Mold shell fire-resistant coating material for investment casting precision castings

A precision casting and refractory coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of high product defect rate, long residence time, poor mold filling, etc., and achieve good surface quality, Extended service life and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

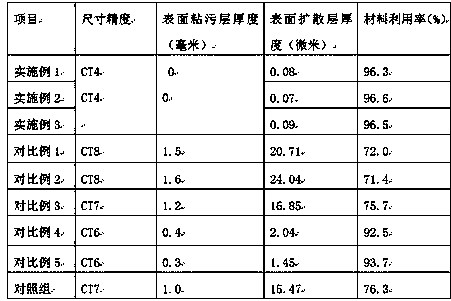

Examples

Embodiment 1

[0019] A shell refractory coating material for investment casting precision castings, prepared by dispersing the prepared powdery refractory material into a liquid binder with a powder-to-liquid ratio of 2.2 g / ml, and adding other auxiliary materials after the dispersion is uniform to prepare the coating Layer material, described refractory material preparation method comprises the following steps:

[0020] (1) Weigh 10 grams of tetraethyl orthosilicate and place it in a beaker, add 55 milliliters of absolute ethanol, stir evenly, add ammonia solution dropwise to adjust the pH value of the system between 10.3-10.5, transfer it to a volumetric flask, and use Dilute to the volume with deionized water to obtain 100 ml of solution, place it in a 55°C oven for 24 hours to form a gel;

[0021] (2) Weigh 18 grams of magnesium chloride and place it in a beaker, add 80 milliliters of deionized water, stir to dissolve, transfer the gel prepared in step (1) to an aqueous magnesium chlori...

Embodiment 2

[0030] A shell refractory coating material for investment casting precision castings, prepared by dispersing the prepared powdery refractory material into a liquid binder with a powder-to-liquid ratio of 2.25 g / ml, and then adding other auxiliary materials to prepare the coating material Layer material, described refractory material preparation method comprises the following steps:

[0031] (1) Weigh 11 grams of tetraethyl orthosilicate and place it in a beaker, add 57 milliliters of absolute ethanol, stir well, add ammonia solution dropwise to adjust the pH value of the system between 10.3-10.5, transfer it to a volumetric flask, and use Dilute with deionized water to obtain 100 ml of solution, place it in an oven at 58°C for aging for 27 hours, and form a gel;

[0032] (2) Weigh 19 grams of magnesium chloride and place it in a beaker, add 85 milliliters of deionized water, stir to dissolve, transfer the gel prepared in step (1) to an aqueous solution of magnesium chloride, a...

Embodiment 3

[0041] A shell refractory coating material for investment casting precision castings, prepared by dispersing the prepared powdery refractory material into a liquid binder with a powder-to-liquid ratio of 2.3 g / ml, and adding other auxiliary materials after the dispersion is uniform. Layer material, described refractory material preparation method comprises the following steps:

[0042] (1) Weigh 12 grams of tetraethyl orthosilicate and place it in a beaker, add 60 milliliters of absolute ethanol, stir evenly, add ammonia solution dropwise to adjust the pH value of the system between 10.3-10.5, transfer it to a volumetric flask, and use Dilute with deionized water to obtain 100 ml of solution, and place it in an oven at 60°C for 30 hours to age to form a gel;

[0043] (2) Weigh 20 grams of magnesium chloride and place it in a beaker, add 90 milliliters of deionized water, stir to dissolve, transfer the gel prepared in step (1) to an aqueous magnesium chloride solution, add 12 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com