Method for preparing taurine

A technology of taurine and taurine, which is applied in the preparation of sulfonic acid, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of increasing environmental protection risks, the limitation of utilization rate of taurine mother liquor, etc., and achieves reduction of production energy consumption. , The effect of improving product yield and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

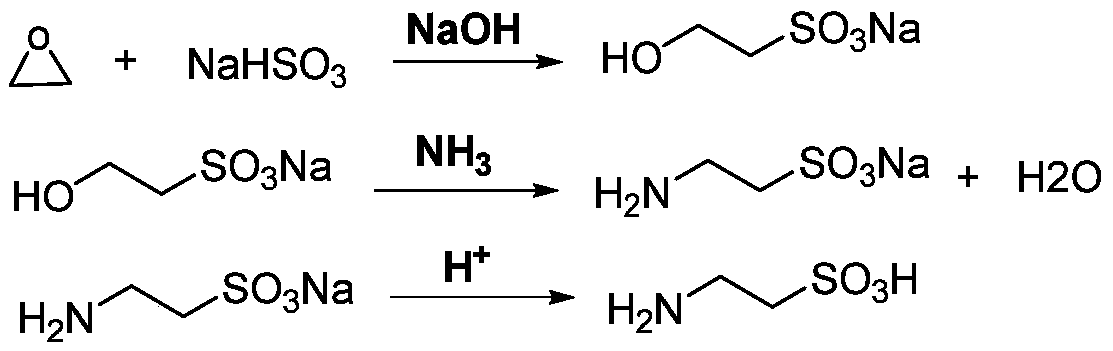

Method used

Image

Examples

Embodiment 1

[0048] This embodiment mainly introduces the process of performing various treatments on the acidic cationic resin column used in the present invention.

[0049] Pretreatment: Wetly load Amberlyst 15 type acidic cation exchange resin into the exchange column, retain the water layer about one-fifth of the column height in the upper layer of the resin, and vibrate the ion exchange column in a small range to make the resin dense. Under the protection of nitrogen, use 2BV, 0.1mol / L sulfurous acid to pass through the resin in the ion exchange column at a flow rate of 2.0BV / h, then wash the residual sulfurous acid not absorbed by the resin with deionized water, and monitor the effluent liquid online When the pH value of the effluent is about 6.5±0.5, stop washing.

[0050] Regeneration treatment: first wash the acidic cation exchange column with deionized water, when the pH value is about 7, the material is cleaned, and then use 2BV, 0.1mol / L sulfurous acid solution to pass through ...

Embodiment 2

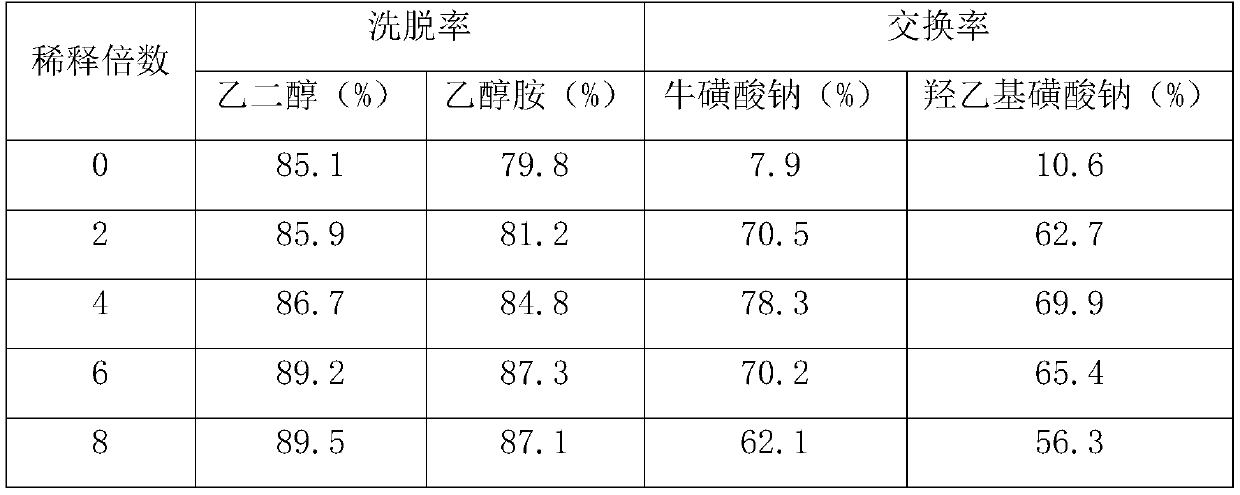

[0054] The purpose of this example is to verify the acidifying effect of acidic cation exchange resin on sodium taurate and the mixture of sodium taurate and sodium isethionate under laboratory conditions. Get the sodium taurate solution of 0.5mol / L respectively, and the sodium taurate (i.e. taurine alkali metal salt) of 0.5mol / L and the sodium isethionate (i.e. isethionate) of 0.5mol / L Acid and alkali metal salts) mixed solution at normal temperature, with the speed of 1.0BV / h, pass through different types of acidic cationic resins (Amberlyst 15 type, 732 type) respectively, detect resin to pure sodium taurate and sodium taurate and sodium isethionate mixtures, we have found that these resins have acidifying capabilities both for sodium taurate and for mixtures of sodium taurate and sodium isethionate, especially type 732 resin and Amberlyst 15 Type resin has a good acidification effect, and the one-time acidification rate can reach more than 85%.

[0055] The taurine alkali...

Embodiment 3

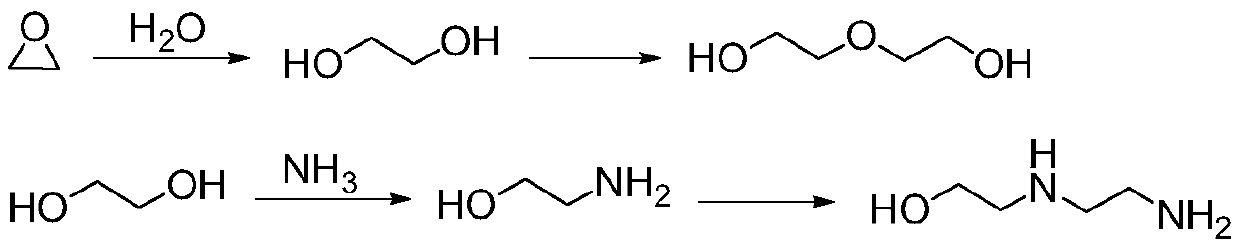

[0057] This example simulates the industrial method for preparing taurine by the ethylene oxide method to obtain a solution similar to the mother liquor composition after taurine is extracted, that is, containing about 14% of sodium taurine and about 14% of sodium isethionate. A mixed solution of about 10%, ethanolamine content of about 5.5%, and ethylene glycol content of about 4.5%.

[0058] Concrete method is: in the beaker of 10 liters, put into the ethylene glycol of 270g, the ethanolamine of 330g, the sodium taurate of 840g, the sodium isethionate of 600g, add pure water, to the scale of 5 liters, It is configured into a solution with 4.5% ethylene glycol content, 5.5% ethanolamine content, 14% sodium taurate content and 10% sodium isethionate content.

[0059] In other similar occasions, different proportions of the above-mentioned solutions can be prepared according to actual needs, all of which can produce the required technical effects of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com