Treatment method and treatment system for spent electroless nickel solution

A treatment system and treatment method technology, applied in the field of purification and treatment of chemical nickel waste liquid, can solve the problems of harsh reaction conditions, poor treatment effect of chemical nickel waste mother liquid, high disposal cost and economic pressure on enterprises, and achieve the effect of mild treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

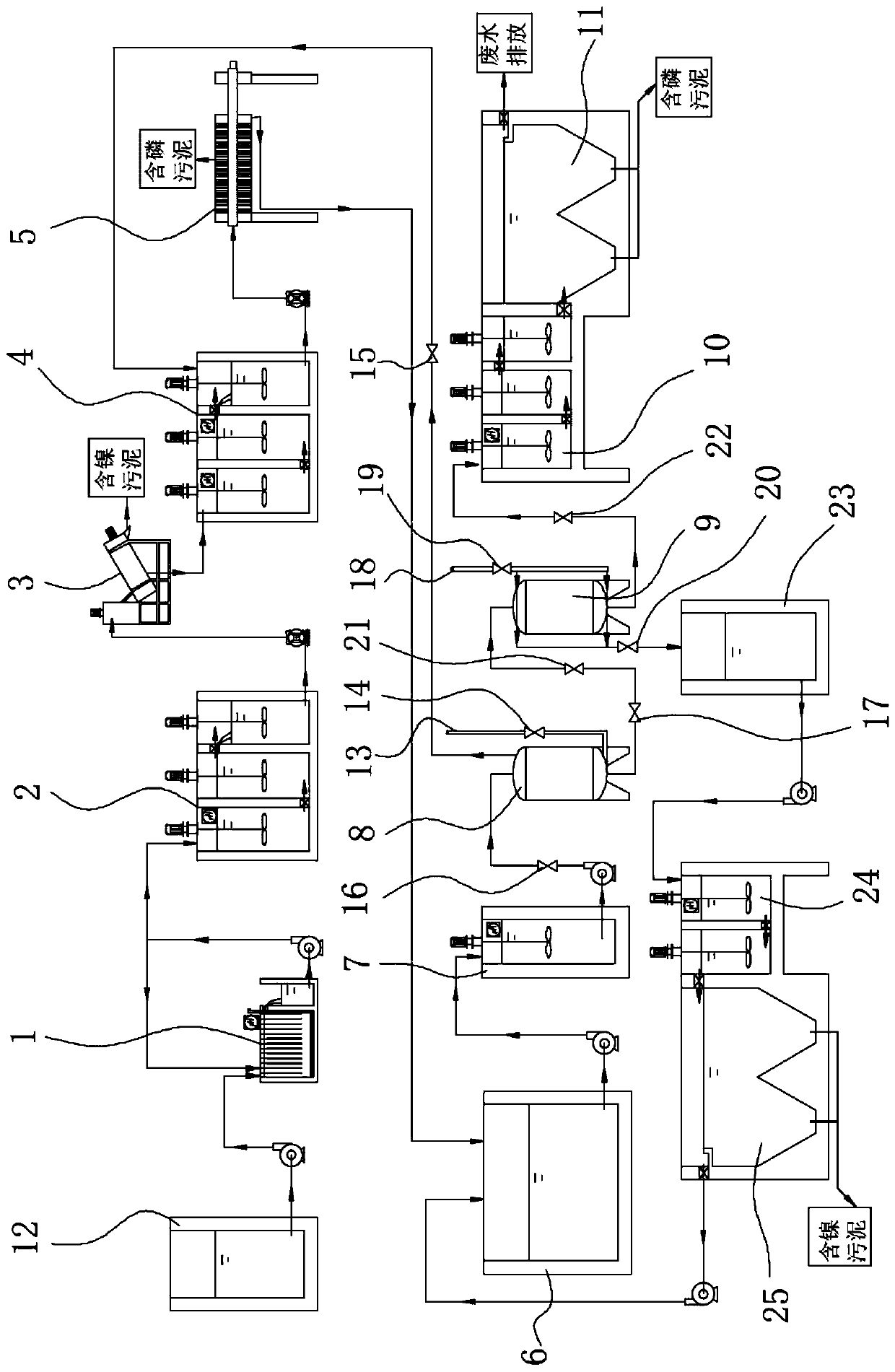

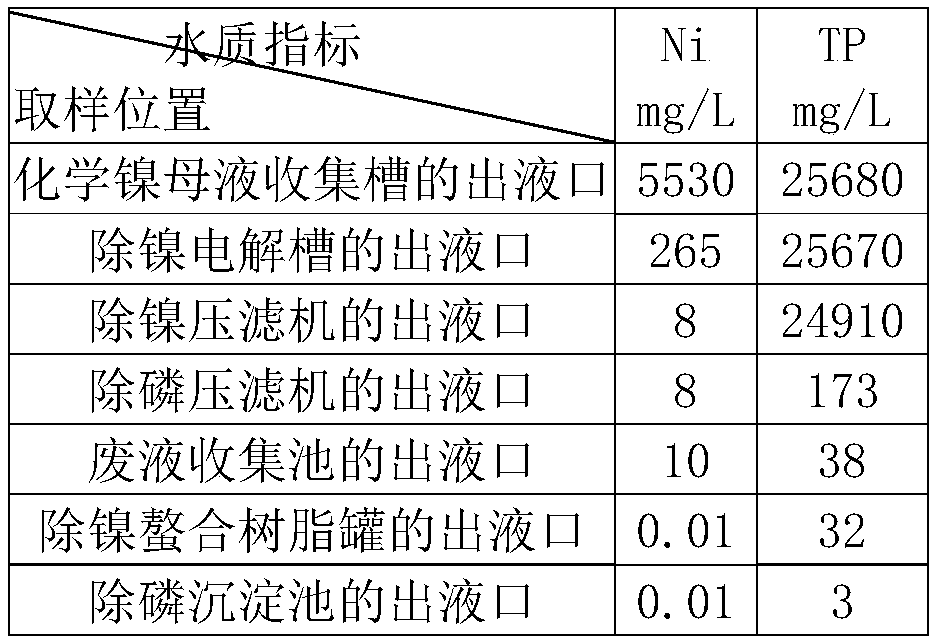

[0043] Such as figure 1 As shown, a treatment system for chemical nickel wastewater includes sequentially connected waste mother liquor pretreatment devices and mixed waste liquid purification devices. The waste mother liquor pretreatment device includes sequentially connected nickel removal electrolytic cells 1, nickel removal reaction precipitation tank 2, nickel removal filter press 3, phosphorus removal reaction precipitation tank 4 and phosphorus removal filter press 5, the liquid outlet of described nickel removal filter press 3 communicates with the liquid inlet of phosphorus removal reaction precipitation tank 4; The mixed waste liquid purification device comprises a waste liquid collection tank 6, a pH adjustment tank 7, a sand filter tank 8, a nickel removal chelating resin tank 9, a phosphorus removal reaction precipitation tank 10 and a phosphorus removal sedimentation tank 11 connected in sequence, and the phosphorus removal The liquid outlet of the filter press 5...

Embodiment 2

[0075] The difference between this embodiment and embodiment 1 is:

[0076] In the step (S1), the waste chemical nickel mother liquor is electrolyzed under the action of 400A current.

Embodiment 3

[0078] The difference between this embodiment and embodiment 1 is:

[0079] In the step (S1), the waste chemical nickel mother liquor is electrolyzed under the action of 550A current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com