Process board clamping cart for multi-directional adjustable vehicle workpieces

A process board and adjustable technology, which is applied in the field of fixture installation and positioning device, fixture fixture installation and positioning device for lamp parts processing, can solve problems such as potential safety hazards, and achieve easy machining and stable work center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

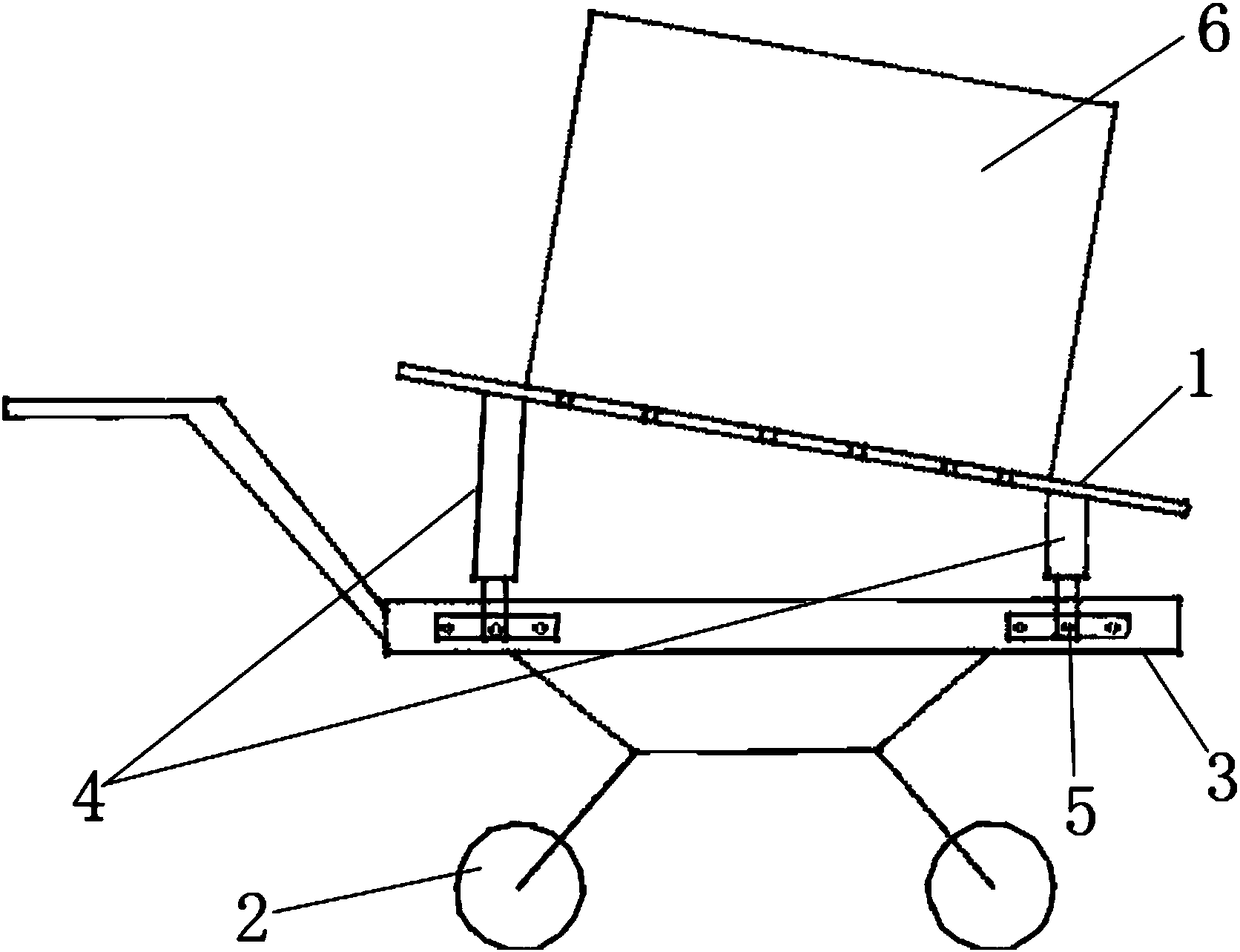

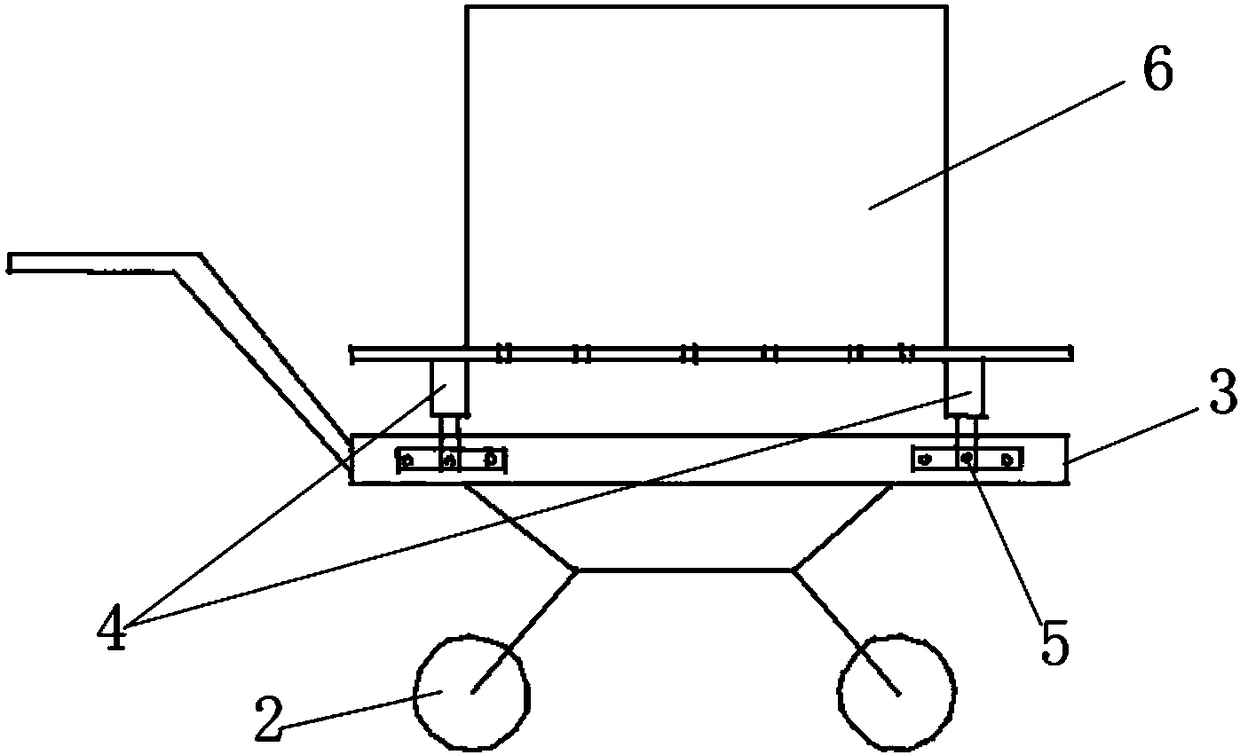

[0029] A multi-directional adjustable vehicle workpiece process plate clamping vehicle, including a process plate for installing vehicle workpieces,

[0030] Place the process board on the trolley floor of the clamping car with rollers at the bottom to move the process board quickly and conveniently. A hydraulic rod is installed between the process board and the four ends of the cart bottom of the clamping car. The height of the hydraulic rod is It can be adjusted, and through the adjustment of the height of each hydraulic rod, the rise and fall of each end of the process plate can be realized.

[0031] By adjusting the height of each hydraulic rod, the relative drop at each end of the process plate is realized, thereby realizing the adjustment of the rotation angle of the process plate.

[0032] The process board is provided with a rectangular array of screw holes for fixing workpieces.

[0033] The bottom of the process board is provided with a hole fixed to the hydraulic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com