Conductive nozzle for gas shielded welding

A technology of gas shielded welding and conductive nozzles, which is applied in the direction of electrode accessories and electrode characteristics, can solve the problems of affecting work progress, increasing production costs, and not replacing parts, so as to save processing costs, improve efficiency, and facilitate machining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

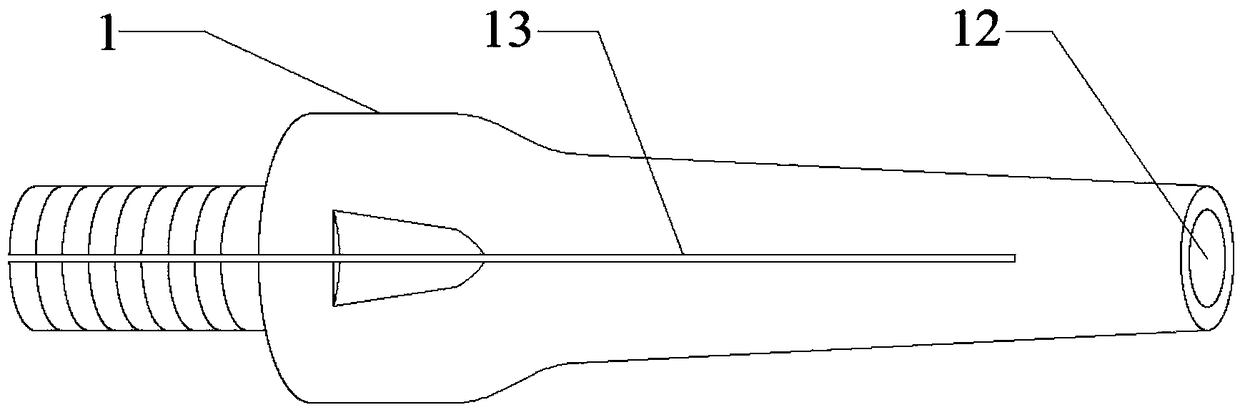

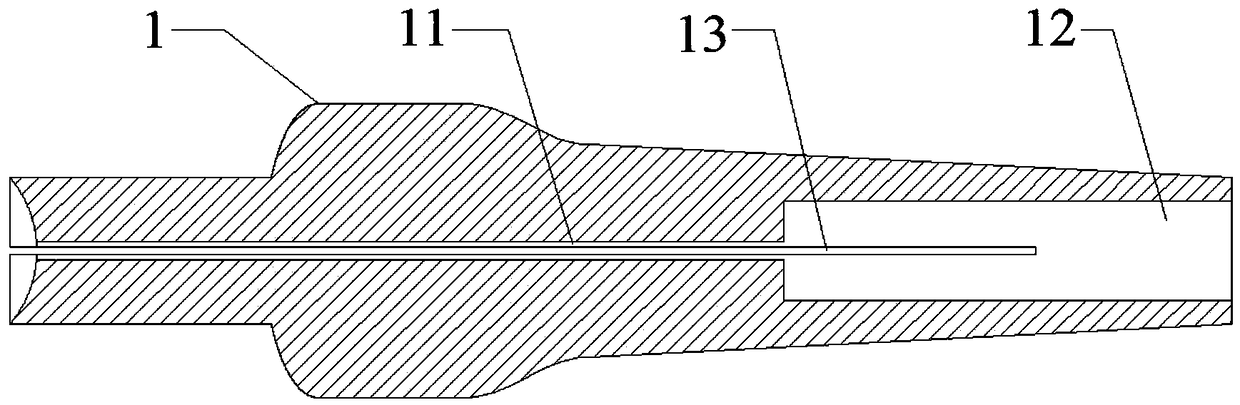

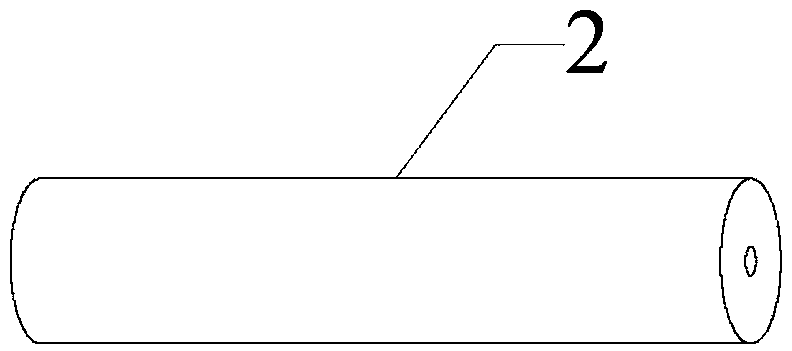

[0014] A conductive tip for gas shielded welding, comprising a conductive tip body 1, a through hole 11 is provided in the middle of the conductive tip body 1, and a cylindrical conductor 2 with a through hole in the axial direction, and a blind hole is provided at one end of the conductive tip body 1 12. The diameter of the blind hole 12 is larger than the diameter of the through hole 11, the blind hole 12 is coaxial with the through hole 11, the blind hole 12 and the through hole 11 form a stepped hole, and the cylindrical conductor 2 is mounted on In the blind hole 12, it matches with the blind hole 12 and is detachable.

[0015] The diameter of the through hole on the cylindrical conductor 2 is 4mm, and the axis direction of the conductive tip body 1 is provided with a dividing groove 13, and the length of the dividing groove 13 accounts for 8 / 9 of the total length of the conductive tip body 1, and the conductive tip body 1 The total length is 45 mm, and the length of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com