Low-temperature instant agar and preparation method thereof

An instant and agar technology, which is applied in the field of low-temperature instant agar and its preparation, can solve the problems of reducing the purity and quality of agar, limiting agar, increasing protein content, etc., and achieves the improvement of preparation technology and high-value utilization. The effect of quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

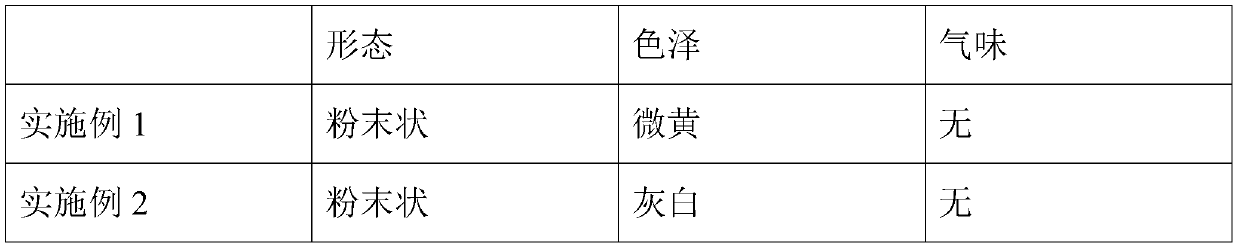

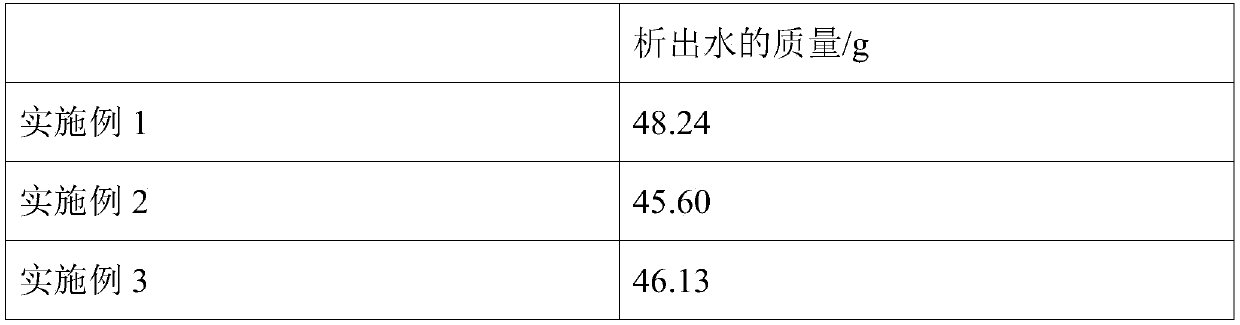

Embodiment 1

[0060] A preparation method of low-temperature instant agar, comprising the following steps:

[0061] (1) Alkali treatment: get seaweed 100g (for selection of Grapefruit in Example 1) and wash, then soak in the NaOH solution that concentration is 5wt%, and the material-to-liquid ratio of described Gracilaria and NaOH solution is 1:20g / mL, stirred evenly, heated for constant temperature treatment, the temperature of constant temperature treatment was 70 °C, the time of constant temperature treatment was 3 h, and the precipitate was filtered to obtain the seaweed after alkali treatment;

[0062] (2) washing: the seaweed after the alkali treatment described in step (1) is filtered and washed, and the pH of the last washing solution is 7.0 to obtain the seaweed after the first washing;

[0063] (3) bleaching: the seaweed after the first washing described in step (2) is soaked in a bleaching agent whose mass percent concentration is 0.25w% (select NaClO solution here), and the sea...

Embodiment 2

[0071] A preparation method of low-temperature instant agar, comprising the following steps:

[0072] (1) Alkali treatment: get seaweed 100g (embodiment 2 selects Grapefruit) and wash, then soak in the NaOH solution that concentration is 6wt%, and the material-to-liquid ratio of described Grapevine and NaOH solution is 1:20g / mL, stirred evenly, heated for constant temperature treatment, the temperature of constant temperature treatment was 80 °C, the time of constant temperature treatment was 3 h, and the precipitate was filtered to obtain the seaweed after alkali treatment;

[0073] (2) washing: the seaweed after the alkali treatment described in step (1) is filtered and washed, and the pH of the last washing solution is 7.5 to obtain the seaweed after the first washing;

[0074] (3) bleaching: the seaweed after the first washing described in step (2) is soaked in a bleaching agent whose mass percent concentration is 0.40w% (select NaClO solution here), and the seaweed after...

Embodiment 3

[0082] A preparation method of low-temperature instant agar, comprising the following steps:

[0083] (1) alkali treatment: get seaweed 100g (embodiment 3 selects Grapefruit) and wash, then soak in the NaOH solution that concentration is 7wt%, and the material-to-liquid ratio of described Grapevine and NaOH solution is 1:20g / mL, stirred evenly, heated for constant temperature treatment, the temperature of constant temperature treatment was 90 °C, the time of constant temperature treatment was 4 h, and the precipitate was filtered to obtain the seaweed after alkali treatment;

[0084] (2) washing: the seaweed after the alkali treatment described in step (1) is filtered and washed, to the pH of the last washing solution to be 8.5, to obtain the seaweed after the first washing;

[0085] (3) bleaching: the seaweed after the first washing described in step (2) is soaked in a bleaching agent whose mass percent concentration is 0.60w% (select NaClO solution here), and the seaweed af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com