Process for high precision control of welding deformation

A technology of welding deformation and process method, used in manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of inability to process the trunnion at one time, difficult to ensure the coaxiality of the trunnion, and large size, and achieve good rigidity and strength. , the effect of ensuring accuracy requirements and reducing the possibility of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

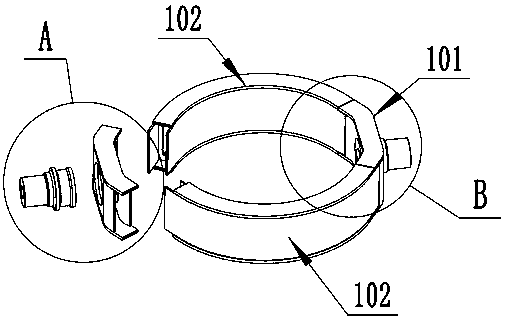

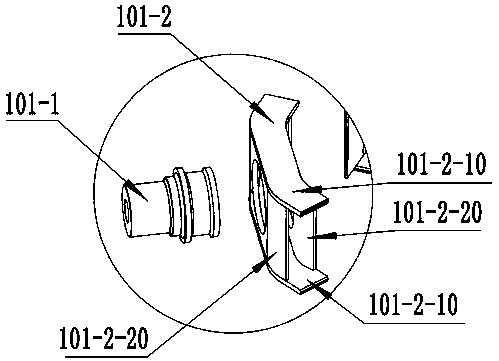

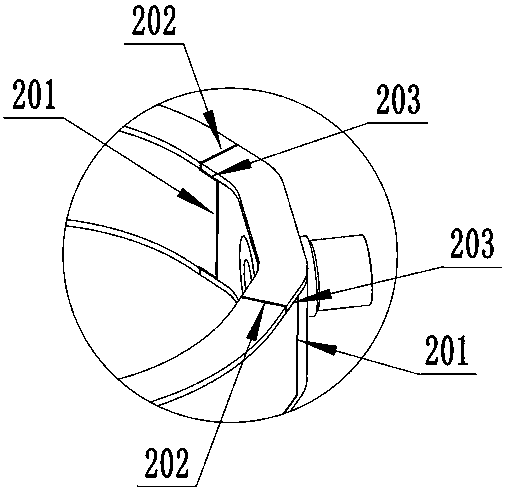

[0052] First introduce the made support ring: such as Figures 1 to 3 , the maximum diameter of the support ring is Φ8.5m; the height of the fan-shaped block 102 is 2m, the width of the box is 0.6m, the thickness of the upper and lower cover plates of the box is 100mm, and the thickness of the arc-shaped side plate is 60mm; the diameter of the trunnion after finishing is Φ0 .9m, length 1.8m; total weight over 50 tons. The coaxiality of the trunnion is required to be ≤Φ1mm, and the flatness of the support ring is required to be ≤3mm.

[0053] The implementation steps are as follows:

[0054] (A) Preparatory stage:

[0055] 1. The upper and lower cover plates and side plates of the trunnion block and the sector block 102 are blanked and prefabricated according to the process requirements.

[0056] 2. Complete the pairing and welding of the fan-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com