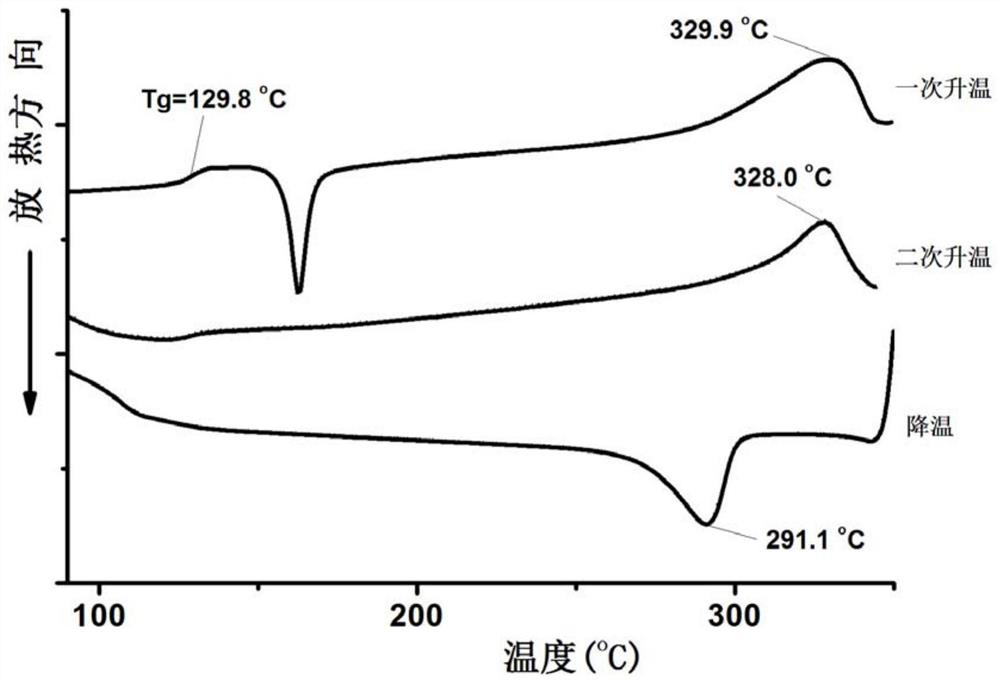

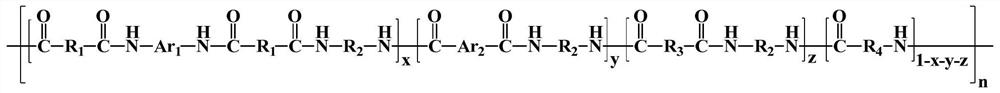

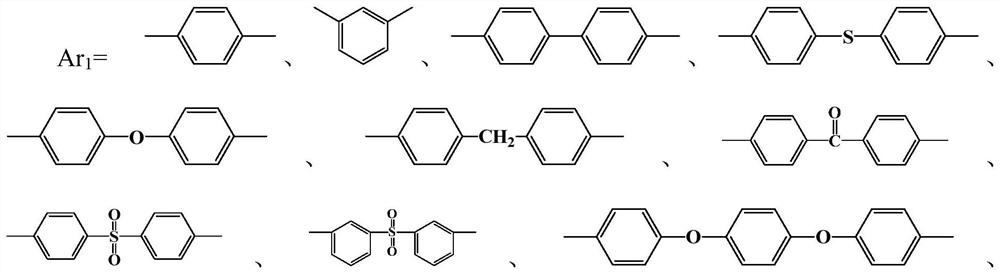

A semi-aromatic polyamide based on aromatic diamine and preparation method thereof

A technology of aromatic dibasic and aromatic dibasic acids, which is applied in the field of polymer synthesis, can solve problems such as poor melt fluidity and decreased crystallinity, and achieve high continuous use temperature, low water absorption, and good high-temperature rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Add 2000g of succinic anhydride and 3000g of N-methyl-2-pyrrolidone into a reactor equipped with a stirrer, a thermometer, a condenser tube and a nitrogen inlet and outlet tube; under the protection of nitrogen, add 1080g of p-phenylenediamine, and stir the reaction at room temperature The reaction solution was obtained in 5 hours; the reaction solution was added to 0.10 mol / L hydrochloric acid to precipitate the product, which was filtered, washed, and dried in a vacuum oven at 80°C for 24 hours to obtain the monomer.

[0073]Add 1540g of the above-mentioned monomers, 830g of terephthalic acid, 1280g of hexamethylenediamine, 226g of caprolactam, 50g of phosphoric acid, 80g of stearic acid and 3500g of deionized water into the reactor, and raise the temperature to 95°C within 1 hour under the protection of nitrogen; Close the reaction kettle, raise the temperature to 240°C within 2 hours, and react for 4 hours; cool down and discharge, the solid is crushed and dried to a...

Embodiment 2

[0076] Add 228g of glutaric anhydride and 800g of 1,3-dimethyl-2-imidazolidinone into a reactor equipped with a stirrer, thermometer, condenser and nitrogen inlet and outlet tubes; under nitrogen protection, add 216g of 4,4 '-Diaminodiphenyl sulfide, stirred and reacted at room temperature for 4 hours; the reaction solution was added to water to precipitate the product, filtered, washed, and dried in a vacuum oven at 80°C for 24 hours to obtain the monomer.

[0077] 333g of the above monomers, 43g of 2,5-thiophenedicarboxylic acid, 68.5g of 4,4'-dicarboxydiphenyl sulfide, 139g of pentamethylenediamine, 2g of sodium hypophosphite, 5g of p-toluic acid and 200g of deionized water Put it into the reaction kettle, under the protection of nitrogen, raise the temperature to 100°C within 0.5h; close the reaction kettle, raise the temperature to 230°C within 1h, and react for 5h; cool down and discharge, the solid is crushed and dried until the water content is ≤0.3%. A semiaromatic po...

Embodiment 3

[0080] Add 1,000g of succinic anhydride and 2,500g of N,N-dimethylacetamide into a reactor equipped with a stirrer, a thermometer, a condenser tube, and nitrogen inlet and outlet tubes; under nitrogen protection, add 1,240g of 4,4'-diamino Diphenyl sulfone was reacted with stirring at room temperature for 6 hours; the reaction solution was added into water to precipitate the product, which was filtered, washed, and dried in a vacuum oven at 80°C for 24 hours to obtain the monomer.

[0081] 1344g of the above monomers, 522g of 4,4'-bis(4-carboxyphenylthio)diphenylsulfone, 585g of p-xylylenediamine, 201g of 11-aminoundecanoic acid, 10g of polyphosphoric acid, 5g of sodium triphosphate, 25g of sodium formate and 1100g of deionized water were added to the reaction kettle, and under the protection of nitrogen, the temperature was raised to 90°C within 1 hour; the reaction kettle was closed, and the temperature was raised to 260°C within 3 hours, and the reaction was carried out for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com