A kind of composite coating, preparation method and application

A composite coating and composite wire technology, applied in the coating, metal material coating process, etc., can solve the difficulty of feeding tiny hard phase particles, uneven distribution of hard phase particles, and limited size of hard phase particles and other problems, to achieve the effect of widening the scope of use, small microstructure, and solving feeding difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

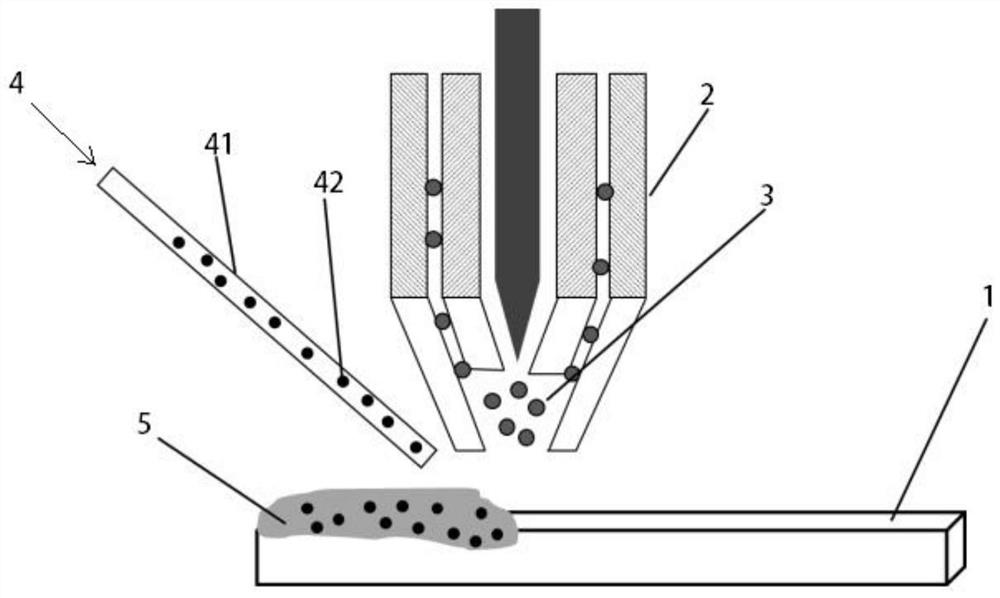

[0076] Such as figure 1 Shown, the invention provides a kind of preparation method of composite coating, comprises the following steps:

[0077] S1, preparing composite wire 4;

[0078] Select non-spherical titanium nitride hard phase particles with an average particle size of 5 μm as the strengthening phase, select 3Cr13 stainless steel as the base material, use the base material as the outer skin 41, and use the hard phase particles as the inner core 42 to prepare a composite material with a diameter of 0.5 mm. wire4;

[0079] S2, plasma cladding

[0080] No. 45 carbon steel is selected as the base material 1 of plasma cladding, and 3Cr13 stainless steel powder is selected as the basic powder material 3, with an average particle size of 53 μm;

[0081] The relevant parameters for setting plasma cladding are: ion air flow is 5L / min, protective air flow is 3L / min, powder feeding air flow rate for basic powder material is 5L / min, cladding current is 60A, powder feeding speed...

Embodiment 2

[0089]The difference from Example 1 is that the hard phase particles in this embodiment are non-spherical niobium carbide with an average particle diameter of 3 μm; the base material is 440A stainless steel, the base powder material is 440A stainless steel powder, and the average particle diameter of the powder is 105 μm; Material 1 is 2Cr13 stainless steel; The diameter of the prepared composite wire is 0.4mm, adopts the method identical with embodiment 1, is 10 degrees with the angle between lateral wire feeding direction and plasma cladding nozzle 2 axes, The composite wire 4 is fed into the molten pool for melting to obtain the composite coating 5 .

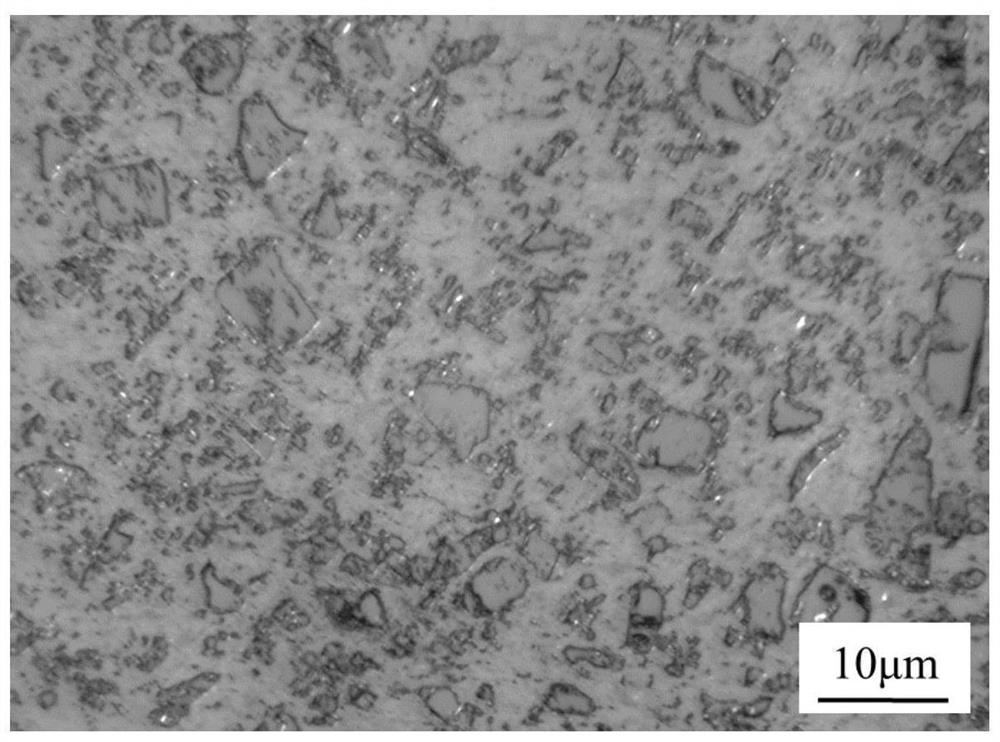

[0090] The test results of the composite coating 5 sample show that the composite coating 5 has no cracks on the surface, the average Rockwell hardness is 66HRC, the wear amount is 28mg, and the friction coefficient is 0.31. Such as Figure 3A As shown, it can be clearly seen that the hard phase particles of niobium carbide ...

Embodiment 3

[0092] The difference from Example 1 is that the hard phase particles in this example are non-spherical niobium diboride with an average particle size of 0.1 μm, the base material is 304 stainless steel, the base powder material is 304 stainless steel powder, and the average particle size is 80 μm ; Base material 1 is 304 stainless steel; The diameter of the prepared composite wire is 0.7mm, adopts the method identical with embodiment 1, is 80 with the angle between lateral wire feeding direction and plasma cladding nozzle 2 axes The composite coating 5 can be obtained by feeding the composite wire 4 into the molten pool for melting.

[0093] The test results of the composite coating 5 sample show that the composite coating 5 has no cracks on the surface, the average Rockwell hardness is 67HRC, the wear amount is 27mg, and the friction coefficient is 0.32. Such as Figure 4A As shown, it can be clearly seen that the hard phase particles of niobium diboride are evenly distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com