A light gear for vehicle and its manufacturing process

A gear manufacturing and gear technology, applied in the field of light vehicle gear and its manufacturing process, can solve the problems of insurmountable decarburization tendency, insignificant strengthening effect, high energy consumption of blank forging, and achieve reduction of friction coefficient, process time saving, The effect of low processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

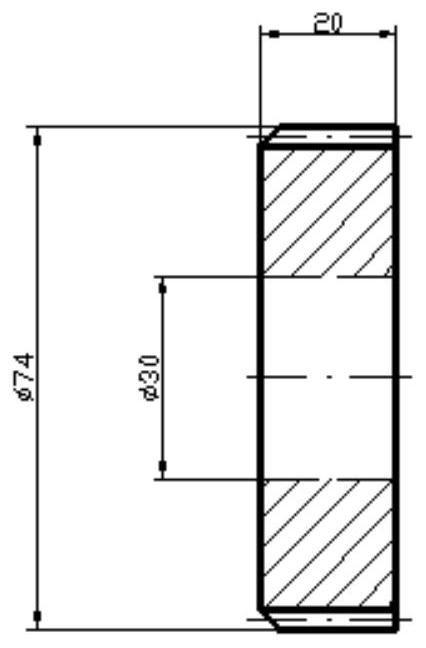

[0057] Such as figure 2 As shown, a light gear for a vehicle has a center hole diameter of d=30mm, a length of L=20mm, and an outer diameter of the gear of D=74mm.

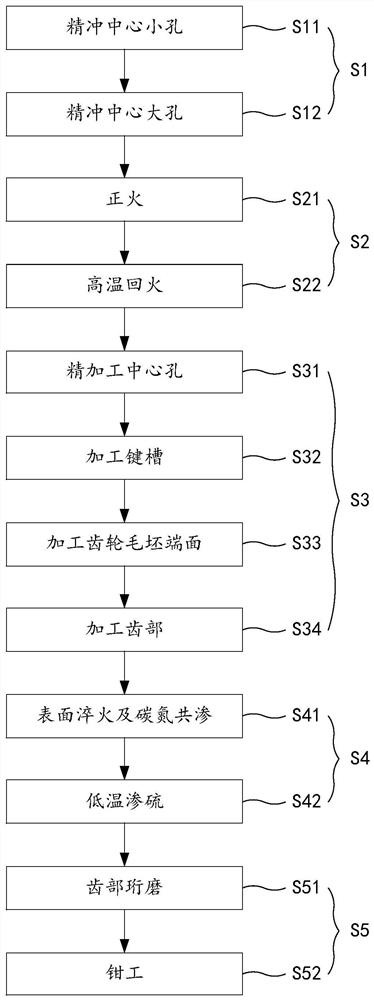

[0058] Such as figure 1 As shown, the process of manufacturing the above gears includes:

[0059] S1. Roughly machining the gear raw material to obtain a gear blank with a large central hole.

[0060] Step S1 specifically includes the following sub-steps:

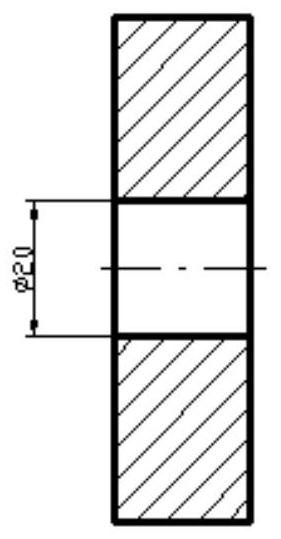

[0061] S11. Use the fine blanking process to process a central small hole on the gear raw material. The diameter of the central small hole is 20mm, such as image 3 shown.

[0062] S12. Use the fine blanking process to expand the central small hole into a central large hole. The diameter of the central large hole is slightly less than 30mm, leaving a machining allowance for the subsequent boring. The allowance is about 1mm, such as Figure 4 shown.

[0063] In the above process, two fine blanking processes are used instead of traditional forging, which gre...

Embodiment 2

[0083] Such as Figure 5 As shown, the difference from Embodiment 1 is that in this embodiment, step S4 specifically includes the following sub-steps:

[0084] S41. This step is sulfurizing treatment. Specifically, when using the plasma beam to heat the gear semi-finished product, the surface of the tooth portion of the gear semi-finished product is heated to 170° C., and then kept for 2 hours to complete the sulfurizing treatment to obtain a sulfidation treatment with a thickness of 10-20 μm. sulfur layer.

[0085] S42. This step is a surface quenching treatment. Specifically, use a plasma beam to continue heating the teeth of the semi-finished gear to 450°C and keep it warm for 1 hour. During this process, nitrogen is used as a protective gas, and a small amount of methane is added to the nitrogen for the surface. Oxidation-free protection of quenching while achieving carbonitriding. Nitrogen was added at a rate of 75 ml / min, and methane was added at a rate of 15 ml / min. ...

Embodiment 3

[0087] A manufacturing process of light gears for vehicles, the diameter of the central hole of the gear is d=35mm, the length L=25mm, and the outer diameter of the gear is D=85mm. Including the following steps:

[0088] S1. Roughly machining the gear raw material to obtain a gear blank with a large central hole.

[0089] Step S1 specifically includes the following sub-steps:

[0090] S11, using a fine blanking process to process a central small hole on the gear raw material, the diameter of the central small hole is 25 mm.

[0091] S12. Enlarging the central small hole into a central large hole by adopting a fine blanking process, the diameter of the central large hole is slightly smaller than 35mm, leaving a machining allowance for subsequent boring, and the allowance is 1mm.

[0092] S2, performing heat treatment on the gear blank.

[0093] Step S2 specifically includes the following sub-steps:

[0094] S21. This step is normalizing treatment. Specifically, the gear bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com