Annealing furnace strip temperature process transition control method and device

A transition control and annealing furnace technology, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of short transition time, high randomness, low efficiency, etc. The effect of controlling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Such as figure 1As shown, this embodiment provides a method for controlling the temperature transition of an annealing furnace, which is applied to industrial control equipment, including:

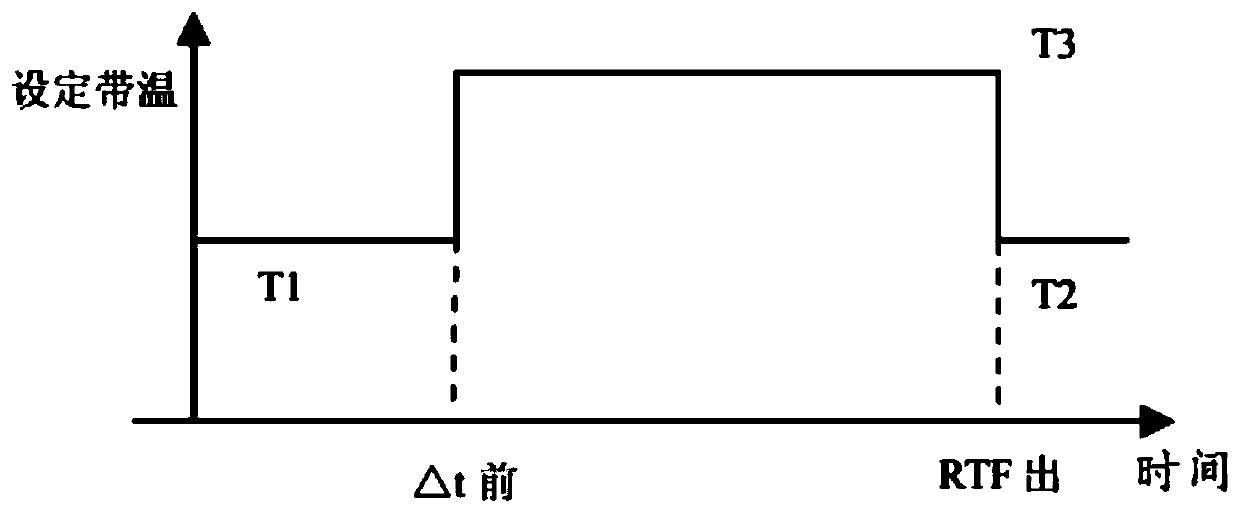

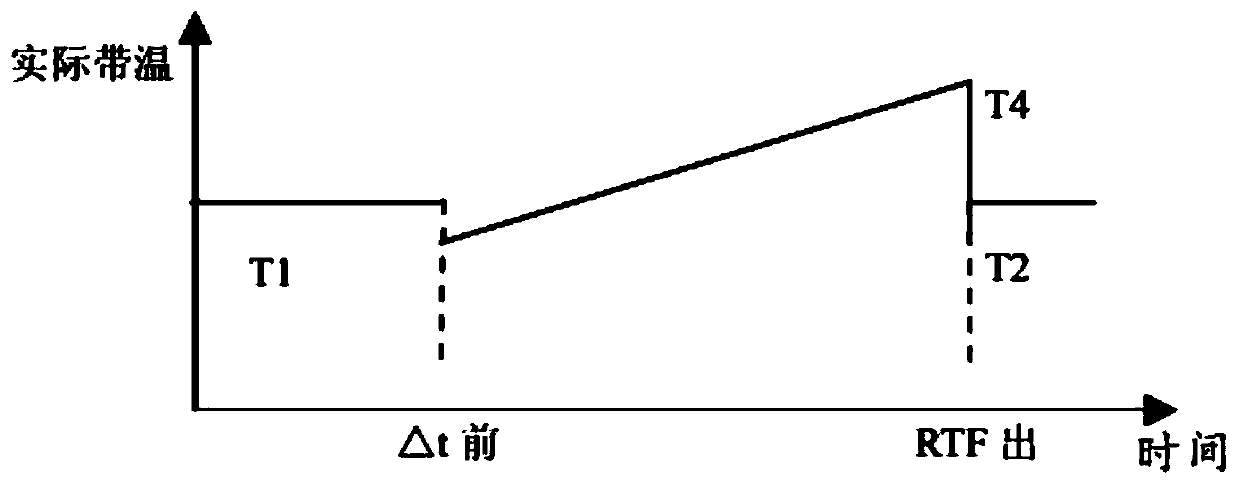

[0051] Step S101: During the production switching process of two strips with different specifications, obtain the thickness value d1 of the strip steel of the previous specification and the set temperature value T1 of RTF (radiant tube heating section), and the thickness value d2 of the strip steel of the latter specification and RTF set temperature value T2. Among them, RTF (radiant tube heating section) is located at the exit of the annealing furnace.

[0052] In a specific implementation process, the industrial control equipment may be an industrial computer for controlling the annealing furnace.

[0053] Specifically, a control model can be set in the industrial computer, and the program code corresponding to the method in this embodiment is integrated in the control model, so...

Embodiment 2

[0080] Such as Image 6 As shown, this embodiment provides an annealing furnace temperature transition control device 200, including:

[0081] The obtaining unit 201 is used to obtain the thickness value d1 of the strip steel of the previous specification, the RTF set temperature value T1 of the radiant tube heating section, and the thickness value of the strip steel of the latter specification during the production switching process of two strip steels with different specifications d2 and RTF set temperature T2, the radiant tube heating section is located at the exit of the annealing furnace;

[0082] The control unit 202 is used to switch the production process according to the thickness value d1 and the RTF setting temperature value T1 of the strip steel of the previous specification, and the thickness value d2 and the RTF setting temperature value T2 of the strip steel specification of the latter specification. The RTF set temperature value T3 in the control.

[0083] Fu...

Embodiment 3

[0094] This embodiment provides an industrial control device, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the following steps can be implemented:

[0095]In the production switching process of two strips with different specifications, obtain the thickness value d1 of the strip steel of the previous specification and the RTF set temperature value T1 of the radiant tube heating section, as well as the thickness value d2 and the RTF set temperature value of the strip steel of the latter specification value T2, the radiant tube heating section is located at the exit of the annealing furnace; the temperature value T1 is set according to the thickness value d1 and RTF of the strip steel of the previous specification, and the thickness value d2 and RTF of the strip steel of the latter specification The set temperature value T2 controls the RTF set temperature value T3 during the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com