A nitrogen-doped porous nanosheet silicon-carbon composite material and its preparation method and application

A technology of silicon-carbon composite materials and nanosheets, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as capacity fading, failure to fundamentally suppress charge and discharge volume effects, and easy aggregation of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of nitrogen-doped porous nano-sheet silicon-carbon composite material: add soluble organic matter as carbon source in a closed container, then add ammonium chloride, and finally add silicon dioxide to stir and disperse, and perform hydrothermal reaction at 100-250°C for 2- After 24 hours, the precursor was obtained by drying, and an appropriate amount of magnesium powder was added to the precursor to be calcined and reduced at 650-750°C, and finally washed and etched with hydrofluoric acid to obtain a nitrogen-doped porous nanosheet silicon-carbon composite material.

[0029] The preparation method of described silica is as follows:

[0030] Mix absolute ethanol, water, and ammonia water, stir at 25°C for 30 minutes, quickly add tetraethyl orthosilicate, continue stirring, centrifuge, wash with water, wash with alcohol, and dry to obtain silica nanospheres with a particle size of 200-300nm.

[0031] The preferred temperature of the above-mentioned h...

Embodiment 1

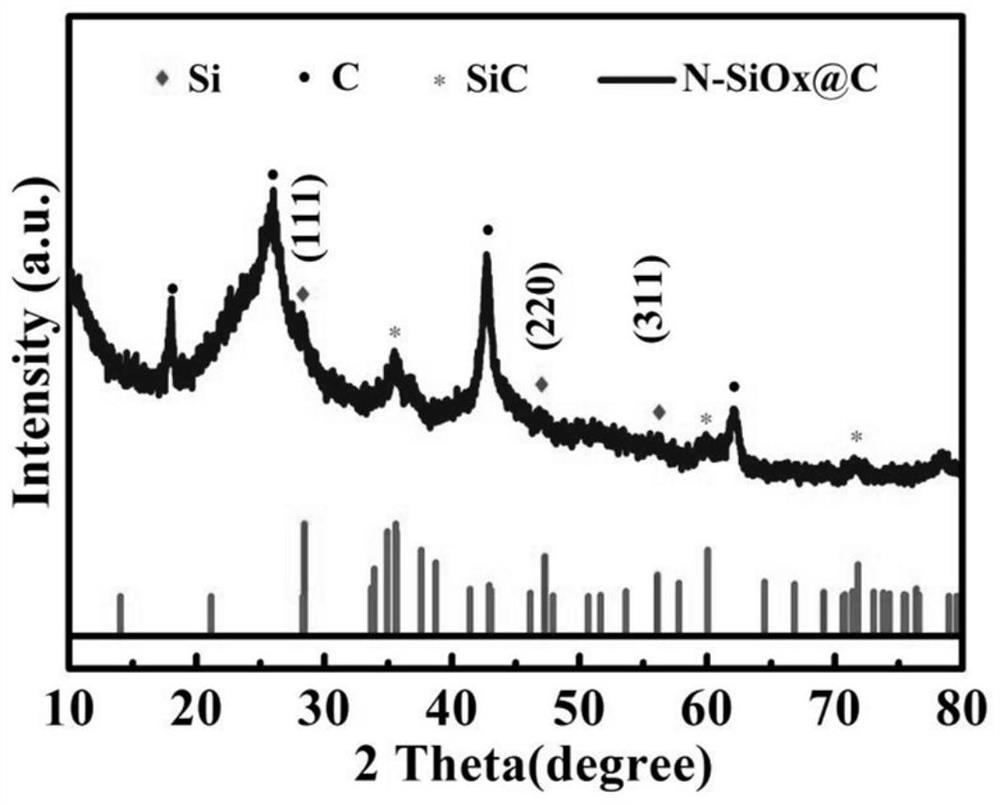

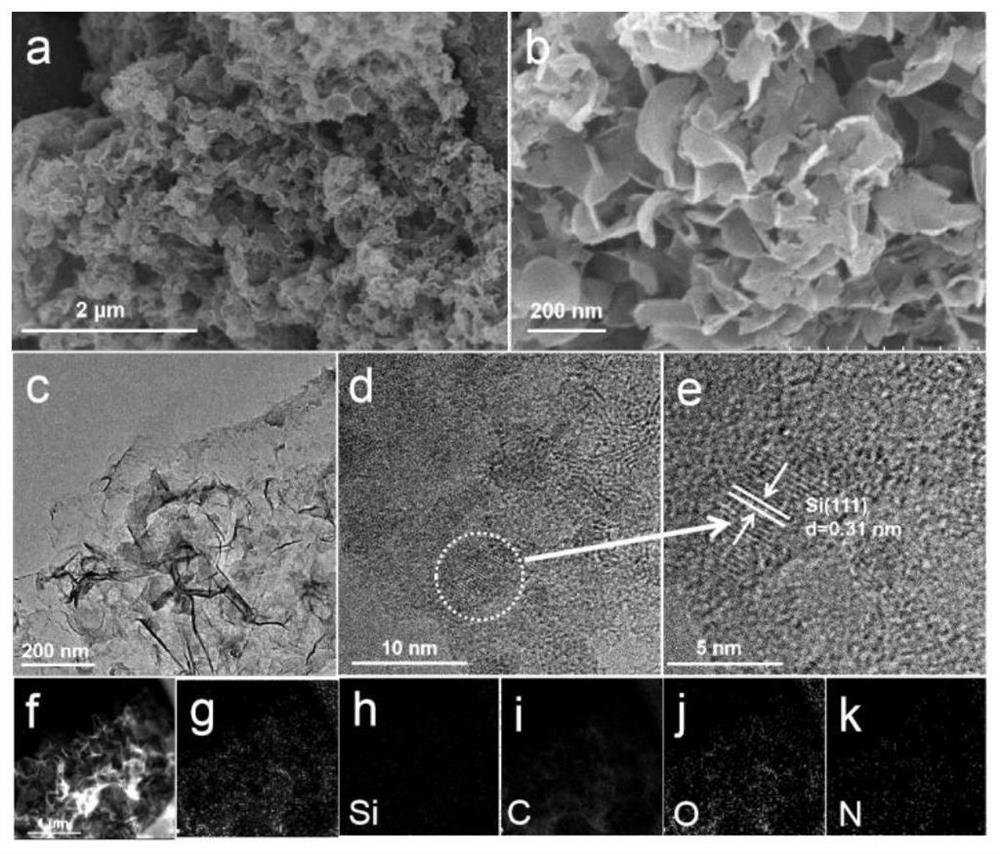

[0041] Dissolve 5g of glucose and 5g of ammonium chloride in 70ml of water, then stir thoroughly with 1g of silicon dioxide, transfer the mixture to a closed reaction kettle, and react at 220°C for 3.5h. After the reaction is completed, the precursor is obtained by drying. Add magnesium powder, the mass of which is 1 times the mass of the precursor, grind evenly, and calcinate at 650°C for 10h under an argon atmosphere, then stir in 1M HCl for 2 hours to remove impurities, wash, filter and dry with a mass fraction of 2%. HF etching for 6h, washing and drying to obtain a silicon-carbon composite material, the powder diffraction pattern is shown in figure 1 , as seen from the powder diffraction pattern, the three peaks at 28.6, 47.4, and 56.3 degrees correspond to (111), (200), (311) crystal planes of cubic Si (JCPDS 27-1402). At 35.6, 60.0, 71.8, the corresponding peaks are SiC peaks, and the peaks at 18.0, 26.9, 42.8, 62.1 degrees correspond to C peaks. figure 2 In a, b and...

Embodiment 2

[0045] 5.5g of sucrose and 4.5g of ammonium chloride were dissolved in 70ml of water, then 1.2g of silicon dioxide was stirred thoroughly, the mixture was transferred to a closed reaction kettle, and reacted at 200°C for 4h. After the reaction is completed, the precursor is obtained by drying. Add magnesium powder, the mass of which is 1.5 times the mass of the precursor, grind evenly, and calcinate at 690°C for 6h under an argon atmosphere, then stir in 1M HCl for 2 hours to remove impurities, wash, filter and dry with a mass fraction of 0.5% HF etching for 10 hours, washing and drying to obtain a silicon-carbon composite material to obtain a silicon-carbon composite material.

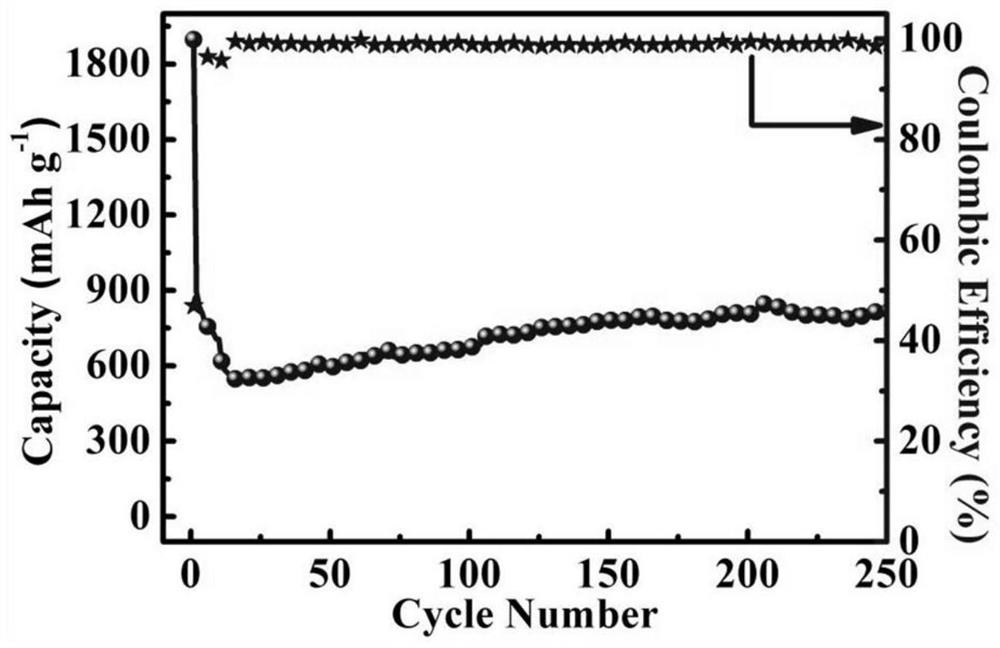

[0046] Mix the obtained silicon-carbon composite material with acetylene black and polyvinylidene fluoride in a mass ratio of 8:1:1, and smear it on a copper foil to assemble a button battery as the negative electrode material of a lithium-ion battery. The electrolyte is LiPF 6 (1mol / L):EC:DMC=1:1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com