A kind of preparation method of ultra-sharp diamond wire saw and diamond wire saw

A diamond wire saw, ultra-sharp technology, applied in stone processing equipment, manufacturing tools, fine working devices, etc., can solve the problems of reducing the cutting force of the diamond wire, reducing the cutting force of the wire saw, and increasing the diameter of the diamond wire. The effect of reducing the wire diameter specification, increasing the roughness, and improving the cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

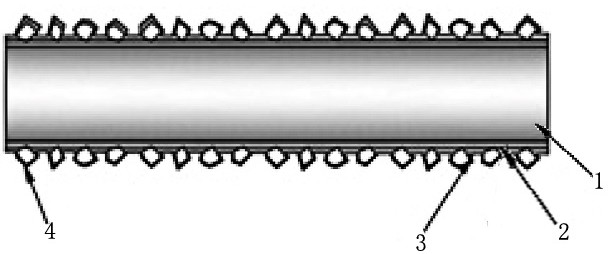

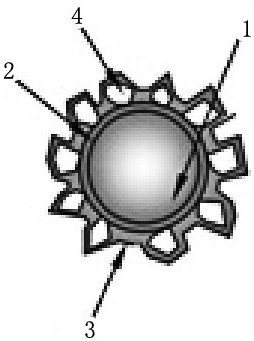

[0046] Example 1 Using the technical solution of the present invention, an ultra-sharp electroplated diamond wire with a specification of 66±2 μm was prepared, and the preparation process was as follows:

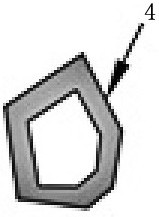

[0047] S1: Surface treatment of diamond: use nickel-plated diamond powder with D50=7.5, and its nickel weight gain is 30%; treat its surface, such as Figure 4 Therefore, the specific steps are as follows:

[0048]a: High-temperature sintering: put the nickel-plated diamond powder into a muffle furnace for 6 hours under normal pressure and high temperature at 1200°C, and then lower it to room temperature;

[0049] b: Deplating reaction: Put the diamond micropowder after high temperature sintering into water, the ratio is 100g diamond: 1L water, stir, and slowly add 100ml of concentrated sulfuric acid, 50ml of 30% hydrogen peroxide in order to carry out the deplating reaction, after the deplating is completed, then Wash it with pure water and dry it for later use.

[0050] ...

Embodiment 2

[0058] Example 2 Using the technical solution of the present invention, an ultra-sharp electroplated diamond wire with a specification of 72±2 μm was prepared. The preparation process is as follows:

[0059] S1: Surface treatment of diamond: select nickel-plated diamond powder with D50=8.0, and its nickel weight gain is 25%-50%; treat its surface, such as Figure 4 Therefore, the specific steps are as follows:

[0060] a: High-temperature sintering: put the nickel-plated diamond powder into a muffle furnace for 6 hours under normal pressure and high temperature at 1200°C, and then lower it to room temperature;

[0061] b: Deplating reaction: Put the diamond micropowder after high temperature sintering into water, the ratio is 100g diamond: 1L water, stir, and slowly add 100ml of concentrated sulfuric acid, 50ml of 30% hydrogen peroxide in order to carry out the deplating reaction, after the deplating is completed, then Wash it with pure water and dry it for later use.

[006...

Embodiment 3

[0070] Example 3 Using the technical solution of the present invention, an ultra-sharp electroplated diamond wire with a specification of 60±2 μm was prepared, and the preparation process was as follows:

[0071] S1: Surface treatment of diamond: select nickel-plated diamond powder with D50=6.5, and its nickel weight gain is 25%-50%; treat its surface, such as Figure 4 Therefore, the specific steps are as follows:

[0072] a: High-temperature sintering: put the nickel-plated diamond powder into a muffle furnace for 6 hours under normal pressure and high temperature at 1200°C, and then lower it to room temperature;

[0073] b: Deplating reaction: Put the diamond micropowder after high temperature sintering into water, the ratio is 100g diamond: 1L water, stir, and slowly add 100ml of concentrated sulfuric acid, 50ml of 30% hydrogen peroxide in order to carry out the deplating reaction, after the deplating is completed, then Wash it with pure water and dry it for later use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com