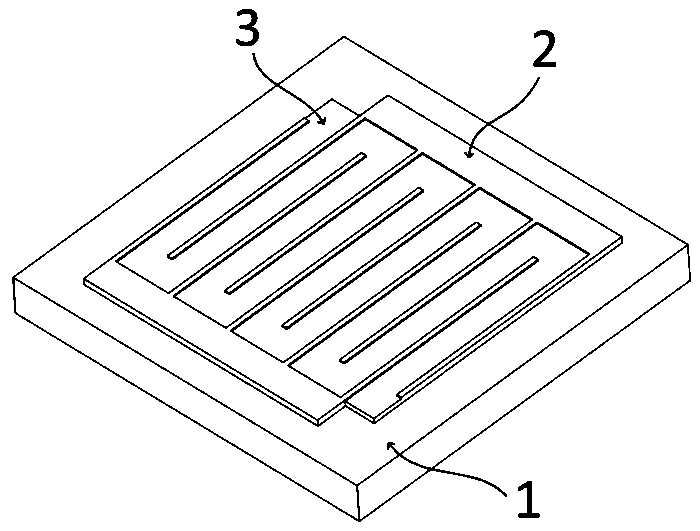

A selenide nanorod, its preparation method and its prepared photodetector

A nanorod and selenide technology, applied in nanotechnology, photovoltaic power generation, nanotechnology, etc., can solve the problems of low thermoelectric power factor, detector spectral responsivity, low external quantum efficiency, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of selenide nanorods: 20g of KOH, 5mmol of SeO 2 powder, 0.1mmol AgNO 3 and 4.9 mmol of dried In(NO 3 ) 3 ▪4H 2 O is put into a stainless steel reaction kettle lined with polytetrafluoroethylene, mechanically stirred, and the reactants are fully mixed, then 10ml of 1-octadecene and 0.2ml of ethylenediamine are added to the reaction vessel, under the protection of argon , heat up to 80-100°C, and use ultrasonic stirring until the solids are completely dissolved; then, under the protection of argon, continue to heat up to 200-240°C, and use a magnetic stirrer to stir vigorously, and keep it warm for 12 hours; wait for it to cool to room temperature Afterwards, the nanorod products were collected.

[0040] Impurity removal of selenide nanorods: Dissolve the product with deionized water, wash it, and then use dilute hydrochloric acid to adjust and remove potassium hydroxide on the surface of the product, and then continue to use deionized water to clean; the...

Embodiment 2

[0044] Preparation of selenide nanorods: 20g of KOH, 5mmol of SeO2 powder, 0.1mmol of AgNO3 and 4.9mmol of dried In(NO3)3 4H2O were dropped into a stainless steel reaction kettle lined with polytetrafluoroethylene. Stir mechanically to mix the reactants thoroughly, then add 5ml of deionized water and 0.1ml of ethylenediamine to the reaction vessel, under the protection of argon, raise the temperature to 80-100°C, and use ultrasonic stirring until all the solids are dissolved; Then, under the protection of argon, continue to heat up to 200-240° C., stir vigorously with a magnetic stirrer, and keep the temperature for 12 hours; after it is cooled to room temperature, the nanorod product is collected.

[0045] Impurity removal of selenide nanorods: Dissolve the product with deionized water, wash it, and then use dilute hydrochloric acid to adjust and remove potassium hydroxide on the surface of the product, and then continue to use deionized water to clean; then add the cleaned pr...

Embodiment 3

[0049] Preparation of selenide nanorods: 20g of KOH, 5mmol of SeO 2 powder and 5mmol of dried In(NO 3 ) 3 ▪4H 2 O is put into a stainless steel reaction kettle lined with polytetrafluoroethylene, mechanically stirred, and the reactants are fully mixed, then 10ml of 1-octadecene and 0.2ml of ethylenediamine are added to the reaction vessel, under the protection of argon , heat up to 80-100°C, and use ultrasonic stirring until the solids are completely dissolved; then, under the protection of argon, continue to heat up to 200-240°C, and use a magnetic stirrer to stir vigorously, and keep it warm for 12 hours; wait for it to cool to room temperature Afterwards, the nanorod products were collected.

[0050] Impurity removal of selenide nanorods: Dissolve the product with deionized water, wash it, and then use dilute hydrochloric acid to adjust and remove potassium hydroxide on the surface of the product, and then continue to use deionized water to clean; then add the cleaned pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com