Pretreatment steam extraction method for rosin, arabinogalactan and dihydroquercetin in larch wood powder

A technology of arabinogalactan and dihydroquercetin, which is applied in the field of extracting pine resin, can solve the problems of not very pure products, long production cycle, and difficult operation, so as to shorten the production cycle, simplify production steps, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

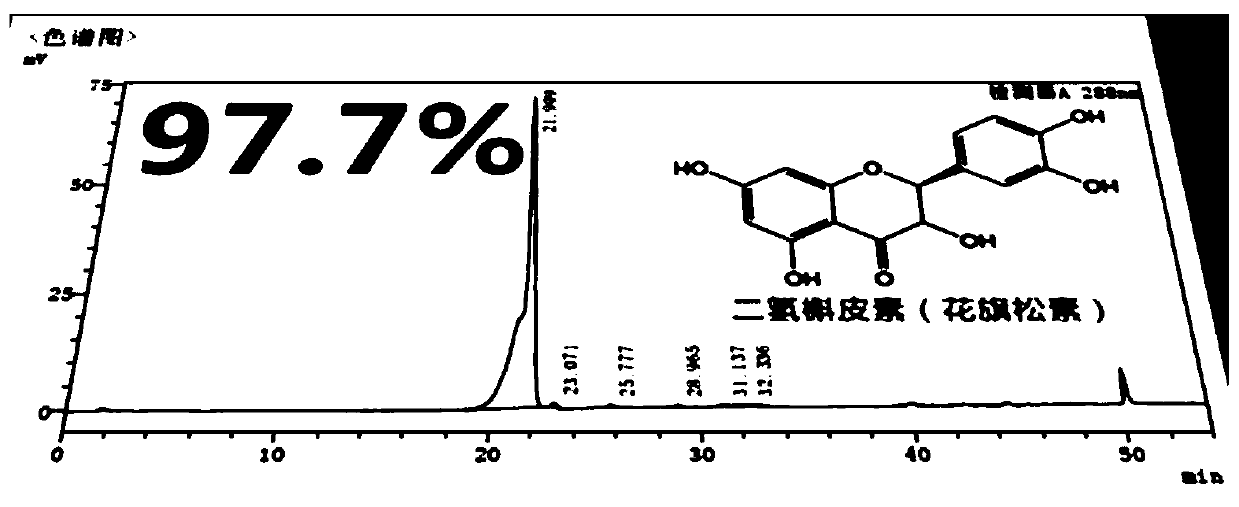

Embodiment 1

[0039] 100000g of Siberian larch wood powder containing 20% water was added to 1000L of purified water, stirred and leached at room temperature for 5 hours, filtered out the filtrate containing arabinogalactan, and freeze-dried the filtrate to obtain arabinogalactan. The water-washed larch wood powder is first added with a steam pressure of 0.2MPa and a temperature of 125°C°, steamed for 2h, filtered to extract the distillate, and concentrated to an extract under reduced pressure (minus 0.8 atm) at 50°C to obtain 4200g of extract. The concentrated extract was suspended and treated with 95°C, 50L purified water. After the extract is basically dissolved, it is filtered at a temperature above 60°C. After filtering out the water-insoluble matter, it is allowed to stand, cooled to room temperature, and the precipitated precipitate is filtered, and then left to stand until no precipitate is precipitated. Combine the solutions, use 95°C and 30L purified water for another suspension ...

Embodiment 2

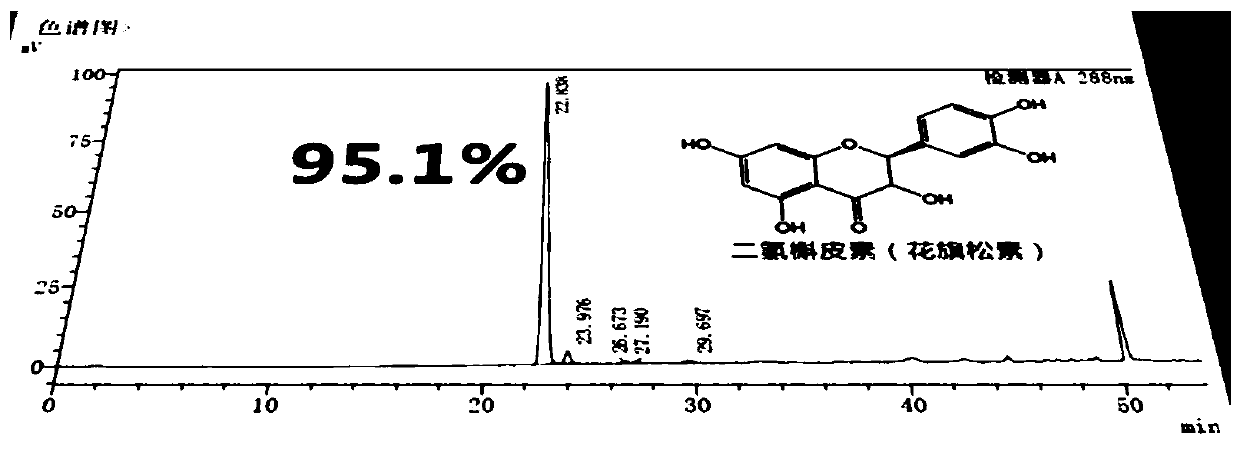

[0041] 100kg of Siberian larch wood powder with 20% water content was added to 1500L of purified water, stirred and leached at room temperature for 6 hours, and the filtrate containing arabinogalactan was filtered out. After spray drying the filtrate, arabinogalactan is obtained. The washed larch wood powder is first added with a steam pressure of 0.2 MPa and a temperature of 130° C., steamed for 2.5 hours, filtered to extract the distillate, and concentrated to an extract at 50° C. at minus 0.8 atmosphere to obtain 4250 g of extract. The concentrated extract was suspended and treated with 95°C, 50L purified water. After the extract is basically dissolved, it is filtered at a temperature above 60°C. After filtering out the water-insoluble matter, it is allowed to stand, cooled to room temperature, and the precipitated precipitate is filtered, and then left to stand until no precipitate is precipitated. Combine the solutions, use 95°C and 30L purified water for another suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com