Method for manufacturing flat panel display equipment

A technology for equipment manufacturing and flat-panel display, which is applied in identification devices, instruments, nonlinear optics, etc., to solve the problems of inability to bend, inability to achieve bending and curling, poor characteristics, etc., and achieve the effect of continuous bending and folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment provides a structure of a bendable flat panel display device and a manufacturing method thereof. Since there are many types of flat-panel display devices, the structure of the flat-panel display device and its manufacturing method of the present invention will be described in detail below by taking the LCD panel as an example and referring to the accompanying drawings.

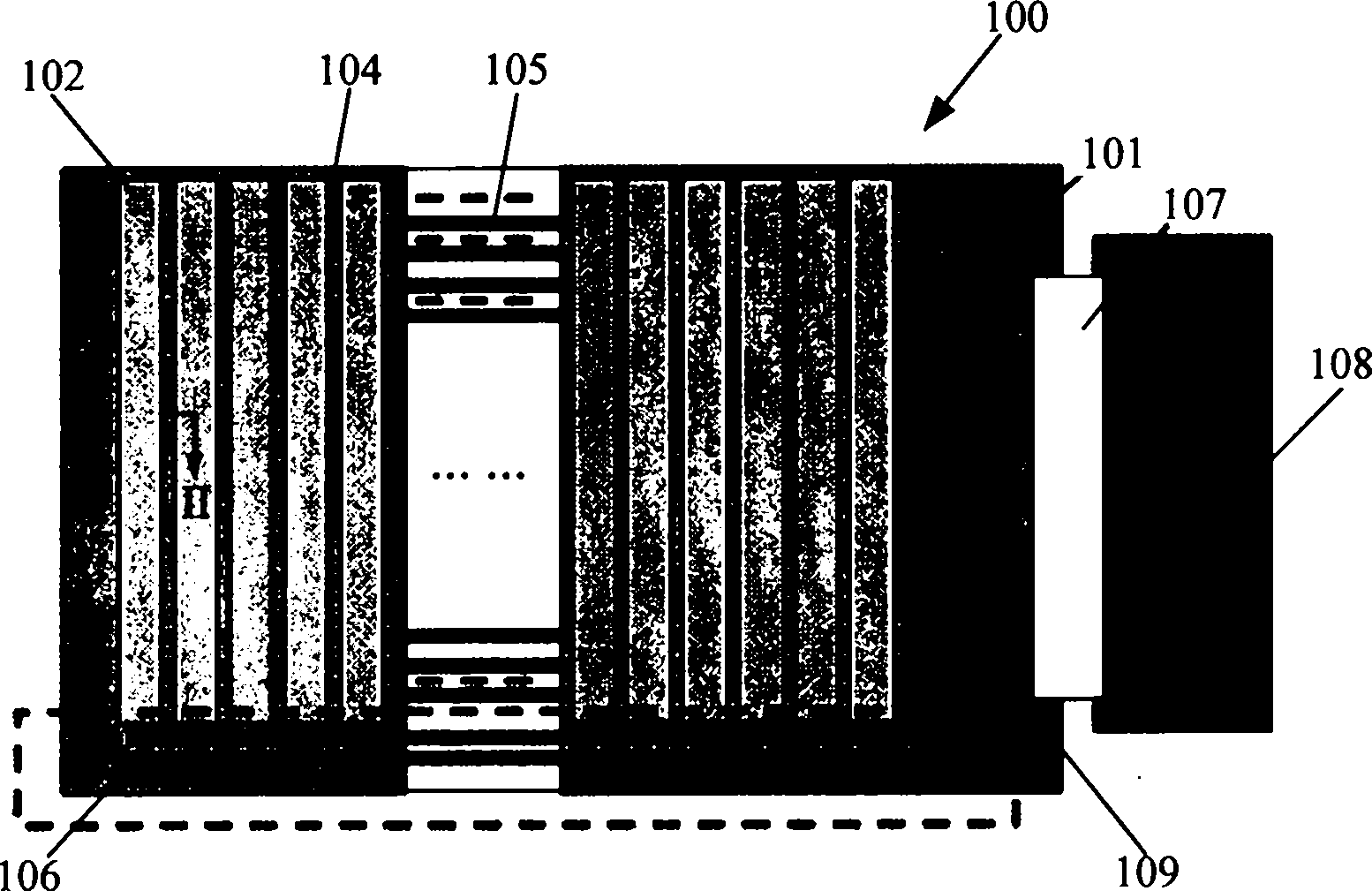

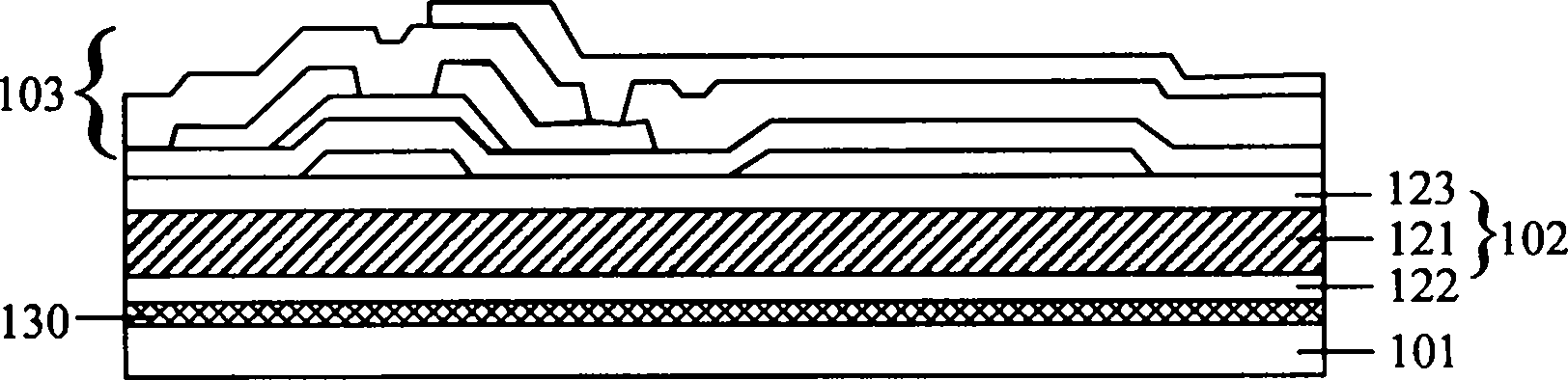

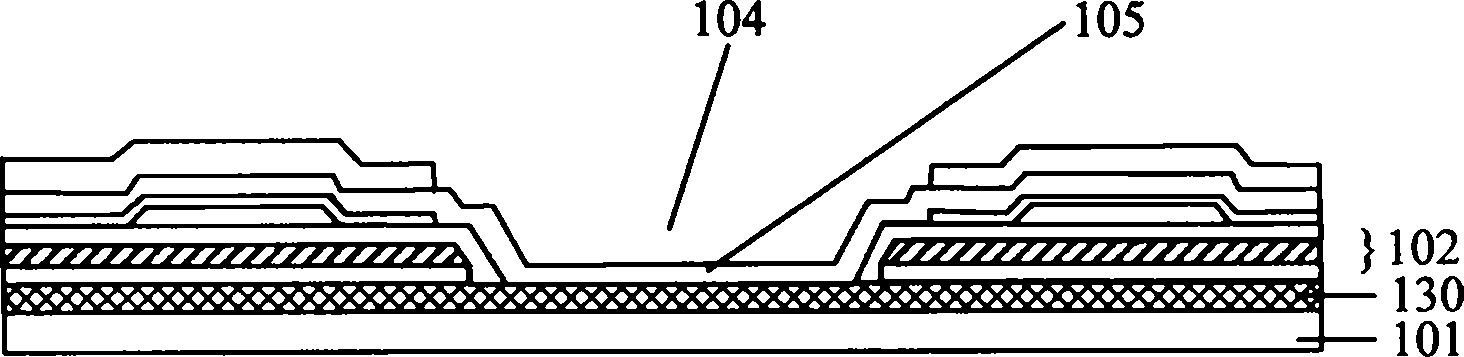

[0024] Such as figure 1 As shown, the LCD panel 100 to be described in detail in this embodiment includes a first substrate 101 and a plurality of separate and strip-shaped second substrates 102 fixed on the first substrate 101 . The second substrates 102 are equidistantly arranged side by side on the first substrate 101 . A pixel control unit 103 for display is also arranged on the second substrate 102 (refer to figure 2 ), since the size of the pixel control unit 103 is much smaller than the size of the first substrate 101 and the second substrate 102, in figure 1 Difficult to show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com