 2 The gas flow rate was adjusted to 12 sccm, the deposition time was set to 15 minutes, and the CO 2 Gas molecules mix with Ag in atomic or nanoparticle state and co-solidify on the substrate to form Ag-CO 2 Mixed targets.

[0044] (2) After the deposition is completed, turn off the electron beam evaporation source and the mass flow meter at the same time, turn on the laser generator, adjust the laser optical path and focus on th...

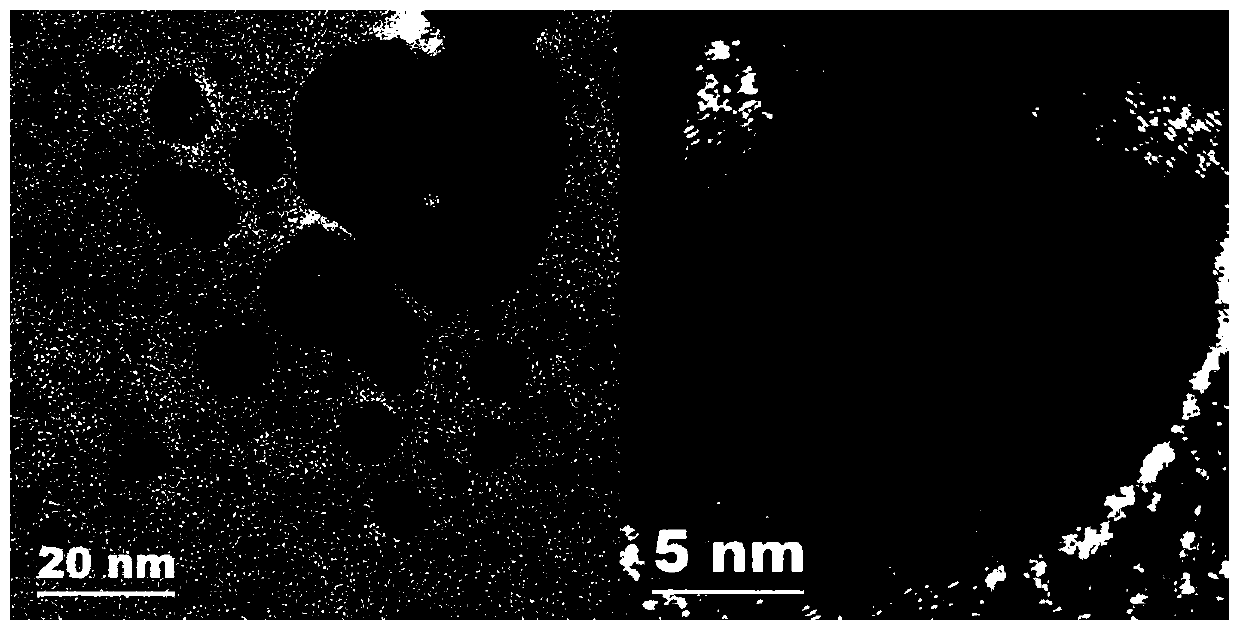

Embodiment 2

[0048] Taking the preparation of high-density gas-phase Ag nanomaterials as an example, the specific method is as follows:

[0049] (1) The molecular pump pumps the vacuum chamber to 1*10 -5 Below Pa, the temperature of the oxygen-free copper substrate is cooled to 130K by passing through liquid nitrogen, and at the same time, the electron beam evaporation source and the CO 2 Mass flowmeter, the evaporation material of the electron beam evaporation source is high-purity Ag (99.99%), the emission current is adjusted to 300nA, the mass flowmeter CO 2 The gas flow rate was adjusted to 8 sccm, the deposition time was set to 15 minutes, and the CO 2 Gas molecules mix with Ag in atomic or nanoparticle state and co-solidify on the substrate to form Ag-CO 2 Mixed targets.

[0050] (2) After the deposition is completed, turn off the electron beam evaporation source and the mass flow meter at the same time, turn on the laser generator, adjust the laser optical path and focus on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com