Preparation and application of sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler

A technology of heterotrophic denitrification and biological filler, which is applied in the field of advanced wastewater treatment and reuse, can solve the problems of difficult to further improve the treatment efficiency, uneven distribution of biofilm, long time of biofilm formation, etc., and achieve denitrification and operation effect Stabilize, enhance the population richness, and facilitate the effect of attachment growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

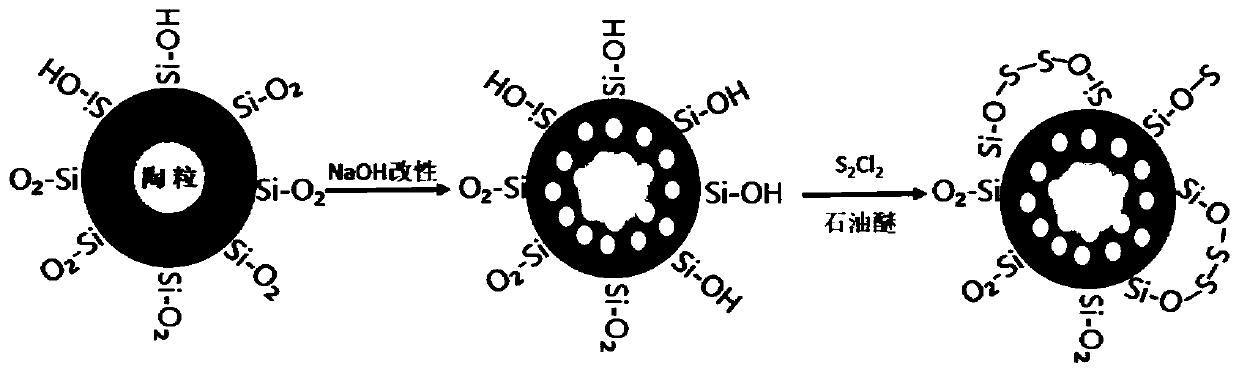

[0057] Such as figure 2 As shown, this embodiment provides a sulfur autotrophic and heterotrophic denitrification biofiller, which is a sulfur-modified ceramsite loaded with sulfur on the surface, and the sulfur combines with Si and O elements on the surface of the ceramsite to form Si -O-S, the Si-O-S are cross-linked with each other to form a grid structure. In this embodiment, the preparation method of sulfur-modified sulfur autotrophic and heterotrophic denitrification denitrification biofillers is as follows:

[0058] (1) Alkali modification:

[0059] The primary ceramsite is soaked in a potassium hydroxide solution, and washed with water after soaking to obtain the alkali-modified ceramsite;

[0060] (2) Sulfur loading:

[0061] Disperse the alkali-modified ceramsite in petroleum ether solvent, slowly add disulfur dichloride, heat and stir, and obtain sulfur-loaded sulfur-modified ceramsite after the reaction is completed, and continuously feed nitrogen during the re...

Embodiment 2

[0063] This embodiment provides a sulfur autotrophic and heterotrophic denitrification biofiller. The said biofiller is sulfur-modified ceramsite which has undergone alkali modification and sulfur loading treatment in sequence.

[0064] The preparation method of sulfur autotrophic and heterotrophic denitrification denitrification biological filler in this embodiment is as follows:

[0065] (1) Firing:

[0066] Add the binder calcium-based bentonite to the raw material dewatered sludge and clay of ceramsite to prepare raw meal powder, make the raw meal powder into raw meal balls, and roast the raw meal balls at high temperature to obtain primary ceramsite; ceramsite The mass ratio of raw material to binder is 20:1.

[0067] (2) Alkali modification:

[0068] The primary ceramsite is soaked in a potassium hydroxide solution with a mass concentration of 2%, and washed with water after soaking to obtain alkali-modified ceramsite;

[0069] (3) Sulfur loading:

[0070] Disperse t...

Embodiment 3

[0074] This embodiment provides a biological filler, which is sulfur-modified ceramsite that has undergone alkali modification and sulfur loading treatment in sequence.

[0075] The preparation method of sulfur autotrophic and heterotrophic denitrification denitrification biological filler in this embodiment is as follows:

[0076] (1) Firing:

[0077] Add the binder sodium bentonite to the ceramsite raw material fly ash and garbage residue to prepare raw meal powder, make raw meal balls from the raw meal powder, and roast the raw meal balls at high temperature to obtain primary ceramsite; ceramsite The mass ratio of raw material to binder is 25:1.

[0078] (2) Alkali modification:

[0079] The primary ceramsite is soaked in potassium hydroxide solution with a mass concentration of 3%, and washed with water after soaking to obtain alkali-modified ceramsite;

[0080] (3) Sulfur loading:

[0081] Disperse the alkali-modified ceramsite in petroleum ether solvent, slowly add d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com