Tert-butyl polyaryletherketone resin and preparation method thereof

The technology of tert-butyl polyaryl ether and tert-butyl aryl ether is applied in the field of tert-butyl polyaryl ether ketone resin and its preparation, and can solve the problems of high melting temperature and melt viscosity, difficult molding process, limited application and the like, Achieve the effects of excellent solubility and film-forming properties, good heat resistance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of tert-butyl aryl ether monomer

[0048] Add 0.22mol o-tert-butylphenol, 50ml N-methylpyrrolidone, 0.22mol sodium hydroxide, and 80ml toluene to a three-necked flask equipped with a mechanical stirrer, reflux dehydration device, and nitrogen protection. Heating under reflux for dehydration, until the reaction is complete to remove the water, the temperature of the oil bath is raised to 160°C to distill the toluene. Cool slightly, add 0.1mol of 4,4-dichlorobenzophenone, and adjust the temperature of the oil bath to 190-200°C, and react for 5-6h. After the reaction was completed, the reactant was poured into water to precipitate a precipitate, filtered with suction, washed once with dilute sodium hydroxide solution, and washed once with cold and hot water to obtain a solid with a yield of 90%. The prepared monomers were recrystallized, dried and characterized for structure.

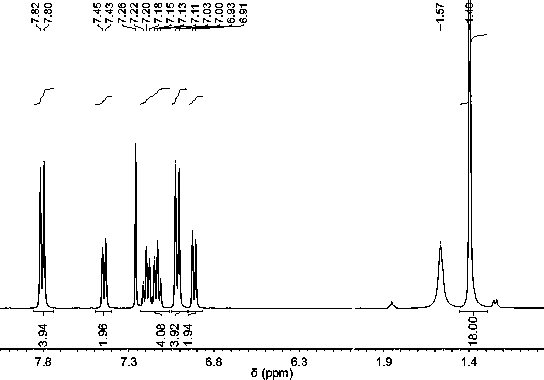

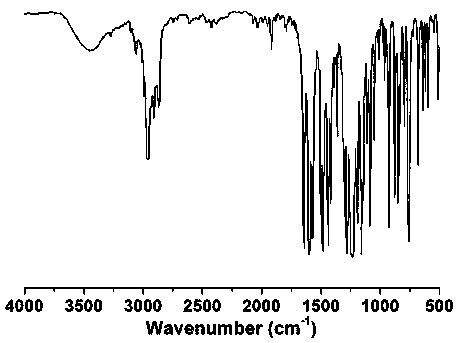

[0049] From figure 1 The H NMR spectrum is given. 1 H NMR (400MHz, CDCl 3 )δ 7....

Embodiment 2

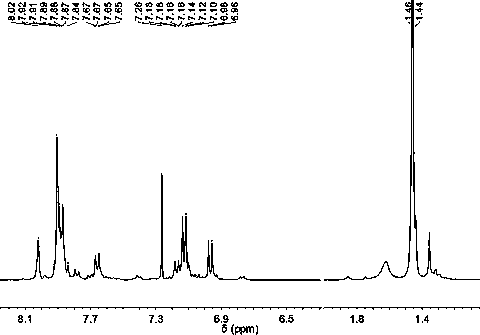

[0051] Add 0.22mol o-tert-butylphenol, 50ml sulfolane, 0.22mol potassium carbonate, and 80ml toluene to a three-necked flask equipped with a mechanical stirrer, reflux dehydration device, and nitrogen protection, and heat the mixture under reflux dehydration at a temperature of 150°C in an oil bath. After the reaction was completed, the water was removed, and the temperature of the oil bath was raised to 160°C to distill off the toluene. Cool slightly, add 0.1mol of 4,4'-difluorobenzophenone, and adjust the temperature of the oil bath to 200°C, and react for 5-6h. After the reaction was completed, the reactant was poured into water to precipitate a precipitate, filtered with suction, washed once with dilute sodium hydroxide solution, and washed once with cold and hot water to obtain a solid with a yield of 95%. The prepared tert-butyl aryl ether monomer was recrystallized and dried to characterize the structure.

Embodiment 3

[0053] Add 0.22mol o-tert-butylphenol, 50ml N-methylpyrrolidone, 0.22mol potassium hydroxide, and 80ml toluene to a three-necked flask equipped with a mechanical stirrer, reflux dehydration device, and nitrogen protection. Heating under reflux for dehydration, until the reaction is complete to remove the water, the temperature of the oil bath is raised to 160°C to distill the toluene. Cool slightly, add 0.1mol of 1,4-bis(4-fluorobenzoyl)benzene, and adjust the temperature of the oil bath to 180-190°C, and react for 5-6h. After the reaction was completed, the reactant was poured into water to precipitate a precipitate, filtered with suction, washed once with dilute sodium hydroxide solution, and washed once with cold and hot water to obtain a solid with a yield of 96%. The prepared tert-butyl aryl ether monomer was recrystallized and dried to characterize the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com