Preparation method of carbon composite silicon anode material of lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in the field of materials, can solve problems such as poor safety, high cost, and low efficiency, and achieve the effects of buffering volume expansion, enhancing conductivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

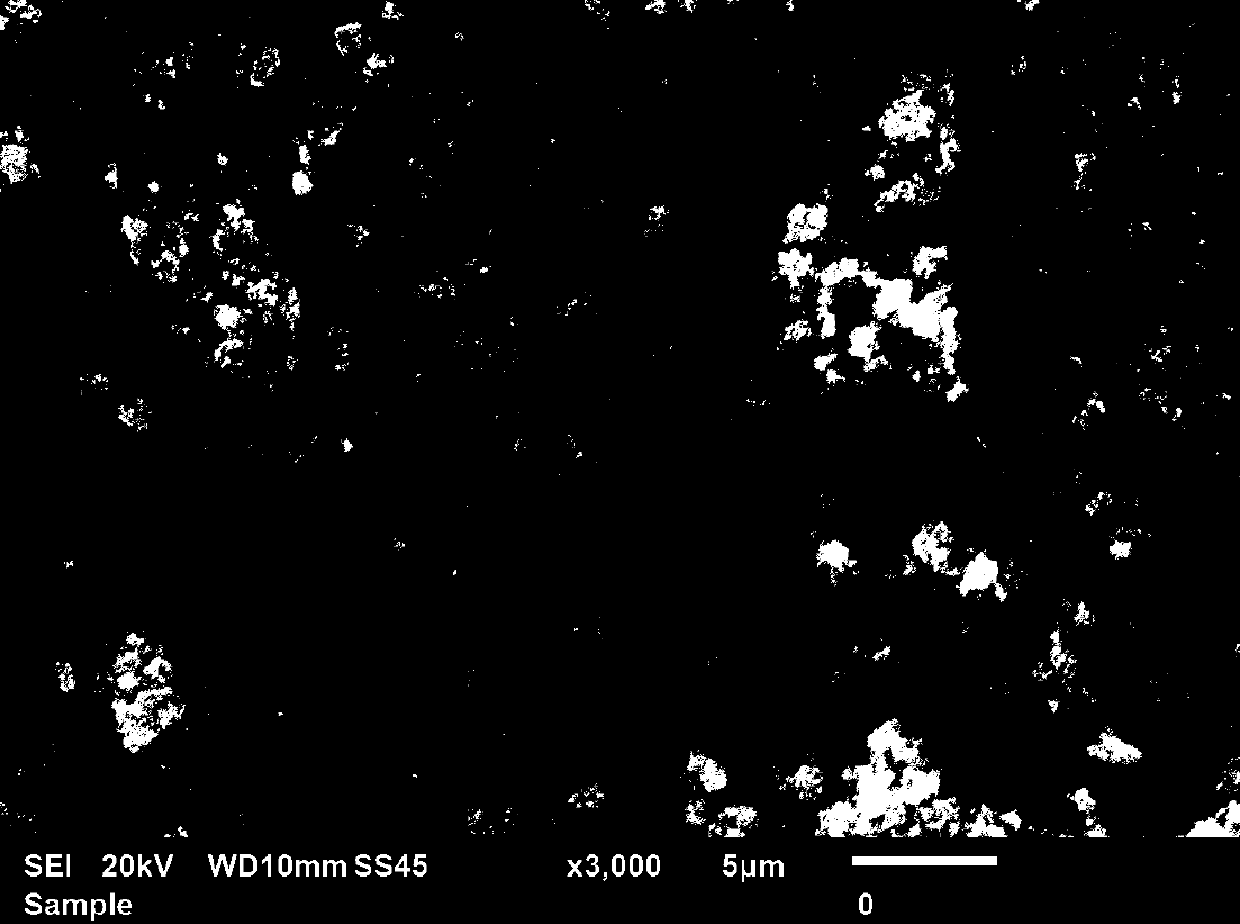

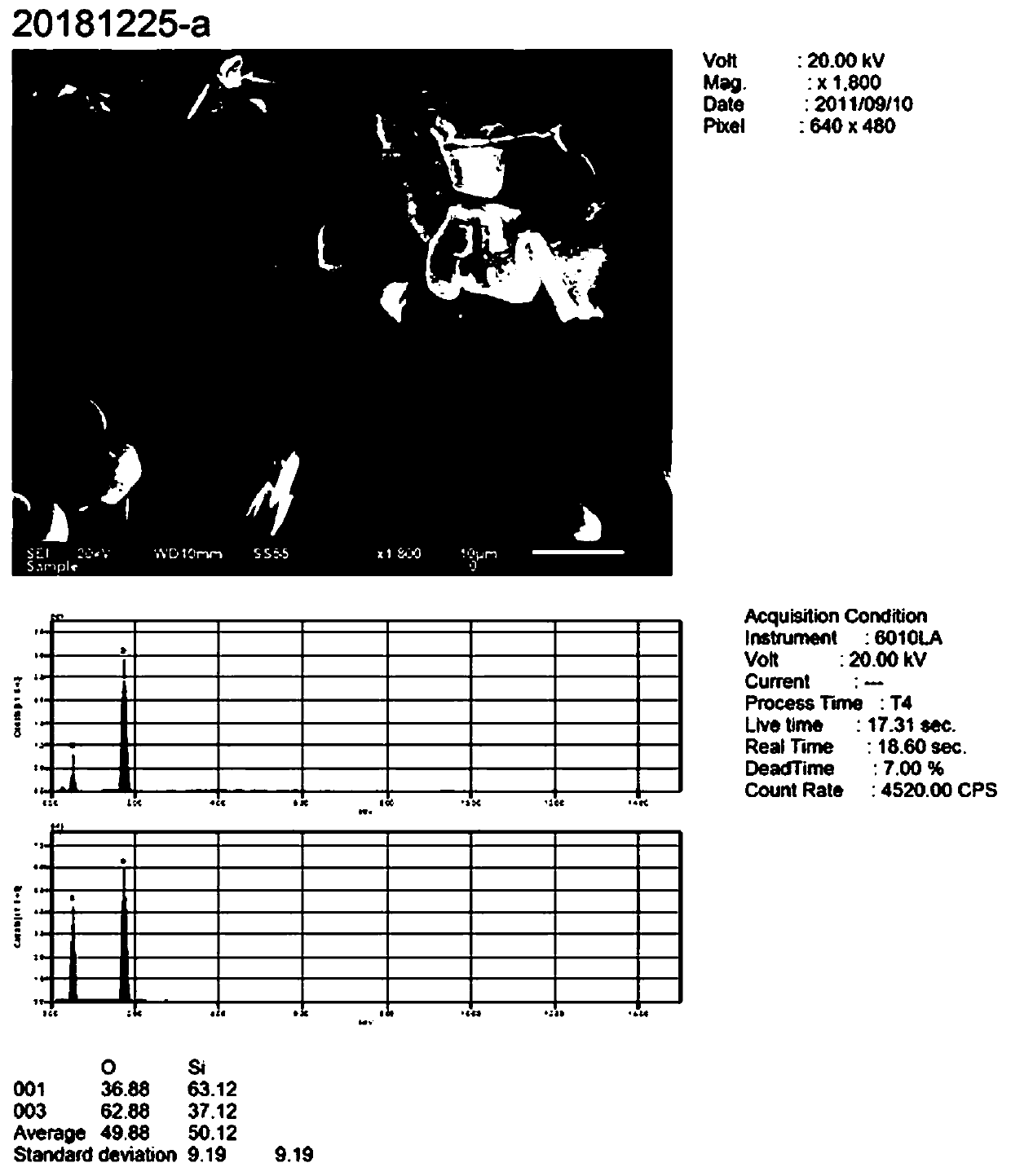

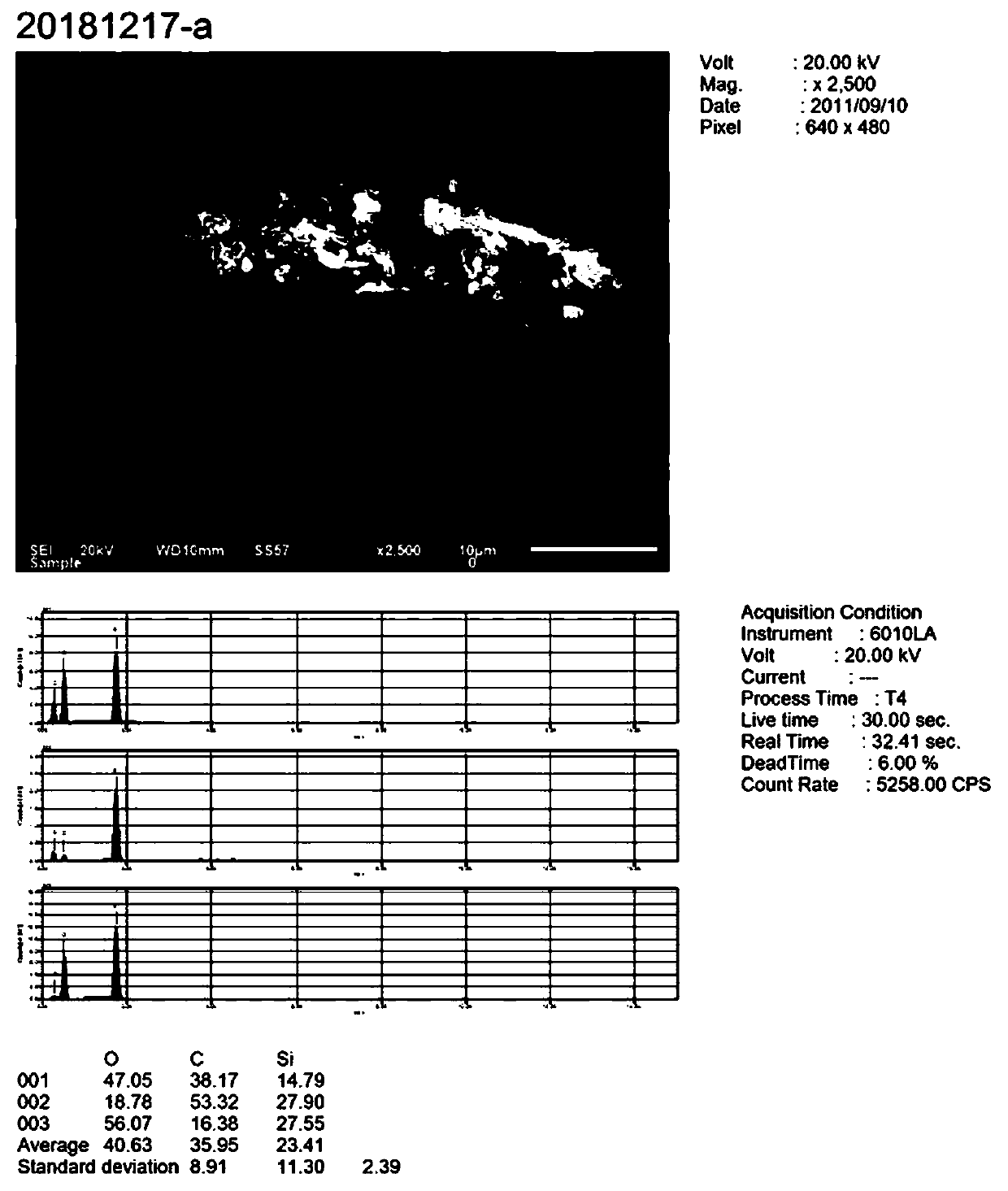

[0030] Put 50 grams of fumed silica (attached figure 1 , it can be seen that fumed silica is the aggregate of nano-silica, the average particle size of nano-silica is 20-30nm) is placed at the bottom of the container, and then 500 grams of NaCl and 100 grams of organic carbon source glucose are evenly mixed and loaded , heated to above 900°C to form a high-temperature molten salt mixture; glucose is cracked into atomic carbon in the molten salt, the atomic carbon dissolves and diffuses, and reduces the white carbon black floating in the melt; part of the white carbon black is reduced to form silicon, and part of the white carbon black Carbon black is reduced to oxygen-changed silicon oxide, some carbon atoms are supersaturated and precipitated to form carbon black and graphene, and part of the silicon dioxide is not reduced, gradually forming micro-nano carbon and silicon-oxygen-changed silicon oxide-silicon oxide (micro-nono-Si / SiOx / SiO 2 @C) compound; the compound increases...

Embodiment 2

[0032] A square flat-bottomed container is placed in the vacuum chamber, and the tank is filled with Bi / In alloy (Bi:In=21.5:78.5, at; at this time, the melting point of the alloy is only 72°C), and the alloy is heated to 1200°C to form a melt; adopt vertical transmission The screw transports the silica separated by the partition to the bottom of the container and spreads the silica at the bottom by using a horizontal conveying screw; the carbon source pressurized methane is passed into the alloy melt through a circular tube, and the carbon source and silica are metered Ratio 4:1 (wt). At this high temperature, methane cracks into atomic carbon, atomic carbon dissolves and reduces the floating silica in the melt; part of silica is reduced to silicon, part of silica is reduced to oxygen-changed silicon oxide, and part of atomic Carbon is supersaturated and precipitated to form carbon black and graphene, and part of the silicon dioxide is not reduced; thereby obtaining micro-nan...

Embodiment 3

[0034] A nickel cylindrical container is filled with NaCl / KCl mixed salt (NaCl:KCl=1:1, wt;), and heated to above 700°C to form a molten salt; the quartz sand and the organic carbon source bisphenol A are evenly mixed and stacked on the The surface of the molten salt, and use the vertical conveying screw to transport the quartz sand and bisphenol A to the middle and lower part of the container while stirring to make them evenly dispersed in the melt; due to the catalytic effect of Ni, bisphenol A is completely cracked at this temperature, cracked into Atomic carbon and atomic carbon dissolve and reduce the sinking quartz sand in the melt; part of the quartz sand is reduced to form silicon, part of the quartz sand is reduced to oxygen-variable silicon oxide, and part of the atomic carbon is supersaturated and precipitated to form carbon black and graphene , part of the quartz sand has not been reduced; thereby obtaining micro-nano carbon and silicon-oxygenated silicon oxide-sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com