Roller ring axial aligning positioning adjusting mechanism of double-roller crusher

A double-roller crusher and axial alignment technology, which is applied in grain processing and other directions, can solve problems such as rework, waste of manpower and time, and incorrect axial position of the roll ring, etc., to achieve easy machining, ensure dimensional accuracy, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

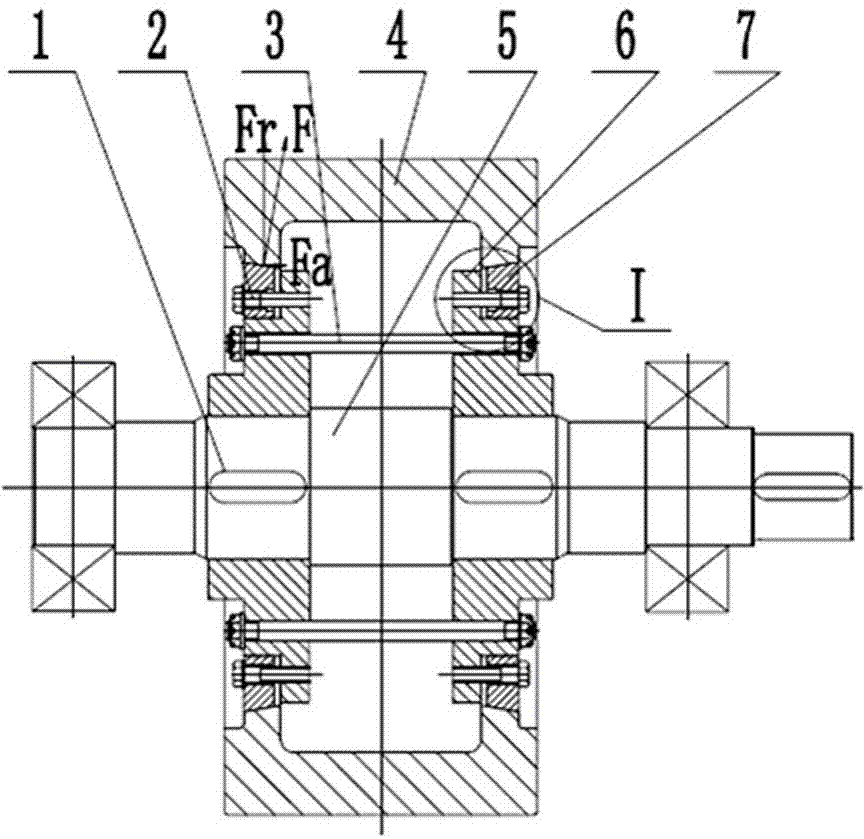

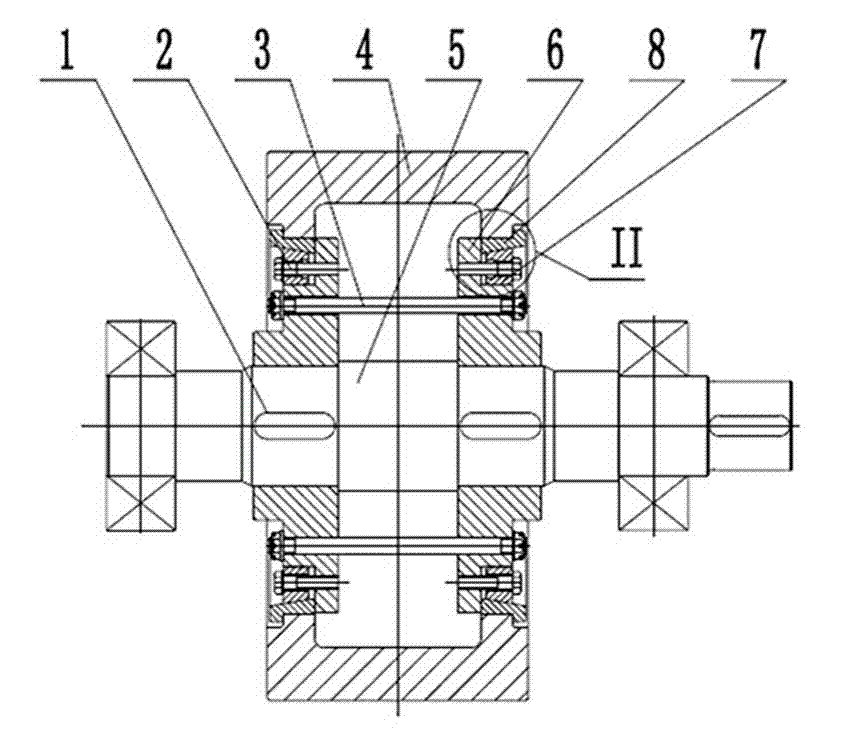

[0031] Example: such as image 3 with Figure 4 As shown, a roll ring axial alignment and positioning adjustment mechanism of a double roll crusher includes a roll ring 4, two hubs 6, two tension rings 8, two tension rings 7, and a roller shaft 5. Two sets of tightening screws 2, one set of tie rod bolts 3, and two keys 1. The hub 6 is connected with the roller shaft 5 by the key 1, and is axially positioned on the shaft by the shaft shoulder. The left and right hubs 6 are tightened and fixed by the tie rod bolts 3. On the hub 6, the radial and axial positioning of the roll ring 4 on the roll shaft 5 is realized.

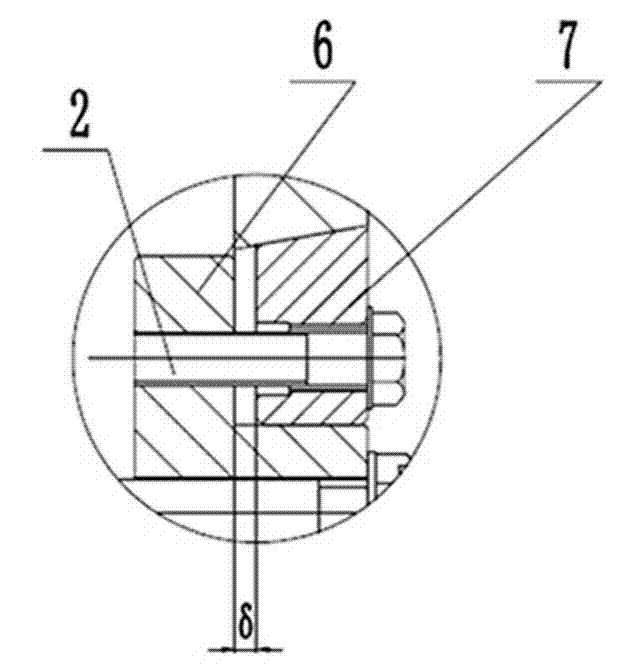

[0032] The tensioning and positioning ring 8 is designed with a positioning plane A and a positioning plane B. The distance between the two planes is L. The axial mating surface of the roller ring 4 and the tensioning and positioning ring 8 is a cylindrical surface. The axial length of the two mating surfaces is The same, both are L; the tensioning positioning ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com