Gold cluster preparation method and application of gold cluster to catalysis of CO2 reaction

A technology of atomic clusters and atoms, which is applied in the field of preparation of gold atomic clusters and catalyzed CO2 reaction, to achieve the effect of high atom economy and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

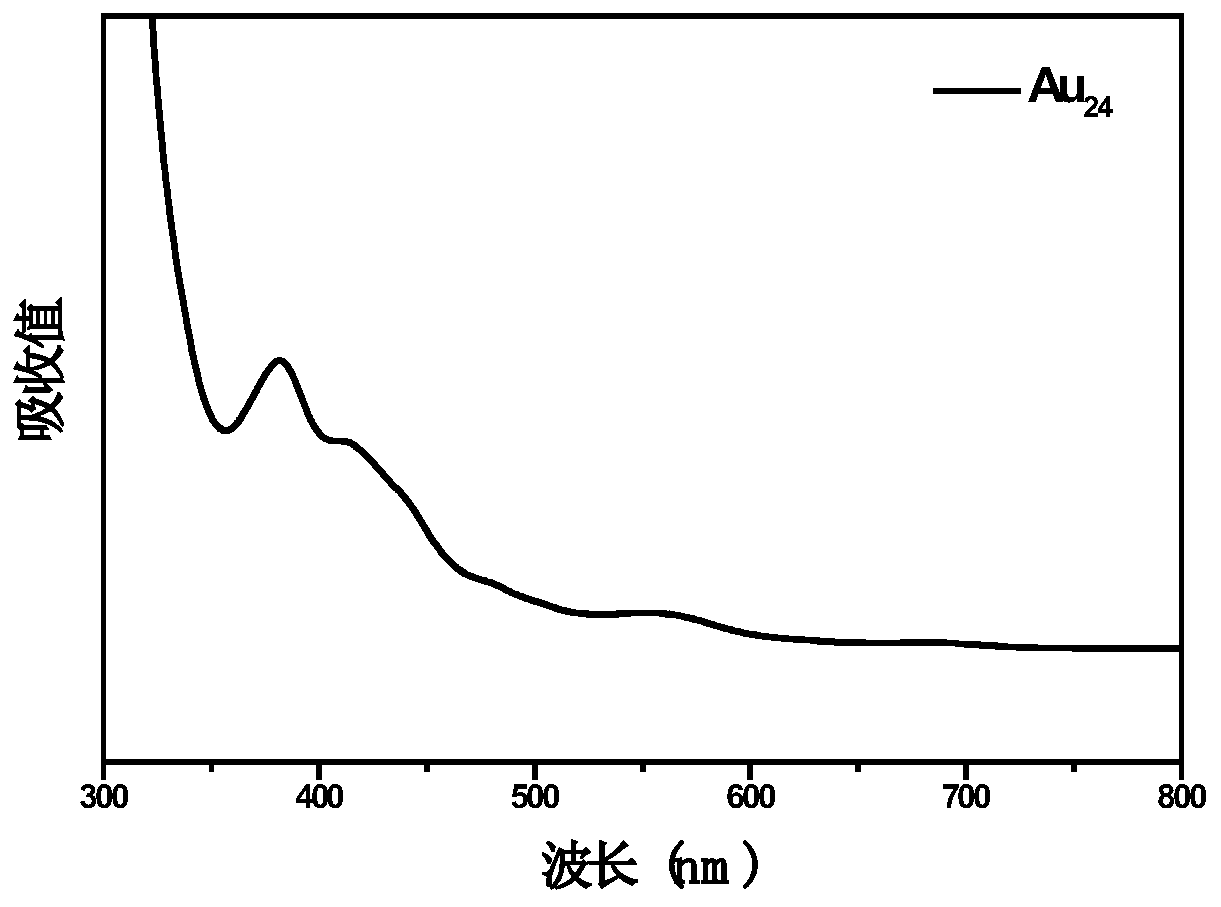

Image

Examples

Embodiment 1

[0037] First, 0.050 grams of tetrachloroauric acid (HAuCl 4 ·3H 2O) was dissolved in 5 milliliters of water, then added to a toluene solution of 10 milliliters of tetraoctyl ammonium bromide (TOAB, 0.087 g; toluene, 10 milliliters), the two-phase solution was vigorously stirred for 10 minutes, the aqueous phase was removed, and 0.100 g of triphenylphosphine (PPh 3 ) into the toluene phase. 5 mL of freshly prepared NaBH 4 ethanol solution (NaBH 4 , 0.0204 g; ethanol, 5 ml) was added quickly, and after stirring for 3.5 hours, the toluene was evaporated to dryness and extracted with 10 ml of dichloromethane. To this extract was added 200 μl of phenethylmercaptan (C 6 h 5 CH 2 CH 2 SH), and then heated to 40 degrees, the reaction was carried out at 40 degrees for 6 hours. Then, 0.5 g of triphenylphosphine (PPh 3 ). The reaction was continued for 24 hours at 40°C. The solvent was evaporated to dryness, washed with hexane, and then extracted with toluene to obtain gold c...

Embodiment 2

[0041] First, 0.062 grams of tetrachloroauric acid (HAuCl 4 ·3H 2 O) was dissolved in 4.4 ml THF, and the solution was stirred in an ice bath for 30 minutes. Under vigorous stirring, 112 μl of phenethylmercaptan (C 6 h 5 CH 2 CH 2 SH) was added to the solution, then the stirring speed was reduced, and the stirring speed was increased after the solution was clarified. 1.5 mL of freshly prepared NaBH 4 Methanol solution (NaBH 4 , 0.06 g; water, 1.5 ml) was added quickly, and after stirring for 3 hours, the ice bath was removed, and the reaction was carried out overnight at room temperature. The solvent was evaporated to dryness, washed with ethanol, and extracted with dichloromethane to obtain gold clusters [Au 25 (PET) 18 ] precursor. Take 0.01 g of the precursor and dissolve it in 0.5 ml of toluene, add 500 microliters of 4-tert-butylthiophenol (TBBT) to the solution, and react at 80 degrees for two hours. The solution was then evaporated to dryness, washed, and ext...

Embodiment 3

[0044] First, 0.100 grams of tetrachloroauric acid (HAuCl 4 ·3H 2 O) was dissolved in 5 ml of water, then added to a toluene solution of 10 ml of tetraoctylammonium bromide (TOAB, 0.200 g; toluene, 10 ml), the two-phase solution was vigorously stirred for 15 minutes, the aqueous phase was removed, and With vigorous stirring, 0.200 g of triphenylphosphine (PPh 3 ) into the toluene phase. 5 mL of freshly prepared NaBH 4 ethanol solution (NaBH 4 , 0.0204 g; ethanol, 5 ml) was added quickly, and after stirring for 3.5 hours, the toluene was evaporated to dryness and extracted with 12 ml of dichloromethane. To this extract was added 200 μl of phenethylmercaptan (C 6 h 5 CH 2 CH 2 SH), and then heated to 40 degrees, the reaction was carried out at 40 degrees for 6 hours. Then, 1.200 g of PPh was added to the solution 3 . The reaction was continued for 24 hours at 40°C. The solvent was evaporated to dryness, washed with hexane, and then extracted with toluene to obtain go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com