A kind of thermoplastic cable insulating material and preparation method thereof

A cable insulation and preparation process technology, applied in plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems affecting cable transportation, installation and use, large cable bending radius, and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the thermoplastic cable insulating material described in the above technical solution, comprising: mixing and banburying polypropylene resin, hydrogenated styrene-butadiene-styrene block copolymer and antioxidant, Get cable insulation.

[0036] Wherein, the characteristics of the polypropylene resin, hydrogenated styrene-butadiene-styrene block copolymer and antioxidant are the same as those described in the above technical scheme, and the characteristics of the type, amount and source of antioxidant Repeat.

[0037] In the present invention, the banburying can be carried out by means of an internal mixer, and the banburying is mixed in a mixer of a torque rheometer. The temperature of the banburying is preferably 200 to 250°C, and more preferably 210 to 230°C. The time of the banburying is preferably 10-15 min. In the present invention, the rotational speed of the banburying is preferably 40 to 70 r / min, mor...

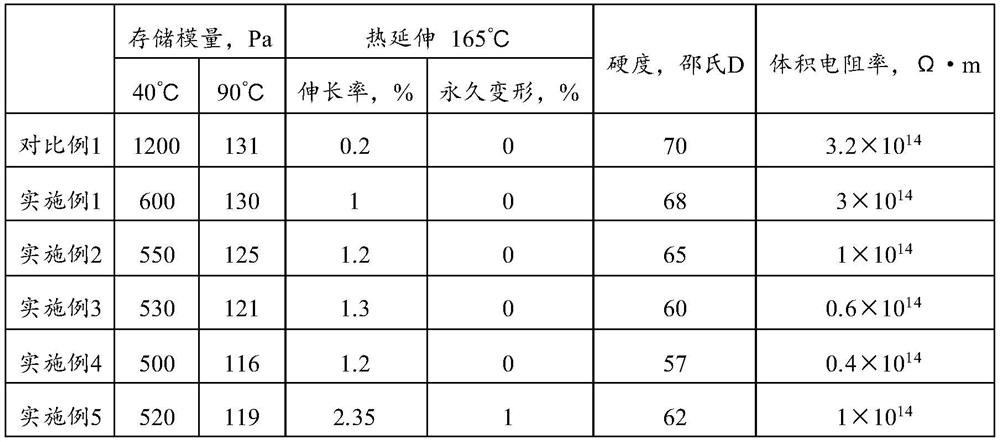

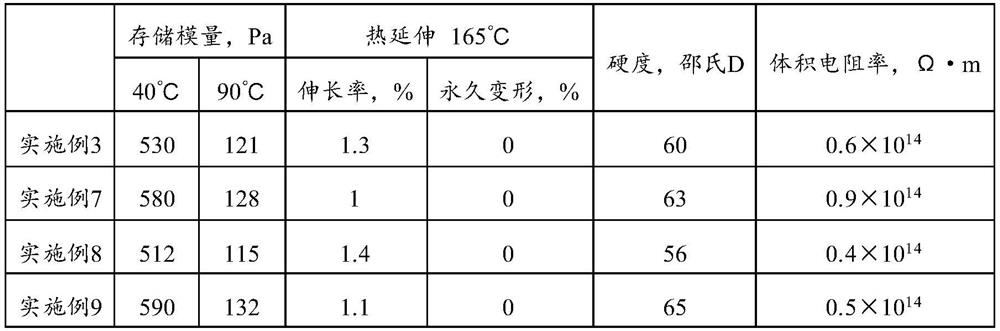

Embodiment 1

[0040] Raw materials: 100 parts of copolymerized PP, melt index is 2.2g / 10min, ethylene content is 4%; 10 parts SEBS, molecular weight is 250,000, styrene content is 30%; 0.5 part of antioxidant 1010;

[0041] The above-mentioned raw materials were put into an internal mixer, and were mixed at 210° C. and a rotating speed of 60 rpm for 12 minutes, and the cable insulating material was obtained by melt blending.

Embodiment 2

[0043] Raw materials: 100 parts of copolymerized PP, melt index is 2.2g / 10min, ethylene content is 4%; 15 parts SEBS, molecular weight is 250,000, styrene content is 30%; 0.5 part of antioxidant 1010;

[0044] The above-mentioned raw materials were put into an internal mixer, and were mixed at 210° C. and a rotating speed of 60 rpm for 12 minutes, and the cable insulating material was obtained by melt blending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com