Solid waste disposal process

A solid waste and treatment technology technology, applied in the field of solid waste treatment technology, can solve the problems of resource waste, secondary pollution, long treatment cycle, etc., and achieve high recovery rate, less NOX generation and low treatment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

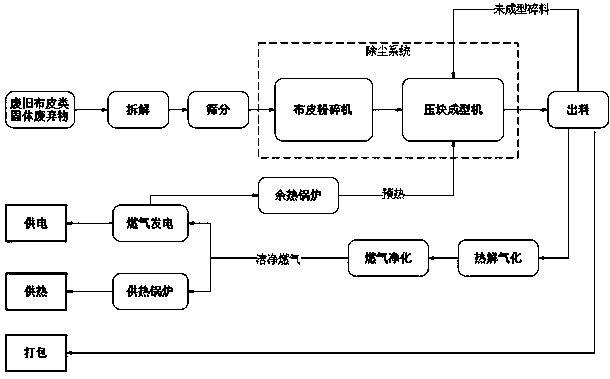

[0022] Such as figure 1 As shown, the present invention discloses a process for energy utilization and treatment of solid waste based on briquette fuel and pyrolysis gasification technology as the core, and its inventive concept is as follows.

[0023] (1) Preprocessing stage.

[0024] The pretreatment stage mainly includes two units of dismantling and screening.

[0025] Solid waste includes, but is not limited to, waste cloth and leather materials on large pieces of furniture, cloth and leather materials used in the production of clothes and leather bags, and other bulk materials such as cloth, leather, and cloth and leather composite materials. Therefore, for the waste raw materials of non-pure cloth and leather, it needs to be processed by dismantling unit, and the waste cloth and leather are disassembled from other metal or wood materials on large furniture, so as to achieve the purpose of separation and facilitate subsequent targeted Processing to avoid the impact of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com