Method for repairing arable soil contaminated by hexavalent chromium

A technology for arable soil and hexavalent chromium is applied in the field of remediation of hexavalent chromium-contaminated arable soil, which can solve the problems of long remediation period, easy migration, and arable soil pollution, and achieves short remediation time, strong operability and good remediation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 The effect of oxalic acid concentration on the leaching rate of hexavalent chromium in rehabilitated farmland soil and the relative root growth ratio of rice

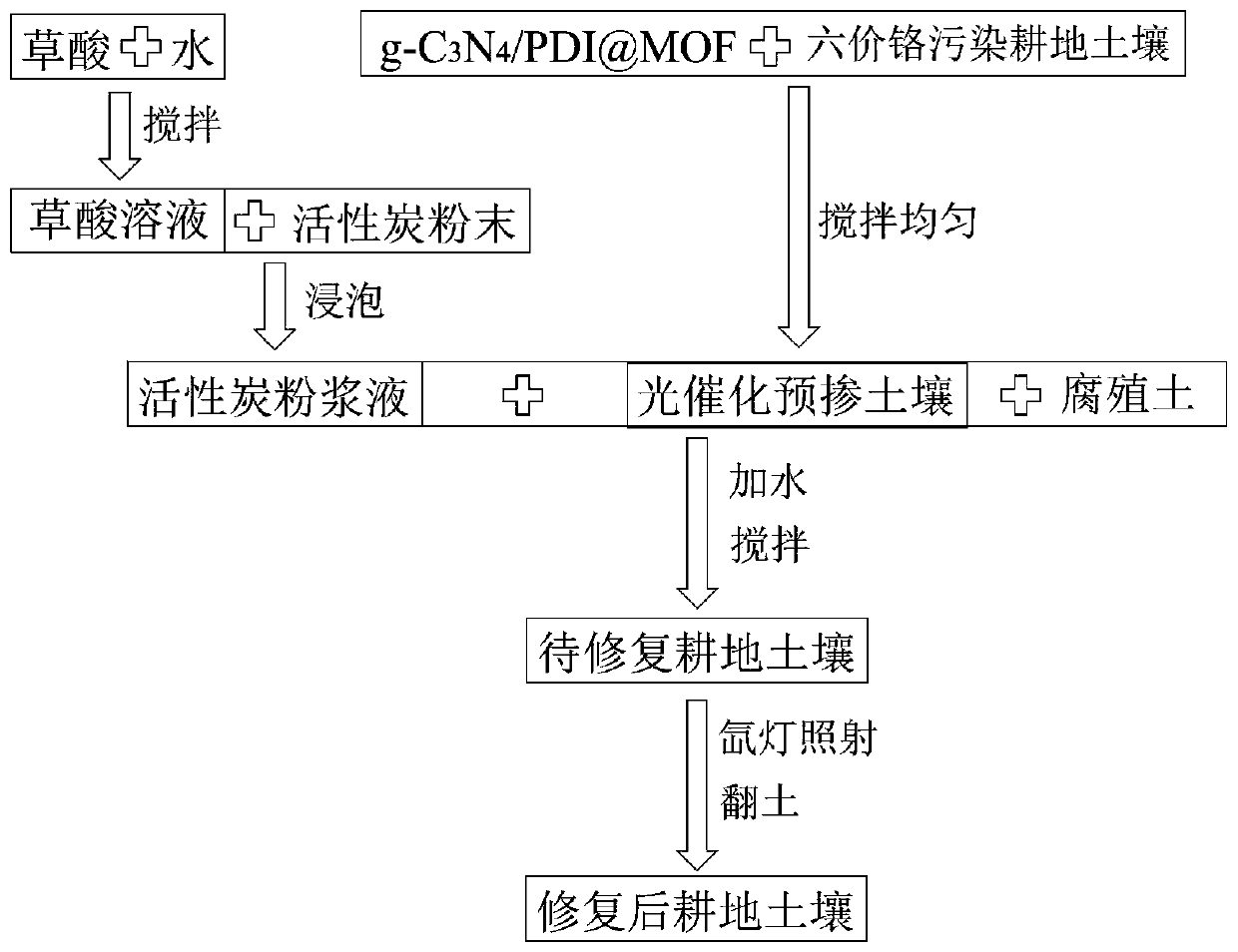

[0023] Weigh oxalic acid and dissolve it in water, stir until the oxalic acid is completely dissolved, and prepare oxalic acid solutions of different concentrations. The concentrations of the oxalic acid solutions are 0.25M, 0.35M, 0.45M, 0.5M, 1.5M, 2.5M, 2.55M, 2.65M, 2.75M. The activated carbon powder and the oxalic acid solution were weighed according to the solid-liquid ratio of 1:10 mg / mL, and the activated carbon powder was soaked in the oxalic acid solution for 2 hours to obtain an activated carbon powder slurry. Weigh g-C according to mass ratio 1:100 3 N 4 / PDI@MOF powder and hexavalent chromium pollute cultivated soil and g-C 3 N 4 / PDI@MOF powder is mixed with hexavalent chromium contaminated farmland soil and mixed evenly to obtain photocatalytic premixed soil. Weigh the photocatalytic premix...

Embodiment 2

[0033] Example 2g-C 3 N 4 / PDI@MOF powder and hexavalent chromium contaminated farmland soil quality ratio on the leaching rate of hexavalent chromium in rehabilitated farmland soil and the relative root growth ratio of rice

[0034] Weigh oxalic acid and dissolve in water, stir until the oxalic acid is completely dissolved, prepare an oxalic acid solution, the concentration of the oxalic acid solution is 2.5M. According to the solid-liquid ratio of 3:10 mg / mL, the activated carbon powder and the oxalic acid solution are weighed and the activated carbon powder is soaked in the oxalic acid solution for 3 hours to obtain the activated carbon powder slurry. Weigh g-C according to the mass ratio 0.5: 100, 0.7: 100, 0.9: 100, 1: 100, 3: 100, 5: 100, 5.1: 100, 5.3: 100, 5.5: 100 3 N 4 / PDI@MOF powder and hexavalent chromium pollute cultivated soil and g-C 3 N 4 The / PDI@MOF powder is mixed with the corresponding hexavalent chromium contaminated farmland soil and stirred evenly to obtain...

Embodiment 3

[0044] Example 3 Effect of humus soil content on the leaching rate of hexavalent chromium in the rehabilitated farmland soil and the relative root growth ratio of rice

[0045] Weigh oxalic acid and dissolve in water, stir until the oxalic acid is completely dissolved, prepare an oxalic acid solution, the concentration of the oxalic acid solution is 2.5M. Weigh the activated carbon powder and the oxalic acid solution according to the solid-liquid ratio of 3:10 mg / mL, and soak the activated carbon powder in the oxalic acid solution for 3 hours to obtain an activated carbon powder slurry. Weigh g-C according to the mass ratio of 5:100 3 N 4 / PDI@MOF powder and hexavalent chromium pollute cultivated soil and g-C 3 N 4 The / PDI@MOF powder is mixed with the corresponding hexavalent chromium contaminated farmland soil and stirred evenly to obtain the photocatalytic premixed soil. According to the mass ratio 100: 2.5: 10, 100: 3.5: 10, 100: 4.5: 10, 100: 5: 10, 100: 10: 10, 100: 15: 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com