Cyclone for nozzle

A swirler and nozzle technology, which is applied in the field of swirlers for nozzles, can solve the problems of affecting the stability of the combustion process, the poor uniformity of the atomization degree in the circumferential direction, the instability of the spray flow rate of the nozzle and the angle of the fog cone, etc., so as to save rare Metal resources, reduced erosion, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

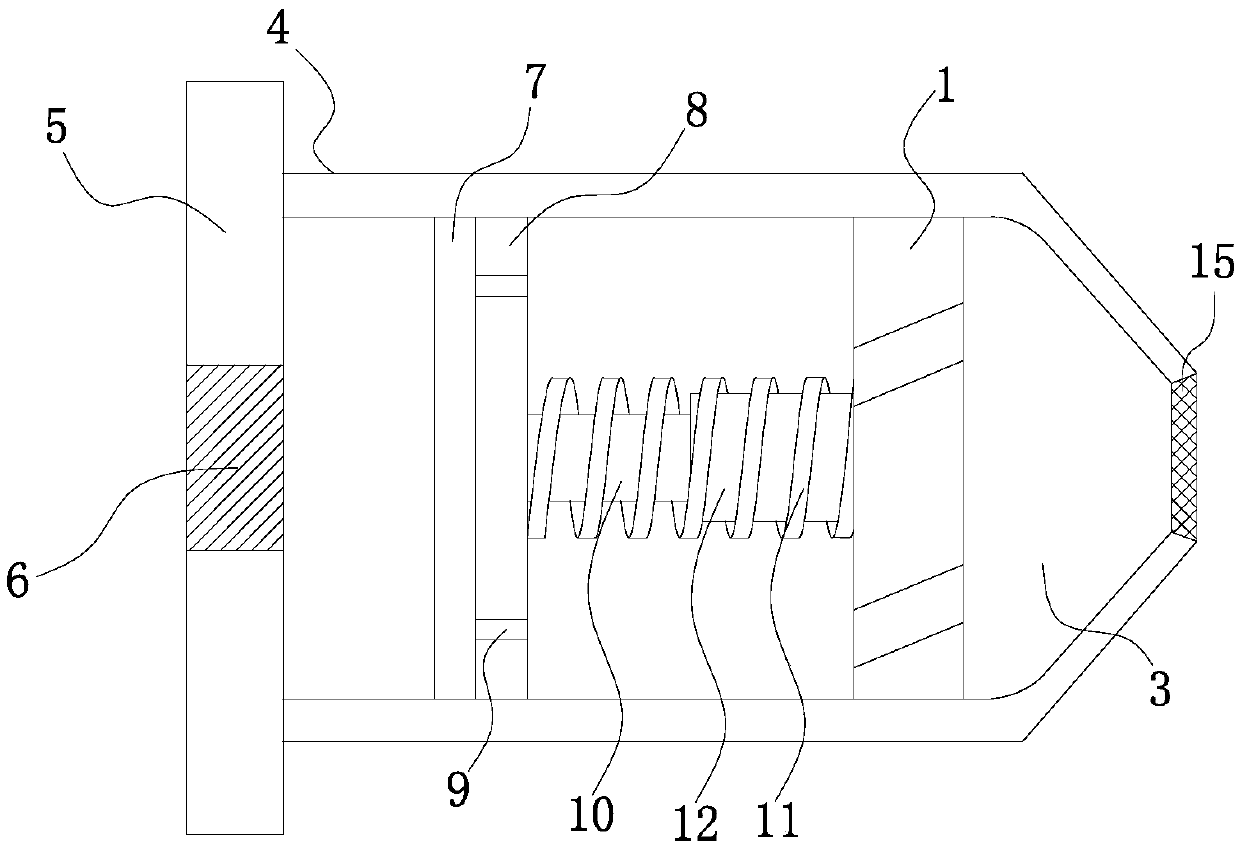

[0024] Such as Figure 1-4 As shown, when the material of the cyclone body 1 is a metal material, the hardness of the metal material is lower than that of the ceramic material. It is easy to change the size and even the structure of the swirl channel 2 during service. This situation is more obvious under high-pressure conditions, which will affect the injection flow rate of the nozzle 3 and the instability of the mist cone angle, which will affect the stability of the combustion process. The completed swirler body 1 replaces the application of the superalloy to the swirler in the conventional nozzle 3, saving rare metal resources.

Embodiment 2

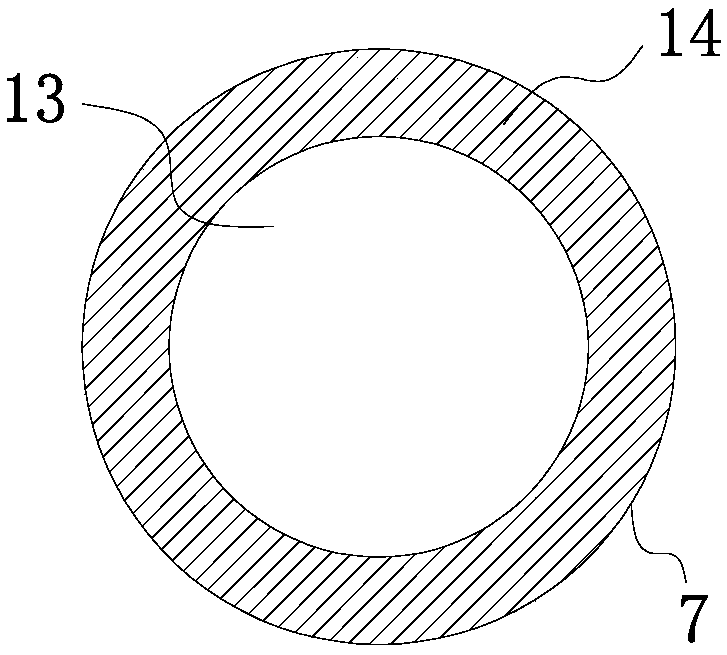

[0026] Such as Figure 5 As shown, when the swirl channel 2 of the swirl body 1 is set perpendicular to the outer wall of the swirl body 1, compared with the situation where the swirl body 1 is composed of 6 grooves with a radial angle of 30° At the same time, the six swirl channels 2 are evenly distributed at an angle of 30° along the circumference, the cross-sectional area is 1.2mmX1mm, and the length along the flow direction is 4mm. The sprayed fluid atomization mist cone angle is fixed, and the injection flow rate is fixed, so that the fluid atomization effect is better.

Embodiment 3

[0028] Such as Figure 1-4As mentioned above, when the swirl channel 2 provided on the cyclone body 1 is polished manually, a series of abrasive pastes are used to finely grind the swirl channel 2 to achieve the highest smoothness and structural size consistency. The swirl channel 2 produced by grinding has a low roughness. In the process of performance debugging, visual oil passages often appear, that is, the circumferential uniformity of the atomization degree is poor, and it takes a lot of manual inspection of the swirl channel 2. Finer grinding, but the grinding effect of manual work is unpredictable and the consistency of grinding quality is poor due to uncontrollable human factors, and the individual differences are obvious. Now the present invention adopts advanced chemical grinding and laser processing technology to process a new type of high temperature resistant, resistant The wear-resistant and corrosion-resistant cyclone body 1 has a higher and more excellent proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com