A kind of production method of continuous hot-dip galvanized embossed sheet

A production method and technology for embossed plates, which are applied in hot-dip plating process, heat treatment furnace, heat treatment equipment, etc., can solve the problems of poor surface adhesion of plates, cumbersome galvanizing method, production line speed and production capacity constraints, etc., to avoid patterns The effect of different shades, maintaining surface finish and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

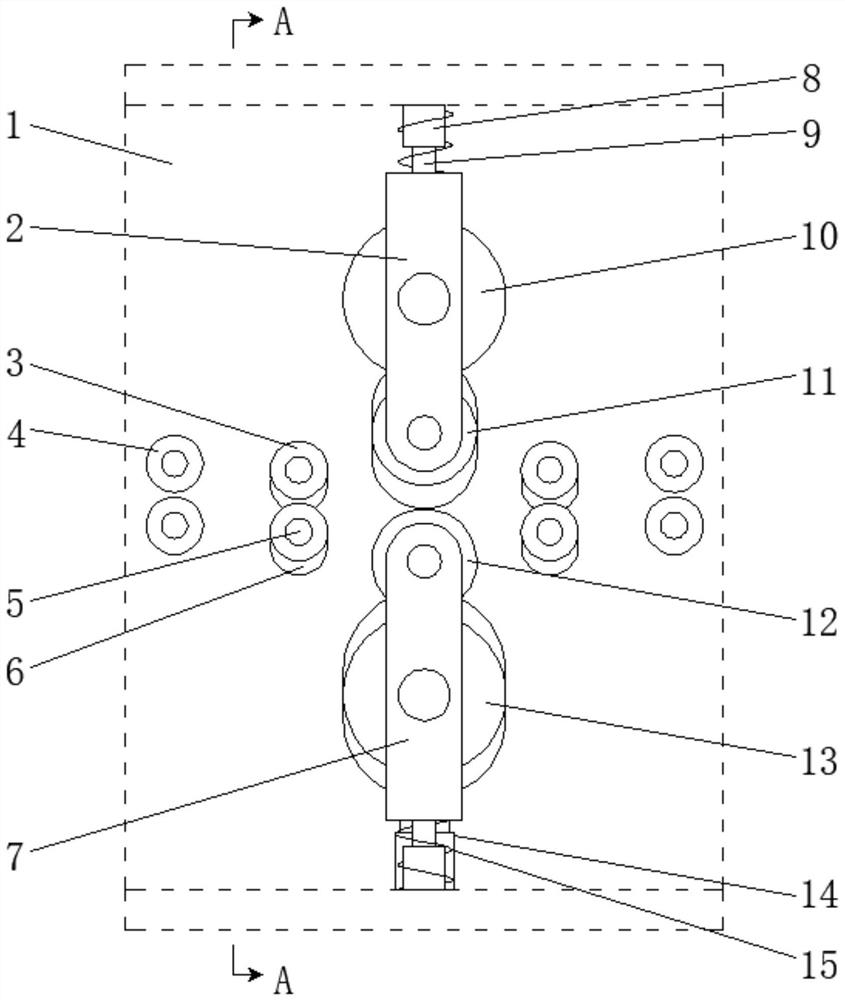

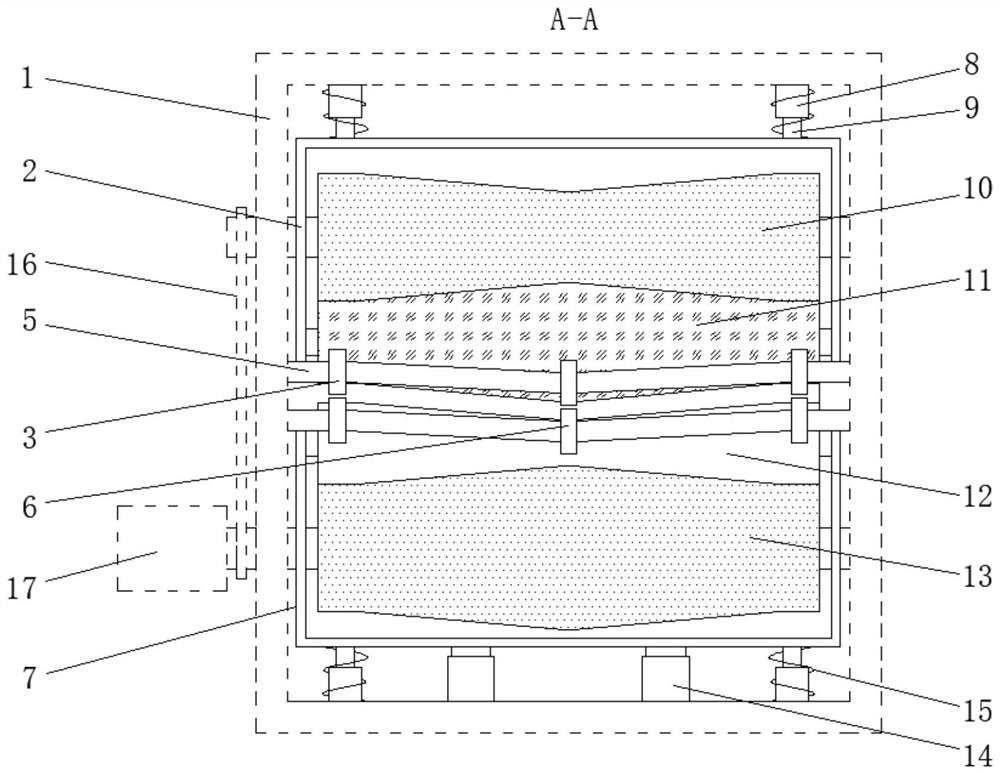

Image

Examples

Embodiment 1

[0033] A method for producing continuous hot-dip galvanized on-line embossed sheets, comprising the following steps:

[0034] Step 1: Alkali washing and degreasing: Spray hot lye with a temperature of 70°C on the strip surface after Kaiping, clean the oil stains, iron powder, and dust attachments on the strip surface with a brush, and then use a temperature of 60°C The hot water washes the surface of the strip to remove the lye remaining on the surface of the strip to obtain a clean strip after degreasing, and then immediately air-dry the surface of the clean strip after degreasing through a hot air dryer to effectively avoid water stains Residues to prevent the strip from being polluted and oxidized again after being wetted with water;

[0035] Step 2, annealing and reduction: use the preheating section to rapidly heat the clean strip steel obtained in step 1 to below 700°C, then fill the radiant tube section with H2 with a concentration of 10% as a protective gas, and reheat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com