Preparation method and application of magnetic hydrotalcite/bismuth oxybromide compound

A magnetic hydrotalcite, bismuth oxybromide technology, applied in chemical instruments and methods, water pollutants, chemical/physical processes, etc., can solve the problems of long time required for catalysis, low recycling efficiency, and increased cost of catalyst application, Achieve fast electron hole separation efficiency and transfer speed, improve visible light catalytic activity, and good magnetic separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

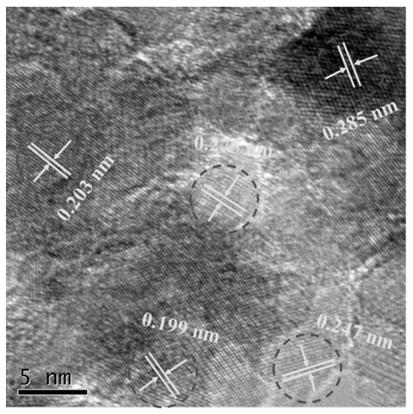

Image

Examples

preparation example Construction

[0058] The invention provides a method for preparing a magnetic hydrotalcite / bismuth oxybromide composite, comprising the following steps:

[0059] S1, preparation of zinc-aluminum hydrotalcite

[0060] Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is dissolved in distilled water to form a salt solution, NaOH and Na 2 CO 3 Dissolving in distilled water to form an alkaline solution, adding the salt solution and the alkaline solution dropwise into a container filled with distilled water at the same time, stirring, standing, washing with distilled water until neutral, drying, and grinding to obtain zinc-aluminum hydrotalcite;

[0061] S2, preparation of magnetic zinc-aluminum hydrotalcite:

[0062] FeCl 3 ·6H 2 O was dissolved in ethylene glycol, and NaAC·3H was added 2 O, stir, add anhydrous ethylenediammonium, stir, finally add zinc-aluminum hydrotalcite, stir, seal the obtained solution in a polytetrafluoroethylene reaction device, heat at 180-250°C for 6-20h, take out...

Embodiment 1

[0078] Preparation of Magnetic Hydrotalcite / Bismuth Oxybromide Composite:

[0079] S1, preparation of zinc aluminum hydrotalcite (ZnAl-LDH)

[0080] 8.93g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 5.83g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) dissolved in 100mL of distilled water to form a salt solution, 3.6g of sodium hydroxide (NaOH) and 2.82g of sodium carbonate (NaOH) 2 CO 3 ) is dissolved in 100mL of distilled water to form an alkaline solution, and simultaneously the salt solution and the alkaline solution are added dropwise to a three-necked flask filled with distilled water, the entire reaction temperature is controlled at 60°C and the rate of addition is controlled so that the pH value remains on 10, violently After stirring for 3 hours, leave it to age for 8 hours, wash with distilled water until neutral, dry in an oven at 60°C for 24 hours, grind it into powder after drying, and pass through a 100-mesh sieve to obtain zinc-aluminum hydrotalcite;

[0081] S2, prep...

Embodiment 2-5

[0089] Compared with Example 1, the preparation method of the magnetic hydrotalcite / bismuth oxybromide composite provided in Examples 2-5 is different in that in the S2 step: the zinc-aluminum hydrotalcite quality is 0.4, 0.6, 1.0 , 1.2g. Except for the above differences, other operations are basically the same and will not be repeated here.

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com