Production process of tobacco tipping paper

A technology for cigarette tipping paper and production process, applied in the field of tobacco paper, can solve the problems affecting the quality of cigarette tipping paper products, paper wrinkling or deformation, etc. The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

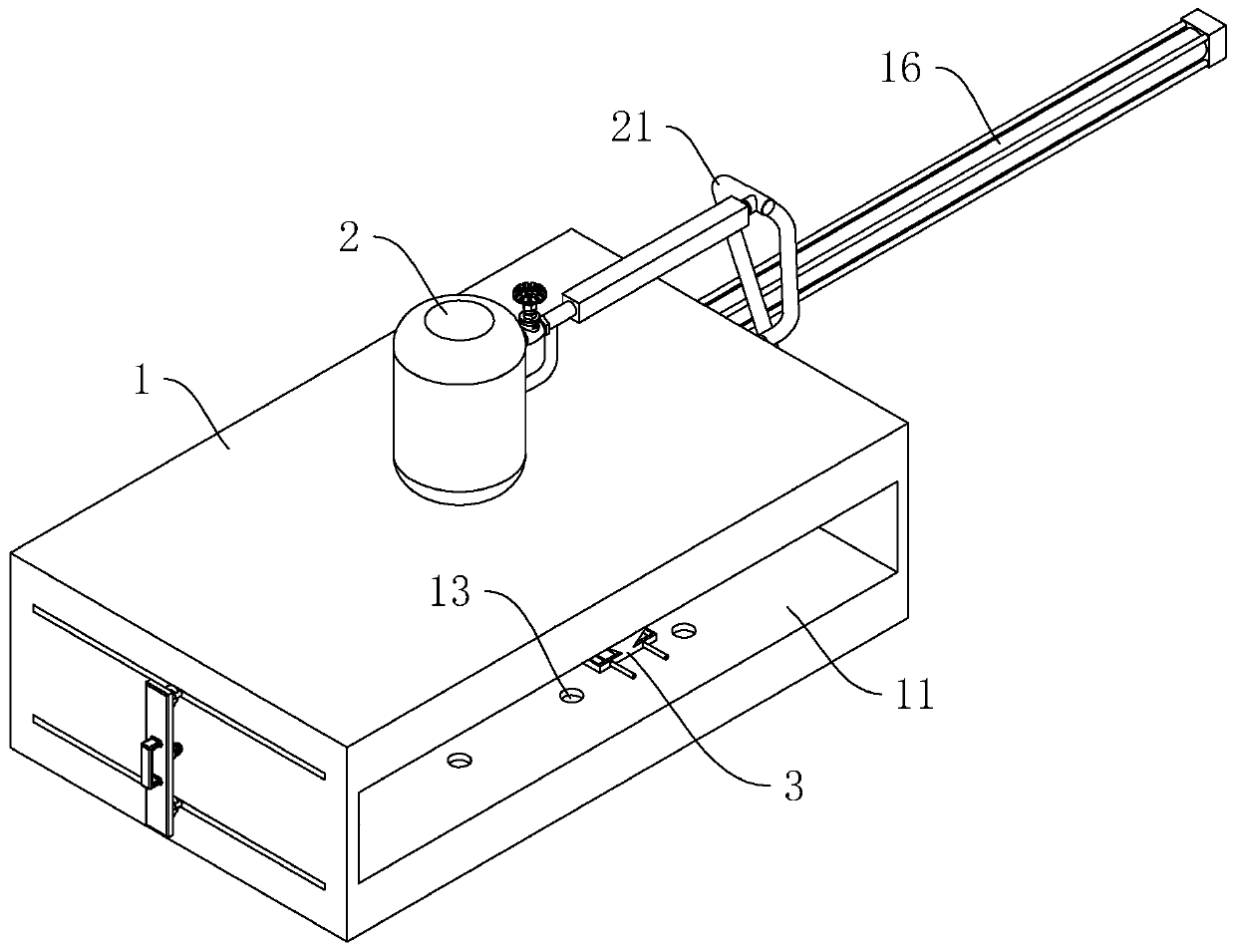

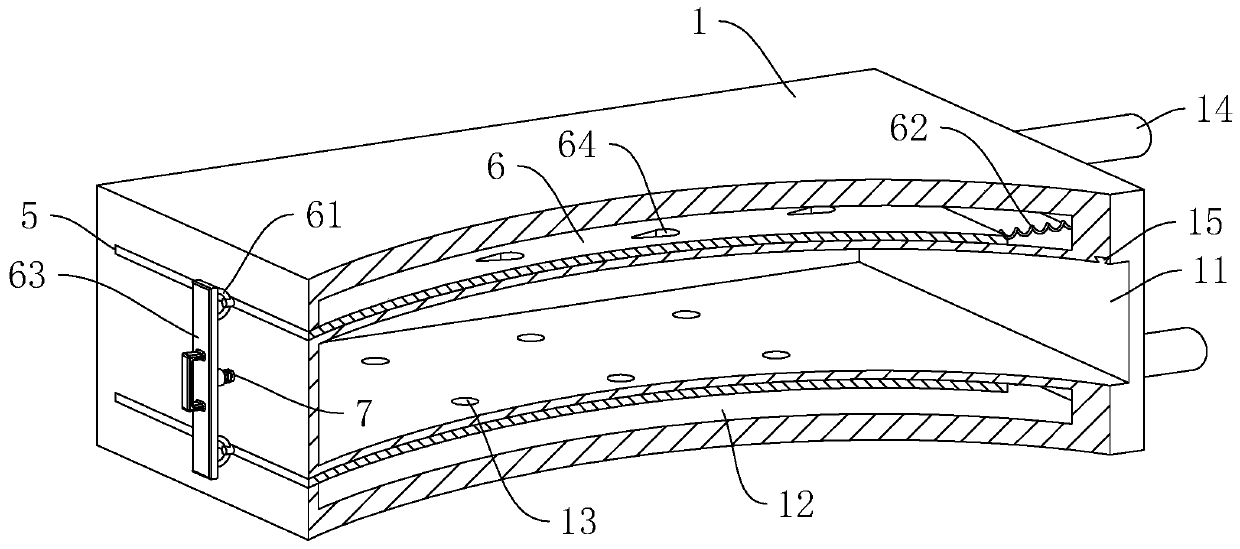

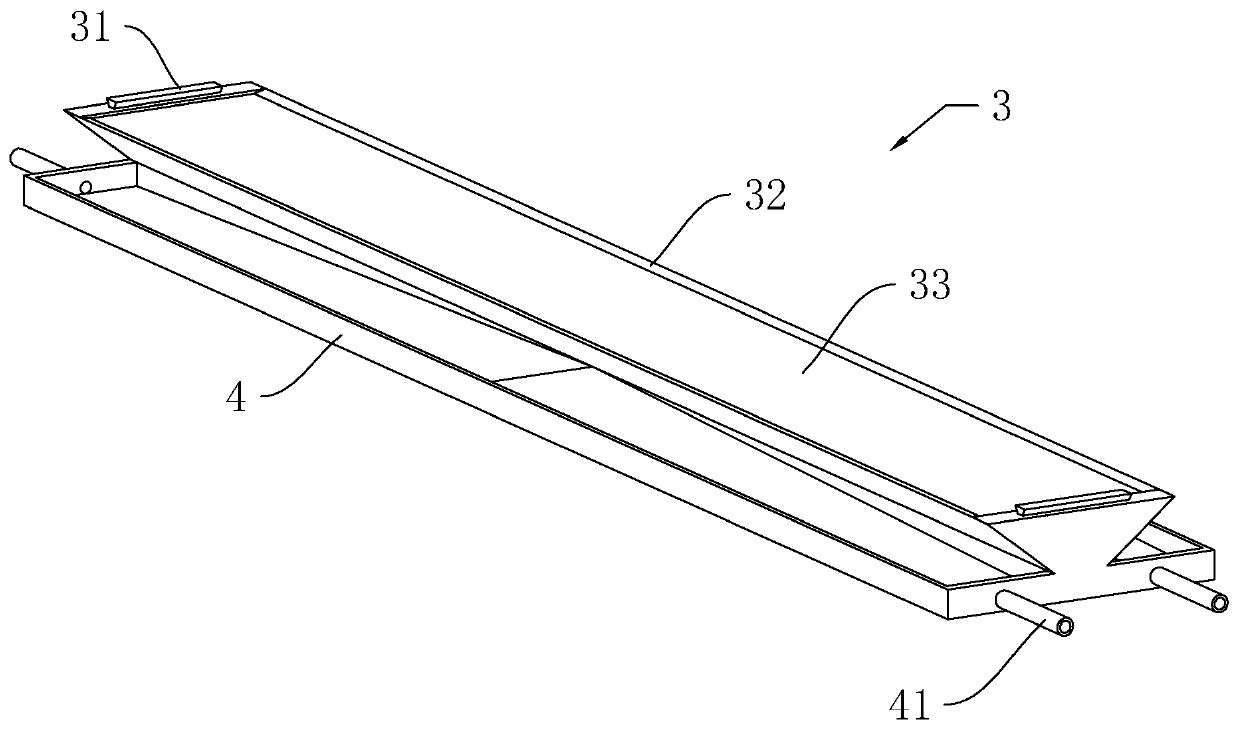

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] A production process for cigarette tipping paper, comprising the steps of:

[0053] S1, humidification treatment, using a humidifying device to humidify the paper.

[0054] S2, printing, using a printing machine to print paper.

[0055] S21, quality inspection, testing the printed paper to ensure that the color of the ink meets the requirements, and uniformly collect unqualified products.

[0056] S3, humidifying treatment, using a humidifying device to humidify the paper.

[0057] S4, hot stamping, using a hot stamping machine to hot stamp the surface of the printed paper.

[0058] S41, quality inspection, testing the hot stamped paper to ensure that the hot stamping coating on the surface of the paper is complete and smooth, and at the same time uniformly collect unqualified products.

[0059] S5, humidifying treatment, using a humidifying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com