Heat shield for stove and stove using heat shield

A technology for heat shields and stoves, applied in the field of stoves, can solve the problems of high exhaust gas emission and insufficient combustion, and achieve the effects of reducing pollution, saving energy, and avoiding the mutual influence of secondary air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

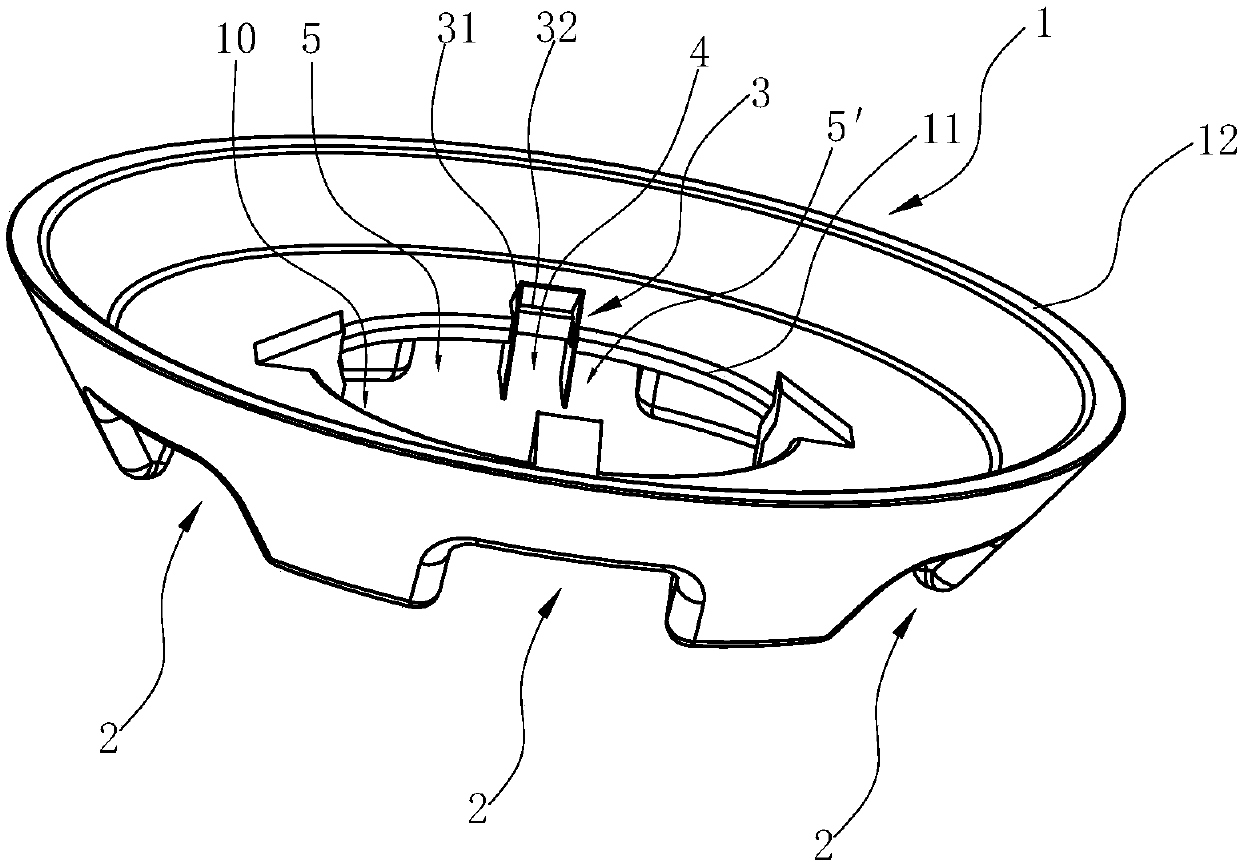

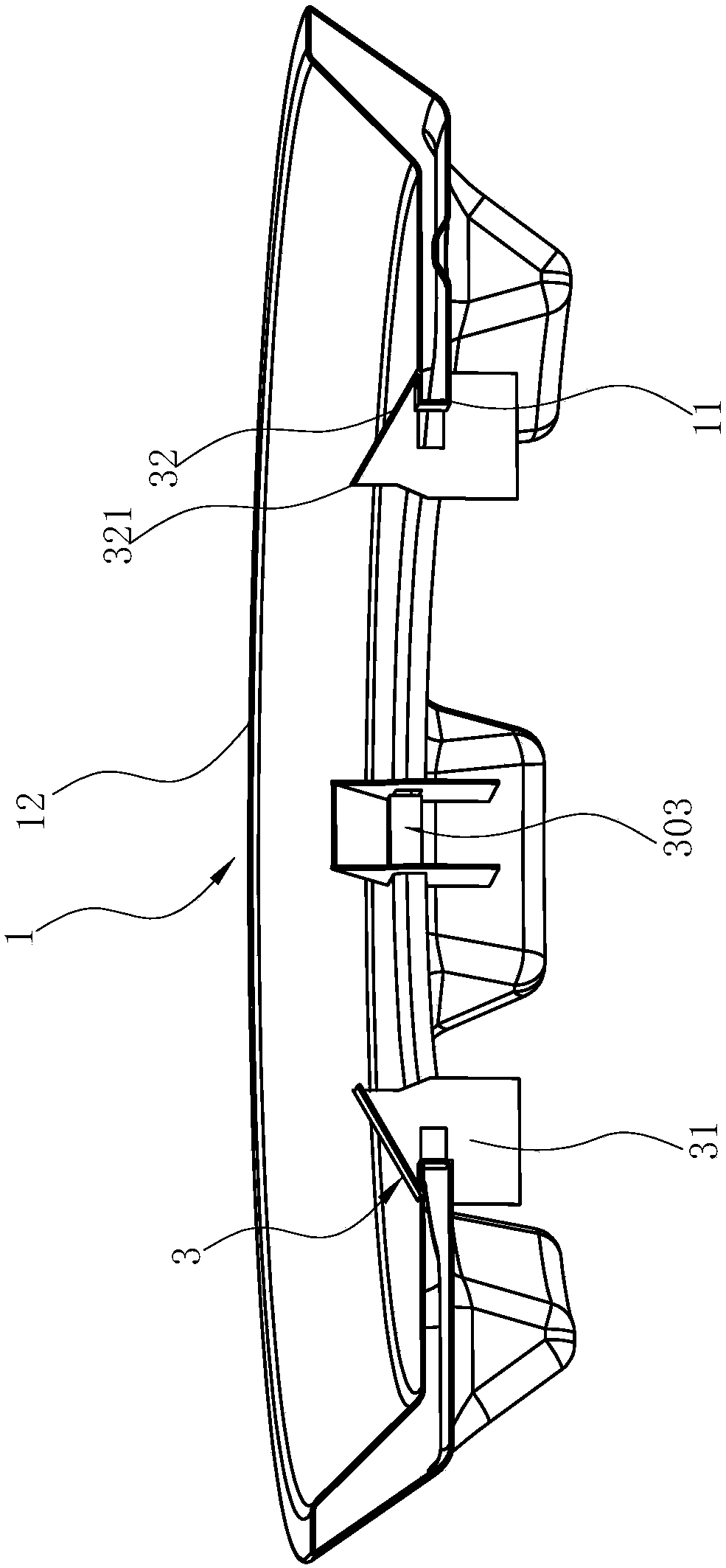

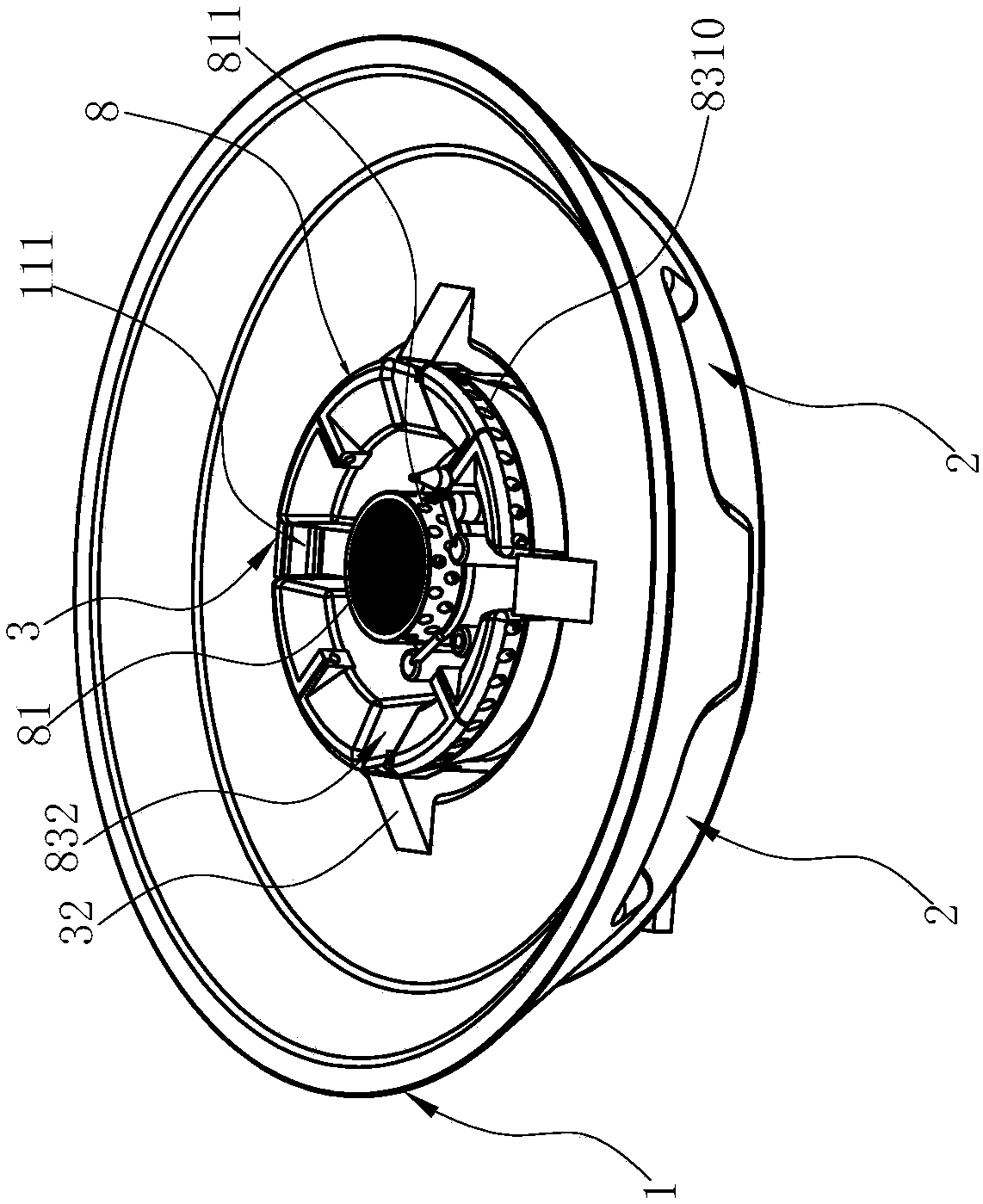

[0022] Such as figure 1 and 2 As shown, it is the best implementation mode of the present invention. The heat shield for the stove in this embodiment includes an annular cover body 1, a cavity 10 is formed in the center of the cover body 1, and the inner edge 11 of the cover body 1 is low in height. At the height of the outer edge 12, in order to better block the heat of the cooker panel 6, the inner edge 11 of the cover body 1 extends inward to form a platform that can fit with the cooker panel 6, so as to form a large upper port and a smaller lower port. Bowl-shaped cover body 1, the cover body 1 has a sandwich 13 structure, the interlayer 13 is evacuated or filled with heat insulating material to prevent or reduce the heat loss of the flame, the interlayer 13 is a heat storage component, which can form an effective energy-saving device, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com