Magnetic silica porous adsorbent and preparation method and applications thereof

A porous adsorbent, silica technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of poor adsorption treatment selectivity, low adsorption efficiency, secondary Pollution and other problems, to achieve the effect of good selectivity, high reuse rate, cost and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

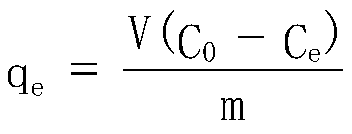

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a magnetic silicon dioxide porous adsorbent, comprising the steps of:

[0027] (1) Weigh 2.00g (0.005mol) Fe respectively 2 (SO 4 ) 3 , 1.20g (0.02mol) silica powder and 1.40g (0.005mol) FeSO 4 ·7H 2 O, whose molar concentration is higher than that of Fe 3+ :Fe 2+ :SiO2 2 =2:1:4. Fe first 2 (SO 4 ) 3 and silicon dioxide powder into 100ml of deionized water, ultrasonically dispersed for 10 minutes, then magnetically stirred until completely dissolved, the stirring temperature was 60°C, and then FeSO was added 4 ·7H 2 O was stirred for several minutes to completely dissolve the ferrous ions to obtain a mixed solution.

[0028] (2) Weigh 1.60 g of sodium hydroxide, dissolve it in 300 ml of deionized water, and control the temperature at 60° C., as the alkaline solution for the reaction.

[0029] (3) Slowly add the mixed solution in step 1 and the alkali solution in step 2, continue stirring after adding the mixed solution, adjust the pH...

Embodiment 2

[0035] A preparation method of a magnetic silicon dioxide porous adsorbent, comprising the steps of:

[0036] (1) Weigh 2.00g (0.005mol) Fe respectively 2 (SO 4 ) 3 , 1.20g (0.02mol) silica powder and 1.55g (0.0055mol) FeSO 4 ·7H 2 O, whose molar concentration is higher than that of Fe 3+ :Fe 2+ :SiO2 2 = 1.8:1:3.6. Fe 2 (SO 4 ) 3 and silicon dioxide powder into 100ml of deionized water, ultrasonically dispersed for 10min, then magnetically stirred until completely dissolved, the stirring temperature was 60°C, and then FeSO was added 4 ·7H 2 O was stirred for several minutes to completely dissolve the ferrous ions to obtain a mixed solution.

[0037] (2) Weigh 1.6 g of sodium hydroxide, dissolve it in 300 ml of deionized water, and control the temperature at 60° C., as the alkaline solution for the reaction.

[0038] (3) Slowly add the mixed solution in step 1 and the alkali solution in step 2, continue stirring after adding the mixed solution, adjust the pH to 11...

Embodiment 3

[0041] A preparation method of a magnetic silicon dioxide porous adsorbent, comprising the steps of:

[0042] (1) Weigh Fe respectively 2 (SO 4 ) 3 , silica powder and FeSO 4 ·7H 2 O, which is more molar than Fe 3+ :Fe 2+ :SiO2 2 =2:1:3. Fe 2 (SO 4 ) 3 Add silicon dioxide powder and 100ml deionized water, ultrasonically disperse for 10min, then magnetically stir until completely dissolved, stirring temperature is 70°C, then add FeSO 4 7H 2 O stirred for several minutes to completely dissolve the ferrous ions to obtain a mixed solution.

[0043] (2) Weigh 1.6 g of sodium hydroxide, dissolve it in 300 ml of deionized water, and control the temperature at 60° C., as the alkaline solution for the reaction.

[0044] (3) Slowly add the mixed solution in step 1 and the alkali solution in step 2, continue stirring after adding the mixed solution, heat, adjust the pH to 11, control the temperature at 70°C, react for 120 minutes, stop heating, After aging for 1 hour, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com