Double component filaments, nonwoven net containing them and forming method thereof

A two-component, woven fiber web technology, applied in the direction of nonwovens, rayon manufacturing, textiles and paper, can solve the problem of increasing energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

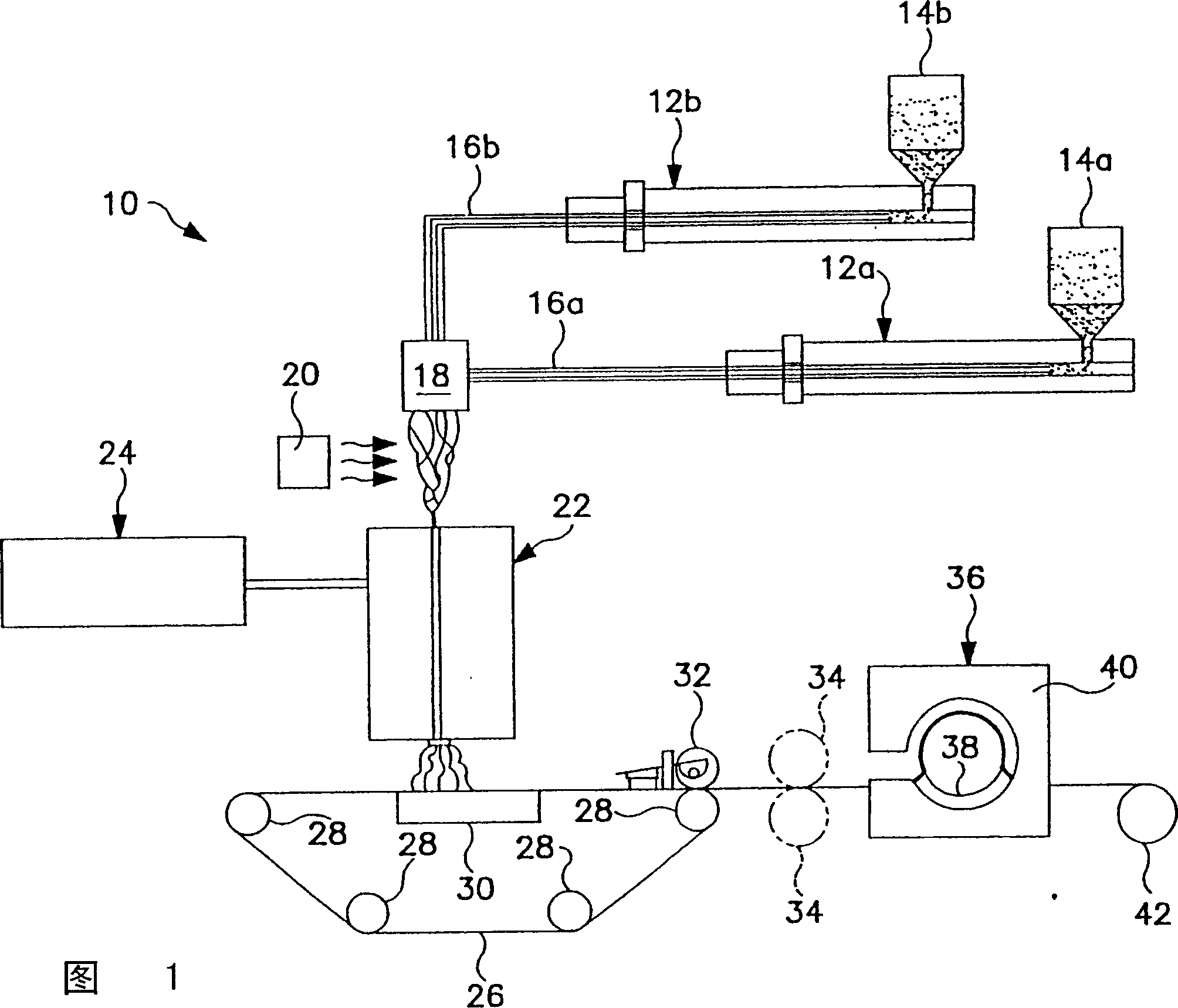

Method used

Image

Examples

example 1

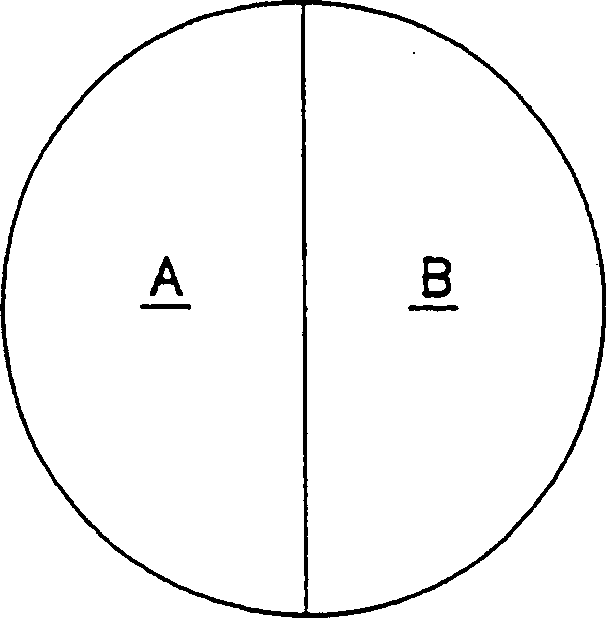

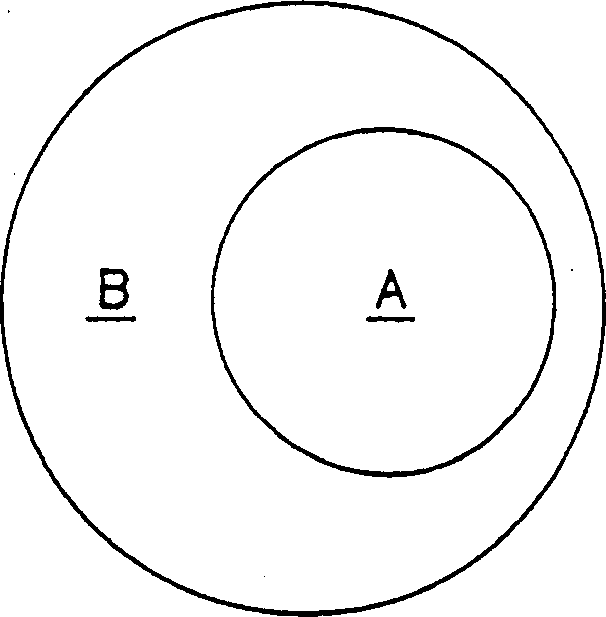

[0087] A spunbond bicomponent filament web having a basis weight of 2.6 ounces per square yard was produced by the method described in US Patent 5,382,400 to Pike et al. The bicomponent filaments used to make the web comprise a polyethylene component and a polypropylene component, arranged in a side-by-side configuration. The polyethylene used to make the filaments was ASPUN XU61800, supplied by Dow Chemical Company.

[0088] On the other hand, the polypropylene used to make the filaments was ESCORENE 3445, supplied by Exxon Corporation, which also contained 2 wt% titanium dioxide. According to the present invention, the polypropylene also contains 2.5% by weight of MASIL SF-19 nonionic ethoxylated silicone surfactant, supplied by PPG Industries. The nonionic surfactant added to the polypropylene according to the invention acts as a curl enhancing additive.

[0089] The polypropylene and polyethylene components were fed separately into the respective extruders. The extruded...

example 2

[0094] The process described in Example 1 for making bicomponent filaments and making nonwoven webs from the filaments was repeated. However, in this example, instead of MASIL SF-19 nonionic surfactant, ANTAROX BL-214 supplied by Rhone Planck was used. ANTAROX BL-214, an ethoxylated alkyl ether, was added to the polypropylene component in an amount of 3 wt%.

[0095] During production, the fiber draw (suck) pressure was 3 psi, the polymer throughput was 0.5 ghm, and the through-air bonder temperature was 250°F. During drawing, the tow is exposed to air at a temperature of only about 54°F to crimp the tow. The tow was drawn to a thickness of about 2.2 denier.

[0096] The resulting fabric has a basis weight of 3.5 ounces per square yard and a density of 0.020.g / cm 3 .

[0097] Similar to the fabric prepared in Example 1, the nonwoven web prepared with ANTAROX BL-214 was found to have high loft and was instantly wettable with water. It was also observed that the bicomponent...

example 3

[0099] The procedure described in Example 2 was repeated. Specifically, the polypropylene component still contained 3 wt% ANTAROX BL-214 nonionic surfactant. Unlike Example 2, however, the polymer throughput through the spin pack was 0.4 ghm.

[0100] In this example, the filament has a denier per filament of 1.7 and the resulting fabric has a basis weight of 3.1 ounces per square yard and a density of 0.021 g / cm 3 . Again, a nonwoven web with considerable loft was produced and it was instantly wettable with water. It was also found in this example that low denier filaments can be produced in accordance with the present invention which can still be highly crimped simply by exposing the filaments to air near room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com