Hydraulic brake clamp for straddle type monorail vehicle

A hydraulic braking and common braking technology, applied in the direction of brake type, brake actuator, axial brake, etc., can solve the problem of troublesome replacement of brake pads, and achieve fast gap between discs, compact structure, easy installation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

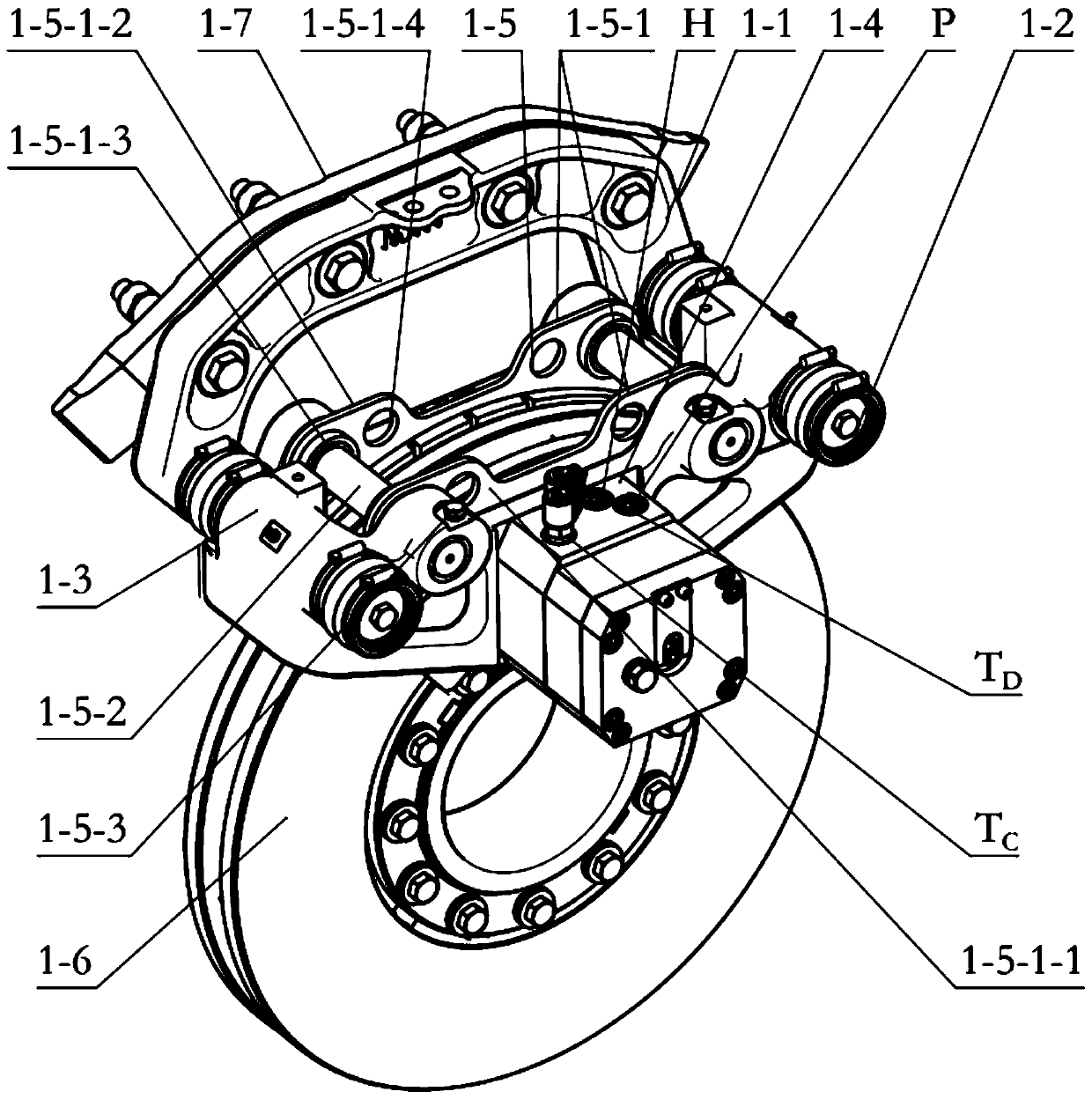

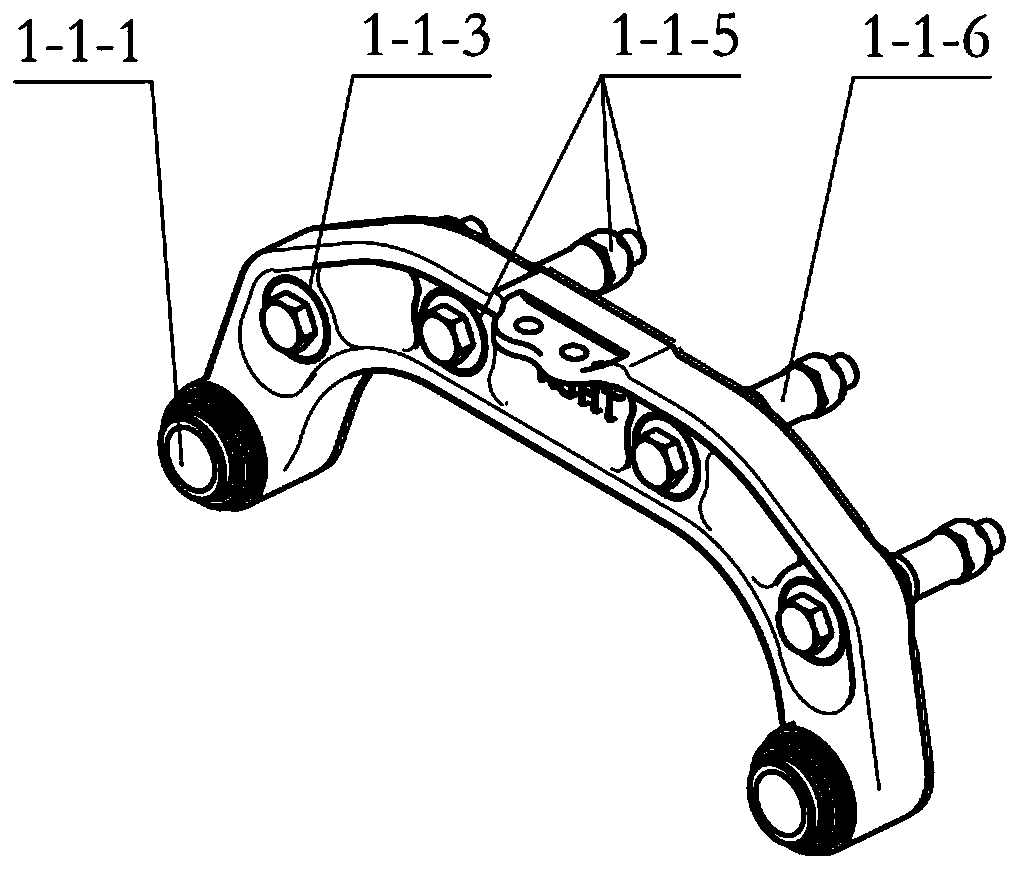

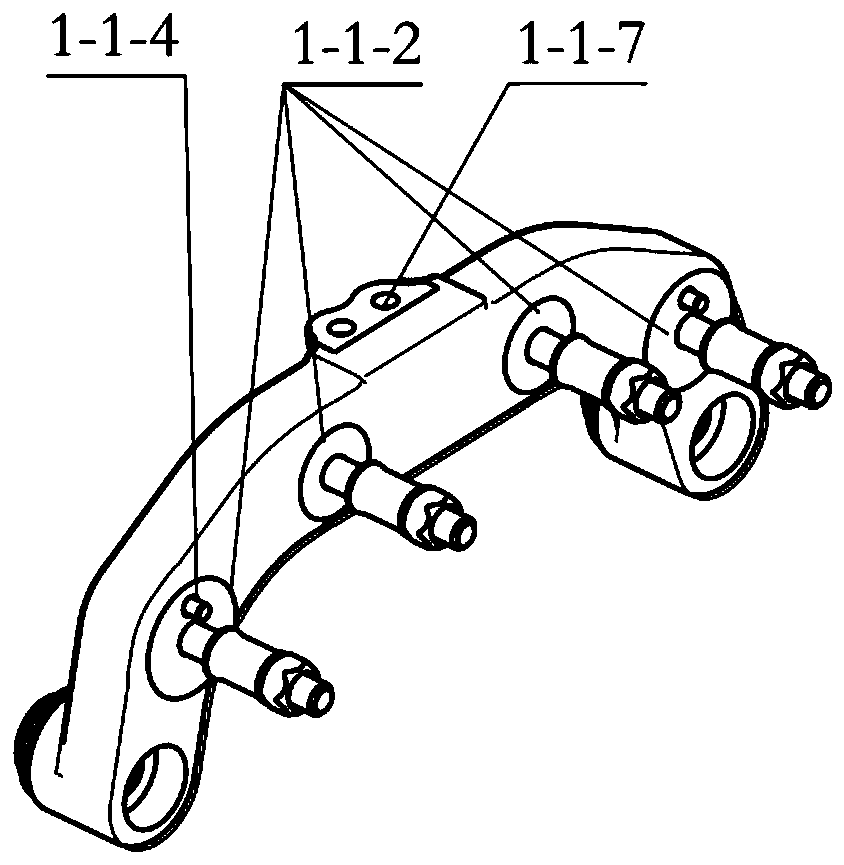

[0031] Such as figure 1 As shown, the hydraulic brake caliper of this embodiment includes a mounting base assembly 1-1, which is connected to the sliding pin shaft 1-2 of the mounting base assembly 1-1 through bolts, and is connected to the mounting base assembly 1-1 through a sliding pin shaft. The caliper body 1-3, the brake cylinder 1-4 fixed on the caliper body 1-3, the brake pad assembly 1-5 arranged on both sides of the caliper body 1-3, the front end of the brake cylinder is suitable for the brake pad assembly Press towards the direction of the brake disc, the two ends of the caliper body are connected to the mounting base assembly 1-1 through sliding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com