Poured-in type quenching technology and quenching equipment

A quenching equipment and process technology, applied in the field of influx quenching process and quenching equipment, can solve the problems of different residence time of hot workpieces, heavy weight of a single leaf spring, difficulty in eliminating environmental pollution, etc., so as to shorten the production cycle of products , The effect of improving strength and hardness, improving product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

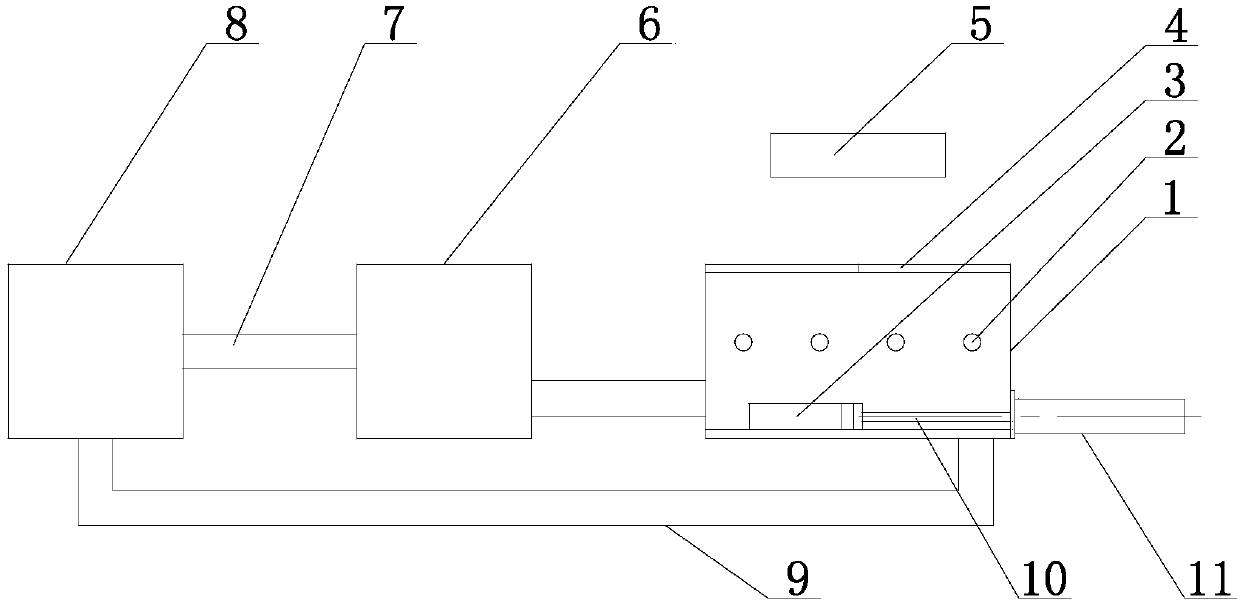

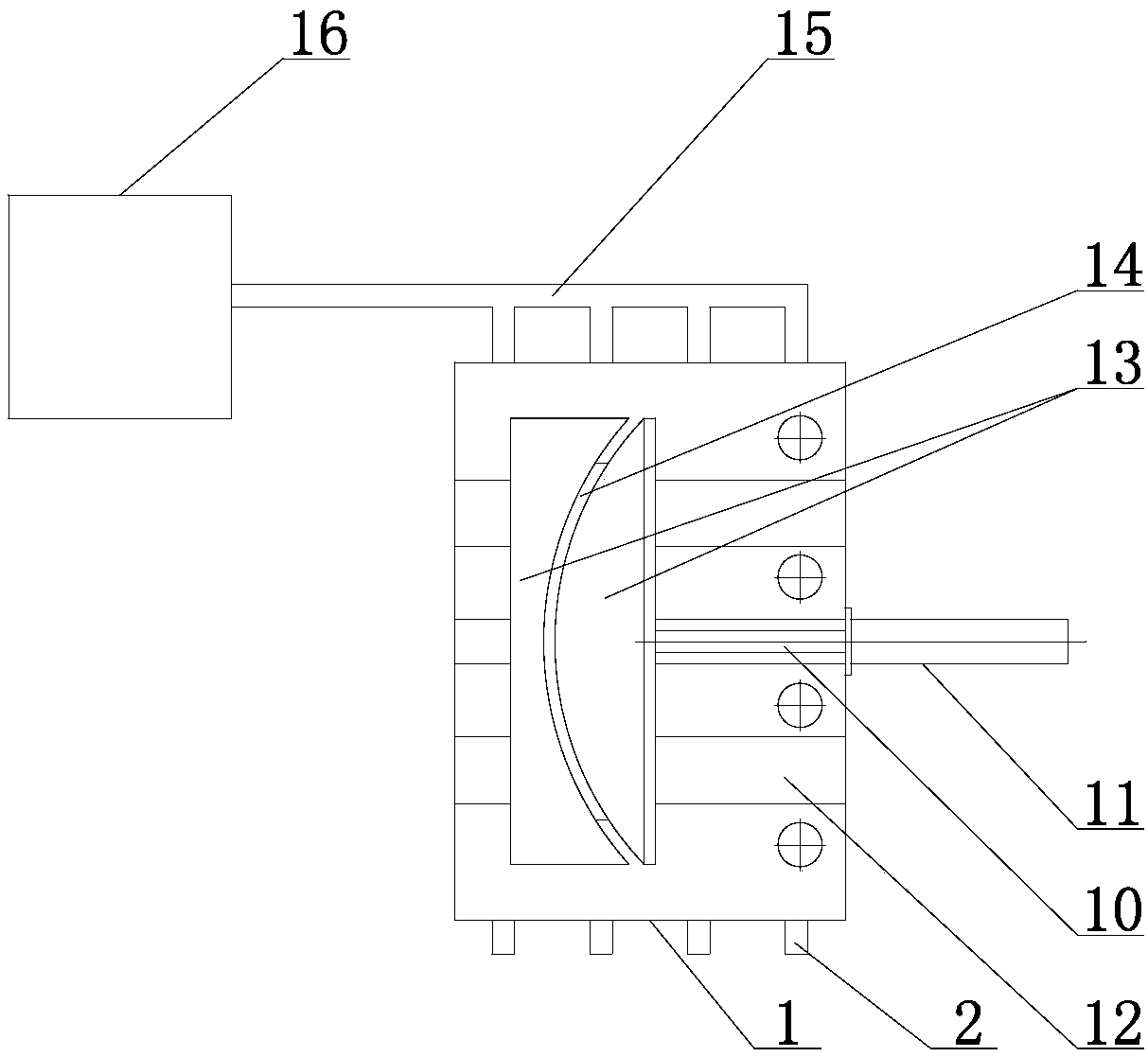

[0034] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0035] Such as figure 1 , 2 As shown, the quenching equipment of the present invention includes a quenching furnace, a manipulator 5, a quenching tank 1, a quenching fixture 3, a fume purification treatment system 16 and a quenching medium cooling system 8. The quenching fixture 3 is installed in the quenching tank 1, and each group of quenching The clamp 3 is composed of two clamps 13, one of which is connected to the displacement drive mechanism. The two clamps 13 of the quenching clamp 3 can form a space that matches the shape of the leaf spring 14. When the two clamps 13 are matched, the The leaf spring 14 is clamped and positioned and formed by hot pressing; a quenching box cover 4 is installed on the top of the quenching tank 1 to close the quenching tank 1; the side wall of the quenching tank 1 is provided with a quenching medium inlet, an air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com