Movement transmission device, in particular for a robot arm

A transmission and motion technology, applied in transmissions, friction transmissions, manipulators, etc., can solve complex, difficult, expensive and other problems, and achieve the effect of simplified shape, good precision, and simplified machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

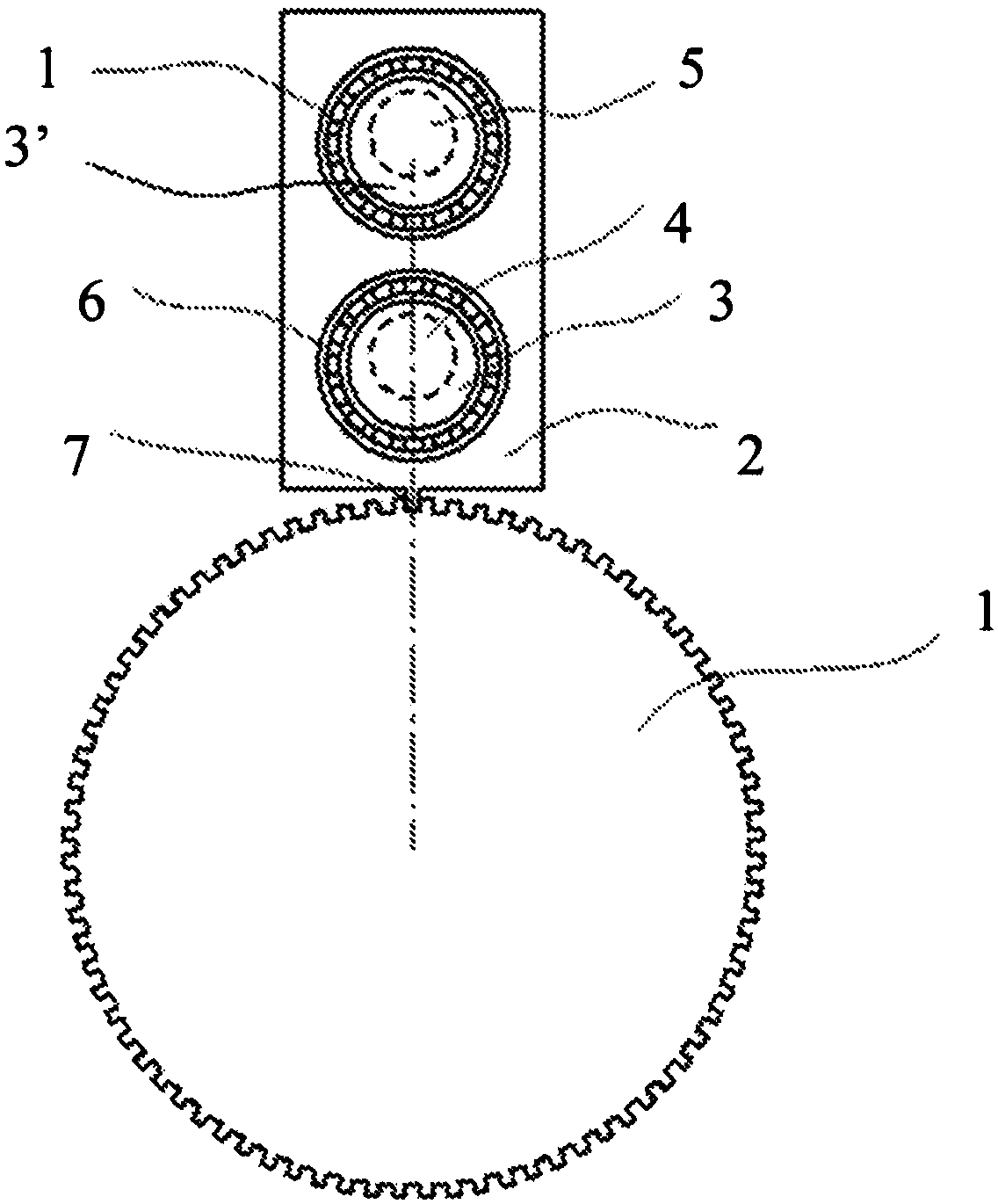

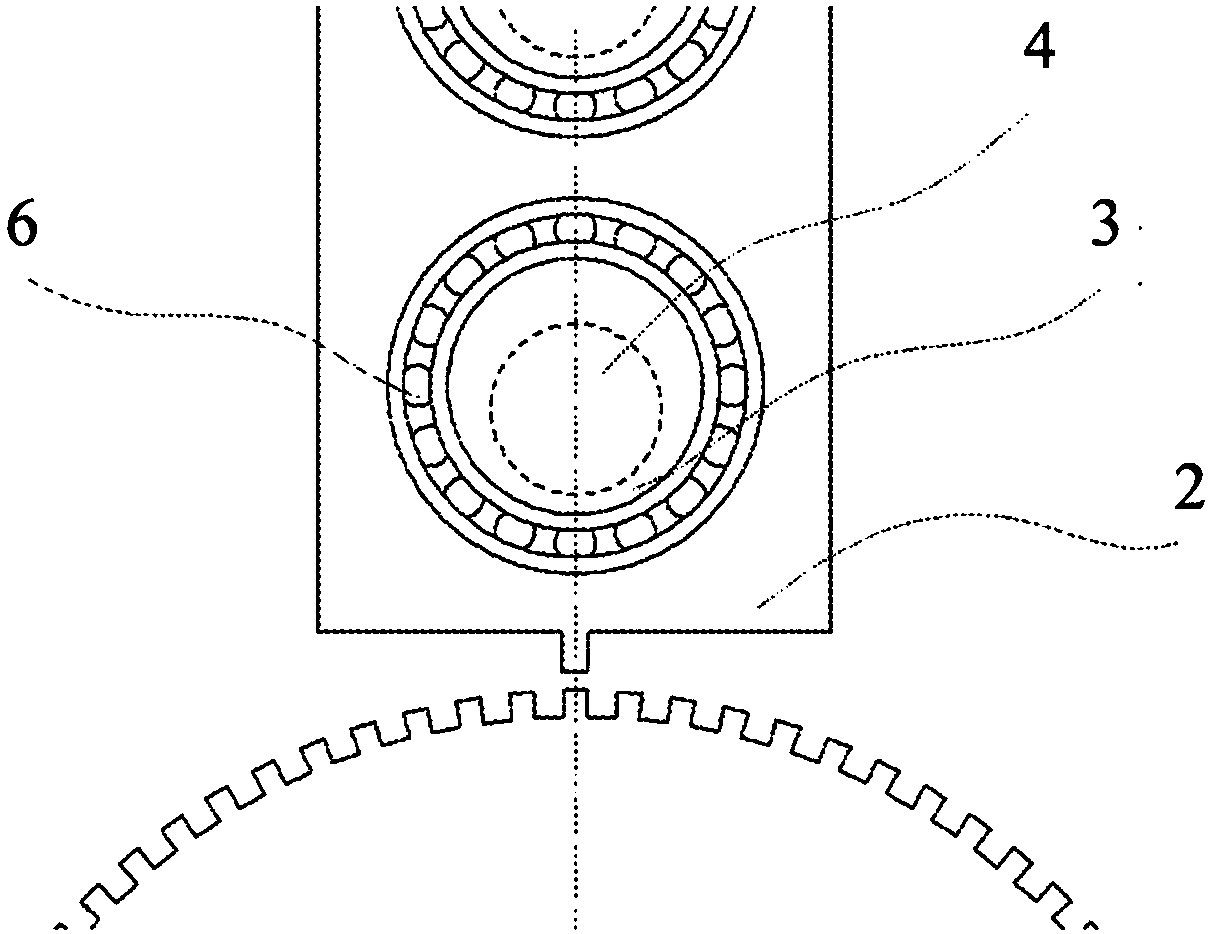

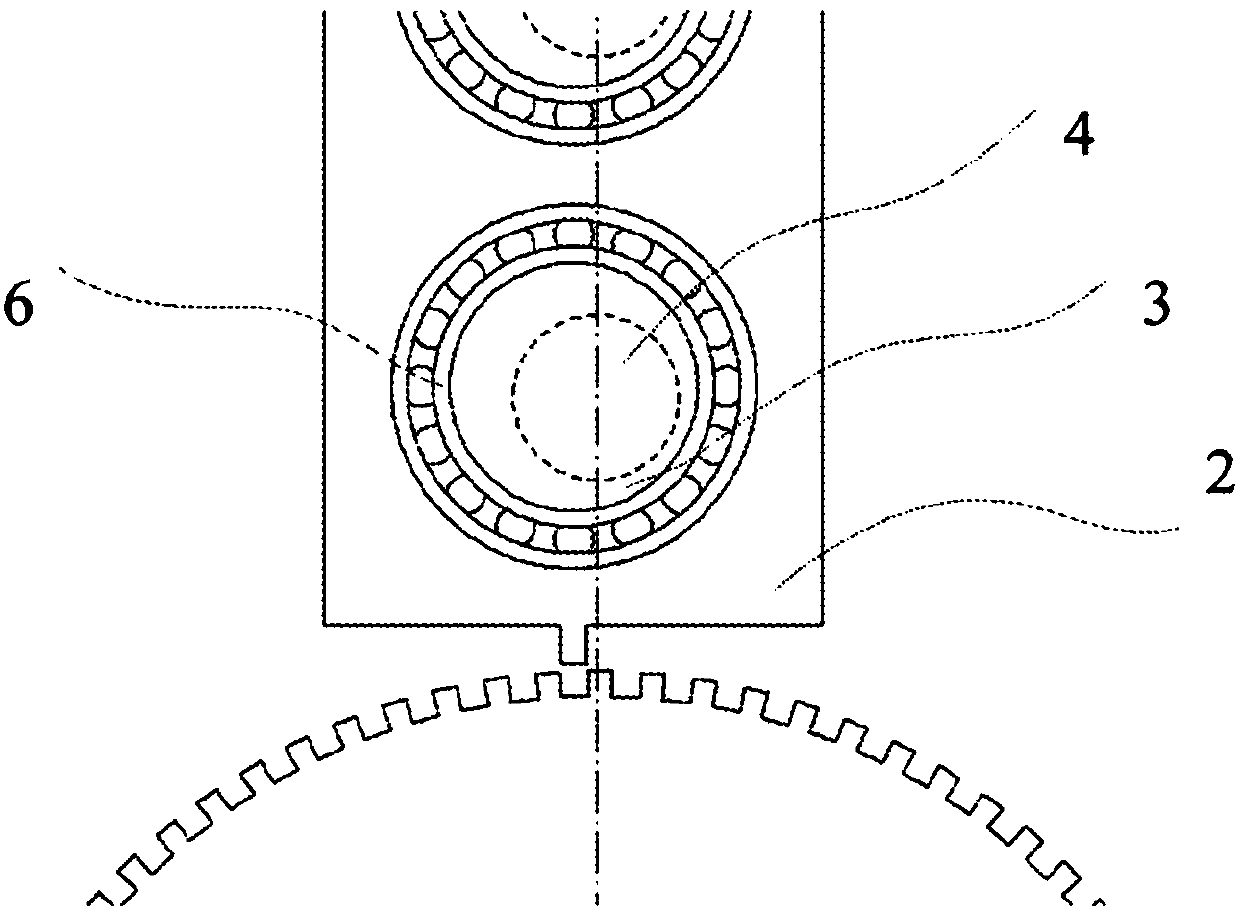

[0037] refer to Figures 1 to 7, the basic principle of the invention will be explained in the case of the wheel having a notch made on its outer periphery, but it also applies to the case where the crown has a notch made on its inner peripheral surface or even Applies to the rack case. Such as figure 1 As shown, the reducer includes an output shaft ( Figures 1 to 7 not shown), the shaft 4 and the arm 2 for motion transmission between the shaft 4 and the wheel 1 . The wheel 1 comprises a series of notches on its outer surface. The number of notches is a function of the desired reduction ratio, eg for a reduction ratio of 1 / 80 there are 80 notches. The arm 2 is preferably mounted on a cylindrical bearing 3 of the shaft 4 by means of a ball bearing 6 or a flat washer. The cylindrical bearing 3 has a slight eccentricity with respect to the axis of rotation of the shaft 4 . Part 2 , comprising teeth 7 incorporated in recesses of wheel 1 , is preferably mounted on cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com