Acid etching solution

A technology of acid etching solution and nitric acid, which is applied in the field of etching solution, can solve the problems of high production cost and low amount of dissolved copper, and achieve the effects of reducing corrosion, increasing the amount of dissolved copper, and increasing the etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Simultaneously, the present invention also provides a kind of preparation method of laboratory acid etching solution, comprises the following steps:

[0026] Step 1) Take multiple dry and clean 250ML beakers on the workbench;

[0027] Step 2) Add 200ML stock solution to the beaker in step 1) (the stock solution was purchased from a large etching solution company in South China, and the stock solution contains hydrochloric acid, ammonium chloride and copper chloride);

[0028] Step 3) In the beaker where the original solution is added in step 2), add one or a combination of alkali metal salts, sulfamic acid, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium bicarbonate and amino One or a combination of sulfonic acid, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium bicarbonate;

[0029] Step 4) stirring and heating to 50° C. to obtain the final acidic etching solution.

[0030] In the above preparation method, the whole experi...

Embodiment

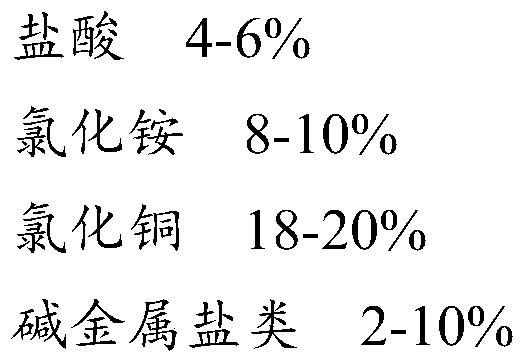

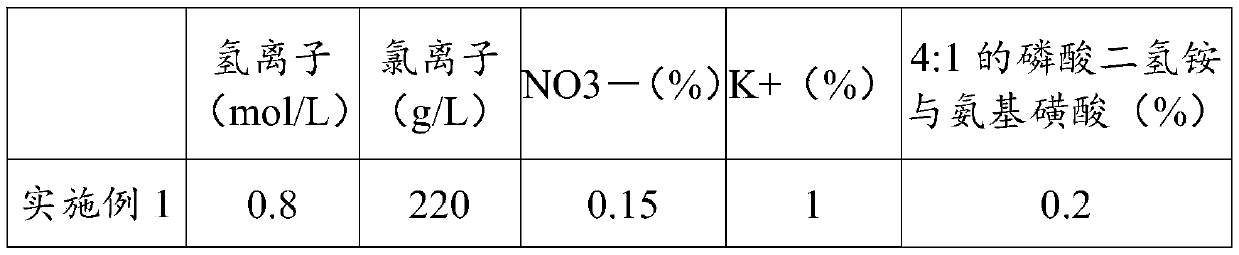

[0032] Embodiment is as follows: (wherein % represents: the mass percent of this material component in acidic etching solution)

[0033]

[0034]

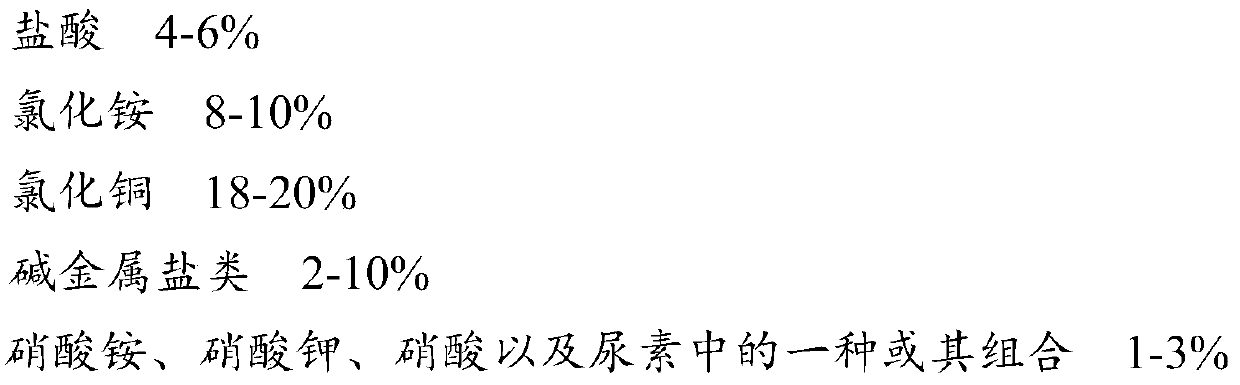

[0035] In the present embodiment group, select control group composition list as follows: (wherein % represents: the mass percent of this material component in acidic etching solution)

[0036]

[0037]

[0038] Wherein, the determination method of the amount of dissolved copper (unit: g / L) is: under the ammonia water-ammonium chloride environment of pH=10, it is measured by complexometric titration analysis of EDTA standard buffer solution, and the indicator is PAN.

[0039] The etching rate (unit: um / min) is:

[0040]

[0041] Among them, the mass unit before and after etching: g;

[0042] The etching area is the area of the etching rate slice, unit: cm2;

[0043] Etching time is the time when the etching rate sheet is in contact with the acidic etching solution, unit: min.

[0044] The etching result of using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com