Neodymium iron boron-PPS plastic magnetic material with high fluidity and high magnetic properties, and preparation method thereof

A technology of NdFeB and plastic magnetism, which is applied in the field of NdFeB PPS plastic magnetic material with high fluidity and high magnetic properties and its preparation field, which can solve the problems of reduced fluidity, influence on magnetic properties, poor fluidity, etc., and achieve processing time Appropriateness, reduced oxidation problems, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing the neodymium-iron-boron PPS plastic-magnetic material described in the above technical solution, comprising the following steps:

[0030] mixing NdFeB magnetic powder, a solvent and a silane coupling agent, and first modifying the NdFeB magnetic powder to obtain a first modified mixture;

[0031] mixing the first modified mixture with a lubricating dispersant, an antioxidant and EEA, and performing a second modification to obtain a second modified mixture;

[0032] The second modified mixture is kneaded with PPS and extruded to obtain NdFeB PPS plastic magnetic material.

[0033] The invention mixes NdFeB magnetic powder, solvent and silane coupling agent, performs first modification on NdFeB magnetic powder, and obtains first modified mixed material. In the present invention, the solvent is preferably absolute ethanol, and the liquid-solid ratio of the absolute ethanol to the NdFeB magnetic powder is preferably 25...

Embodiment 1~7

[0043] (1) Magnetic powder and PPS pretreatment

[0044] Use NdFeB magnetic powder with the brand name MQP-A-10179, put it into a PH-050A constant temperature drying oven and dry it at 120°C for 30min;

[0045] Use the PPS resin with the brand name of 0220A9 and place it in a PH-050A constant temperature drying oven, dry at 120°C for 3 hours, and dry at 60°C for 12 hours;

[0046] (2) Mixing process

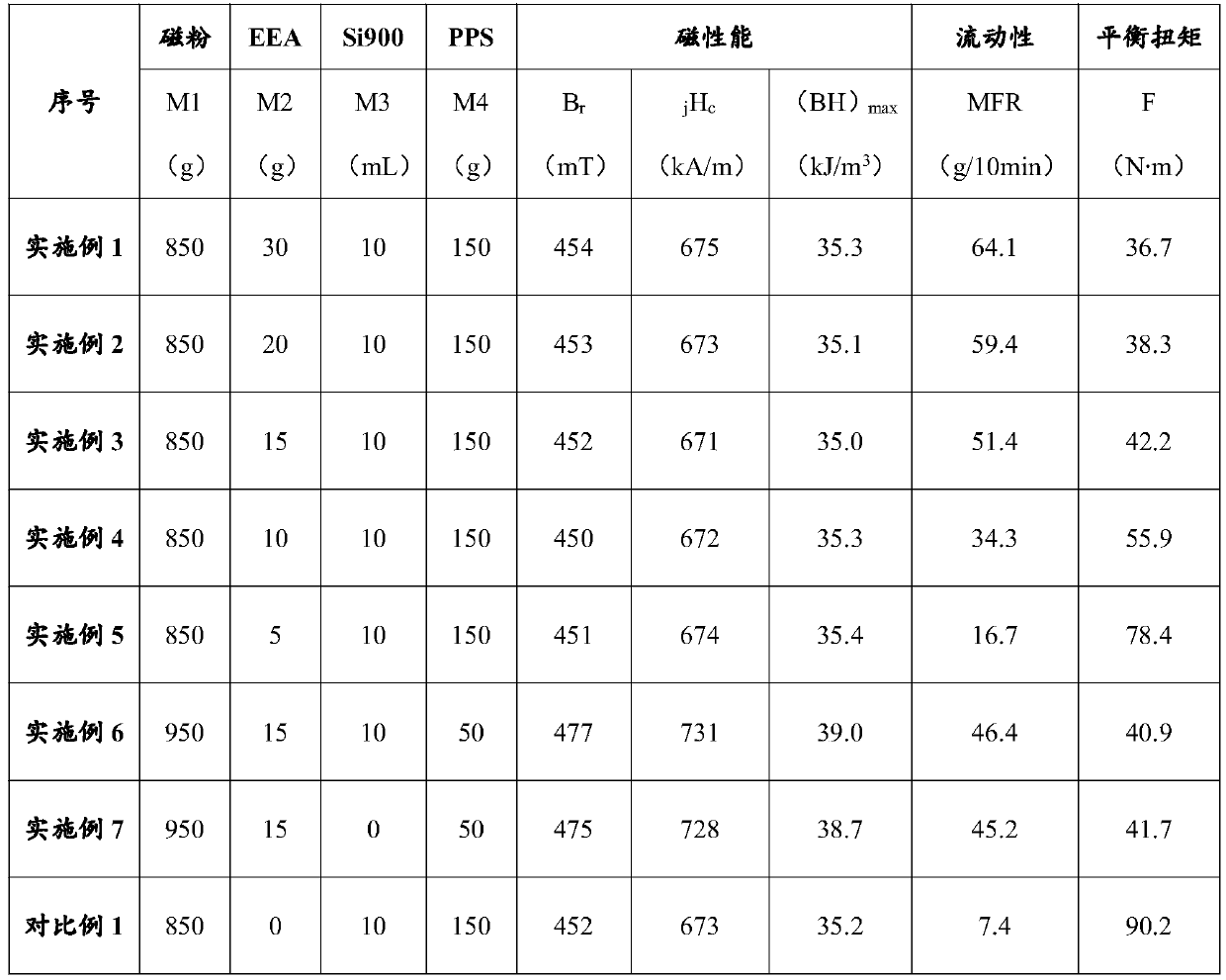

[0047] According to the formula in Table 1, set the filling amount of NdFeB magnetic powder, the mass is M1, add 25mL of absolute ethanol, add the coupling agent SG-Si900 with the mass of M3, use XJD-300B high-speed mixer to mix at high speed for 1.5min, and obtain the first modification After the material is discharged, the tank is thoroughly cleaned; then add 2 g of TAF lubricating and dispersing agent, 0.3 g of BASF Ciba 168 quality, add EEA (mass is M2), and mix at high speed for 1.5 minutes to obtain the second modified mixture.

[0048] (3) Material drying

[0049] Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com