Method for preparing functional magnetic nano composite material

A magnetic nano-composite material technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of serious agglomeration, easy oxidation of particles, and reduced reactivity, and achieve uniform particle size distribution and particle size distribution. Uniform, simple-to-equip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

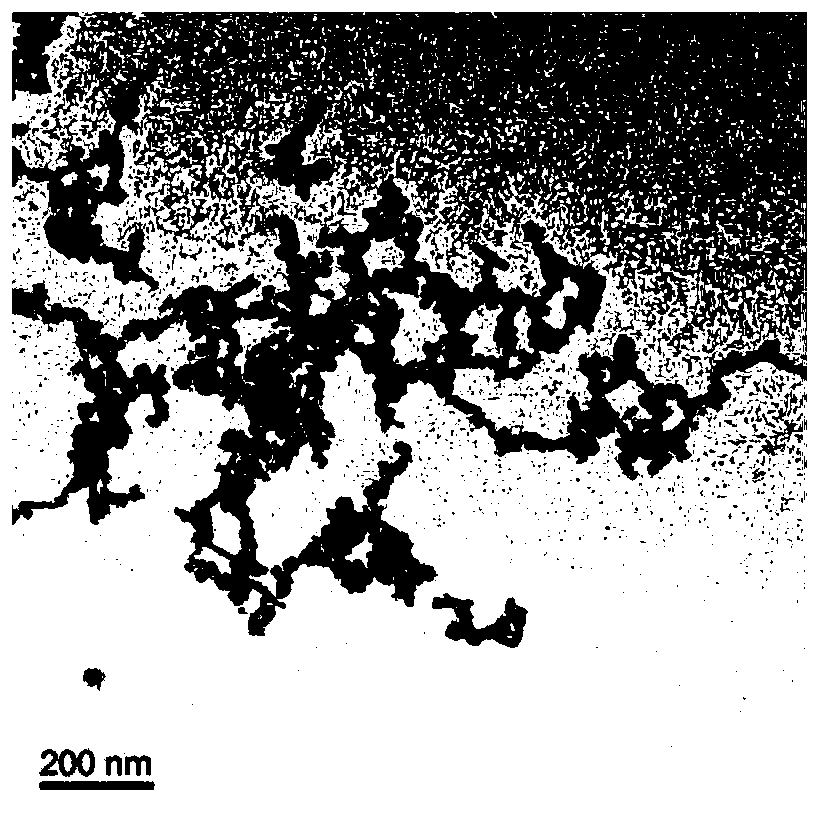

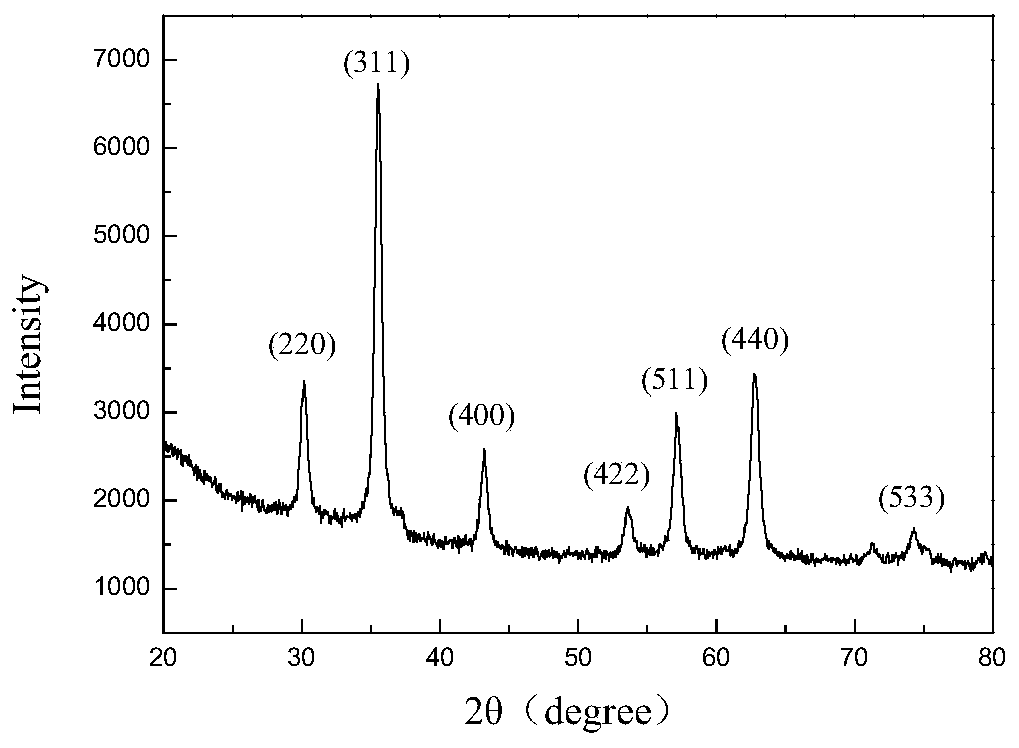

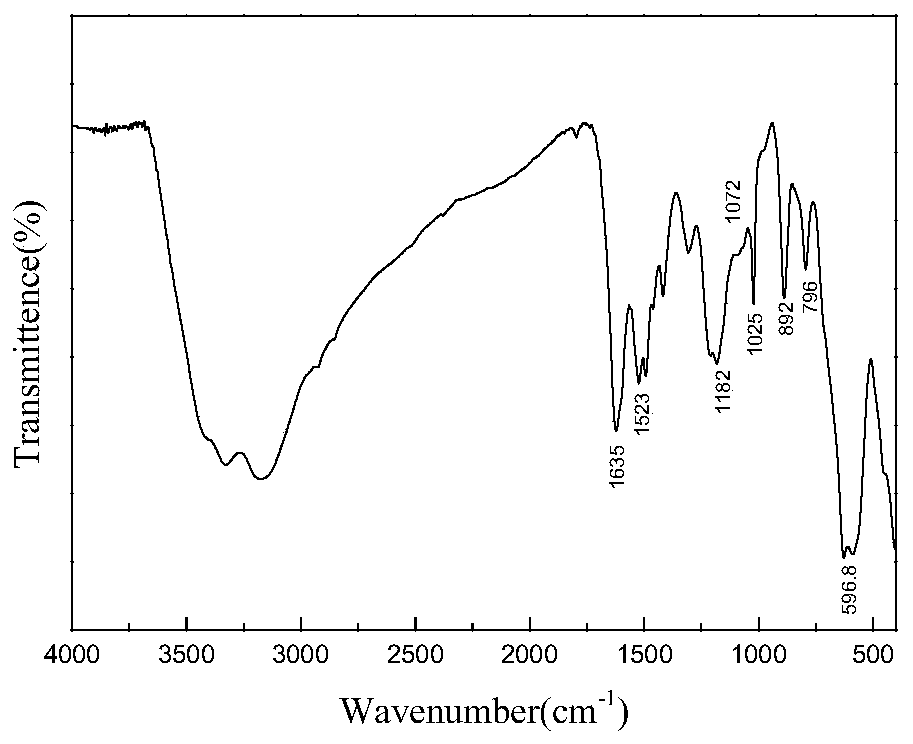

[0051] Under ultrasonic conditions (40KHz, 150W), to pass N 2 In the protected 250mL three-necked flask, FeSO was added in a molar ratio of 2:3. 4 ·7H 2 O 1.39g and FeCl 3 ·6H 2 Mix 2.03g of O with 100mL of oxygen-free deionized water, slowly drop into 1.0mol / L freshly prepared ammonia solution until the pH of the solution is 11, and stir for 1h in a water bath at 50°C. After the reaction was completed, it was washed with anaerobic deionized water (50mL×3), and vacuum-dried at 60°C for 12h to obtain magnetic nano-Fe 3 o 4 particles. Under ultrasonic condition (40KHz, 150W), take by weighing 0.5g (2.16mmol) the magnetic nanometer Fe that above-mentioned steps prepares 3 o 4 , 0.108g (1mmol) m-phenylenediamine monomer (mPD) and 0.188g (1mmol) 2,5-diaminobenzenesulfonic acid monomer (SP) were mixed in a 250mL three-neck flask, 100mL oxygen-free deionized water, and ultrasonically Disperse for 10min to obtain a solution; weigh 0.456g (2mmol) (NH 4 ) 2 S 2 o 8 Dissolve ...

Embodiment 2

[0059] Under ultrasonic conditions (40KHz, 150W), to pass N 2 In the protected 250mL three-necked flask, FeSO was added in a molar ratio of 2:3. 4 ·7H 2 O 1.39g and FeCl 3 ·6H 2 Mix 2.03g of O with 100mL of oxygen-free deionized water, slowly drop into 1.0mol / L freshly prepared ammonia solution until the pH of the solution is 11, and stir for 1h in a water bath at 50°C. After the reaction was completed, it was washed with anaerobic deionized water (50mL×3), and vacuum-dried at 60°C for 12h to obtain magnetic nano-Fe 3 o 4 particles. Under ultrasonic condition (40KHz, 150W), take by weighing 0.6g (2.59mmol) the magnetic nanometer Fe that above-mentioned steps prepares 3 o 4 , 0.108g (1mmol) m-phenylenediamine monomer (mPD) and 0.188g (1mmol) 2,5-diaminobenzenesulfonic acid monomer (SP) were mixed in a 250mL three-neck flask, 100mL oxygen-free deionized water, and ultrasonically Disperse for 10min to obtain a solution; weigh 0.456g (2mmol) (NH 4 ) 2 S 2 o 8 Dissolve ...

Embodiment 3

[0067] Under ultrasonic conditions (40KHz, 150W), to pass N 2 In the protected 250mL three-necked flask, FeSO was added in a molar ratio of 2:3. 4 ·7H 2 O 1.39g and FeCl 3 ·6H 2 Mix 2.03g of O with 100mL of oxygen-free deionized water, slowly drop into 1.0mol / L freshly prepared ammonia solution until the pH of the solution is 11, and stir for 1h in a water bath at 50°C. After the reaction was completed, it was washed with anaerobic deionized water (50mL×3), and vacuum-dried at 60°C for 12h to obtain magnetic nano-Fe 3 o 4 particles. Under ultrasonic condition (40KHz, 150W), take by weighing 0.5g (2.16mmol) the magnetic nanometer Fe that above-mentioned steps prepares 3 o 4 , 0.108g (1mmol) m-phenylenediamine monomer (mPD) and 0.188g (1mmol) 2,5-diaminobenzenesulfonic acid monomer (SP) were mixed in a 250mL three-neck flask, 100mL oxygen-free deionized water, and ultrasonically Disperse for 10min to obtain a solution; weigh 0.684g (3mmol) (NH 4 ) 2 S 2 o 8 Dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com